Multifunctional highway maintenance vehicle capable of automatically conveying material

A multifunctional, maintenance vehicle technology, applied in the direction of roads, roads, road repairs, etc., can solve the problems of low automation, hidden dangers, long heating preparation time, etc., to achieve high automation, safe construction process, and strong maintenance pertinence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solution of the present invention will now be further described in conjunction with the drawings and embodiments.

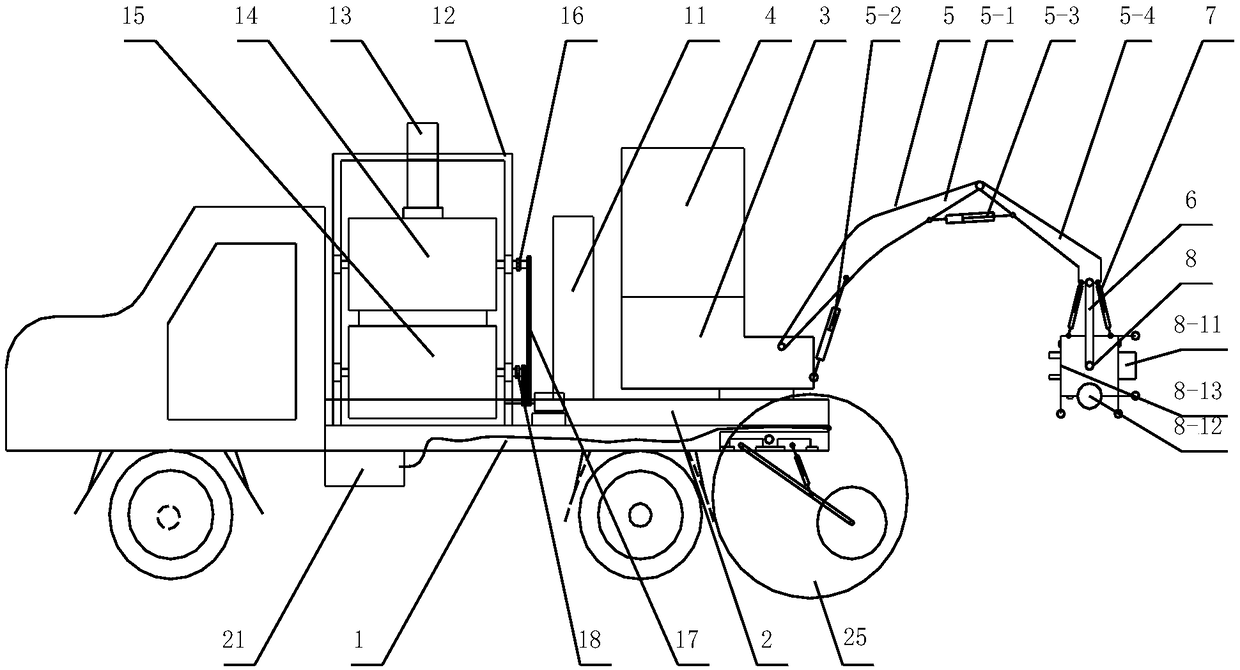

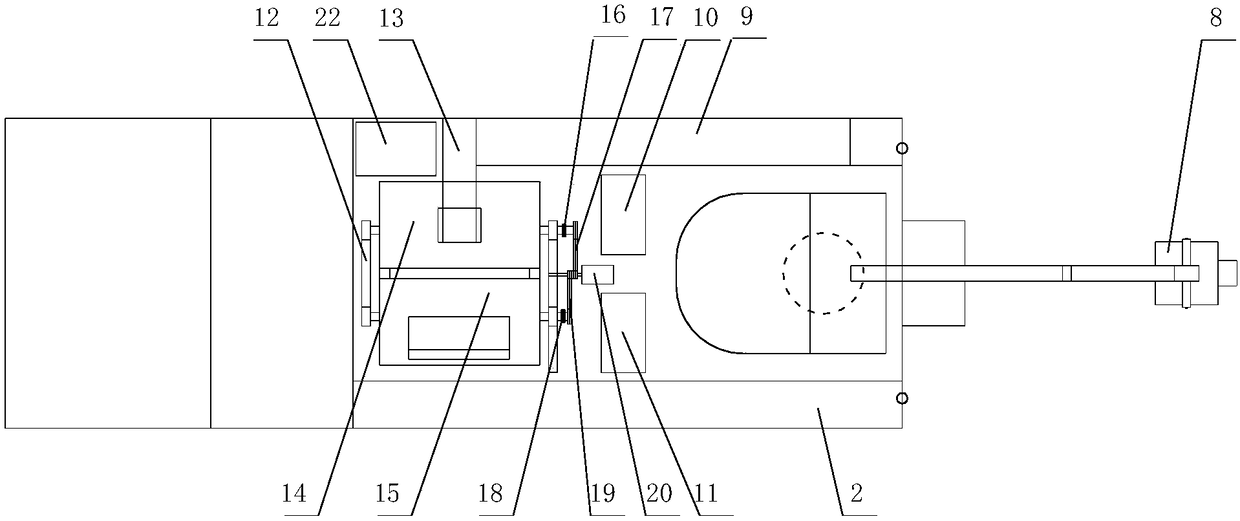

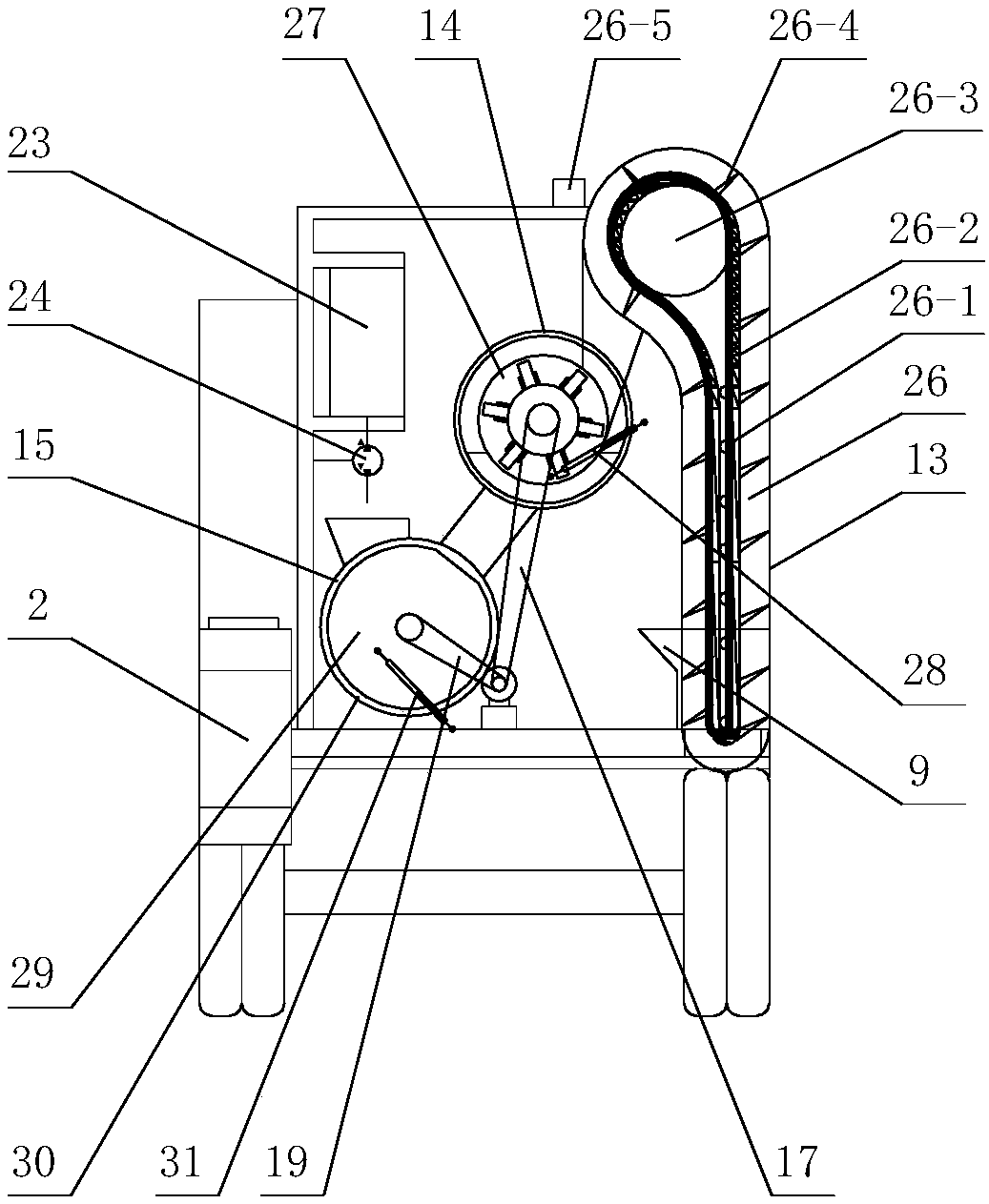

[0038] see figure 1 and figure 2 , on both sides of the carriage on the chassis 1 of the maintenance vehicle, there are protruding waste conveying troughs 9 and mixed material conveying troughs 2, a balance turntable 3 is installed at the tail of the chassis 1, and a control system 4 is installed on the balance turntable 3 And the joint mechanical arm 5, the control system 4 is used to realize the automatic control of the whole maintenance vehicle. The articulated manipulator 5 is hinged on the side of the balance turntable 3. The articulated manipulator 5 of this embodiment includes a first arm 5-1 and a second arm 5-4. The first arm 5-1 passes through the first hydraulic cylinder 5-2. Connected with the balance turntable 3, the amplitude of the first arm 5-1 is controlled by the first hydraulic cylinder 5-2, the second arm 5-4 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com