Internet of things-based satellite production site real object directional perception method

An Internet of Things and satellite technology, applied in the direction of comprehensive factory control, instruments, comprehensive factory control, etc., can solve the problems of long production cycle, material loss, waste, etc., achieve accurate matching between physical objects and data, improve management and control capabilities, and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

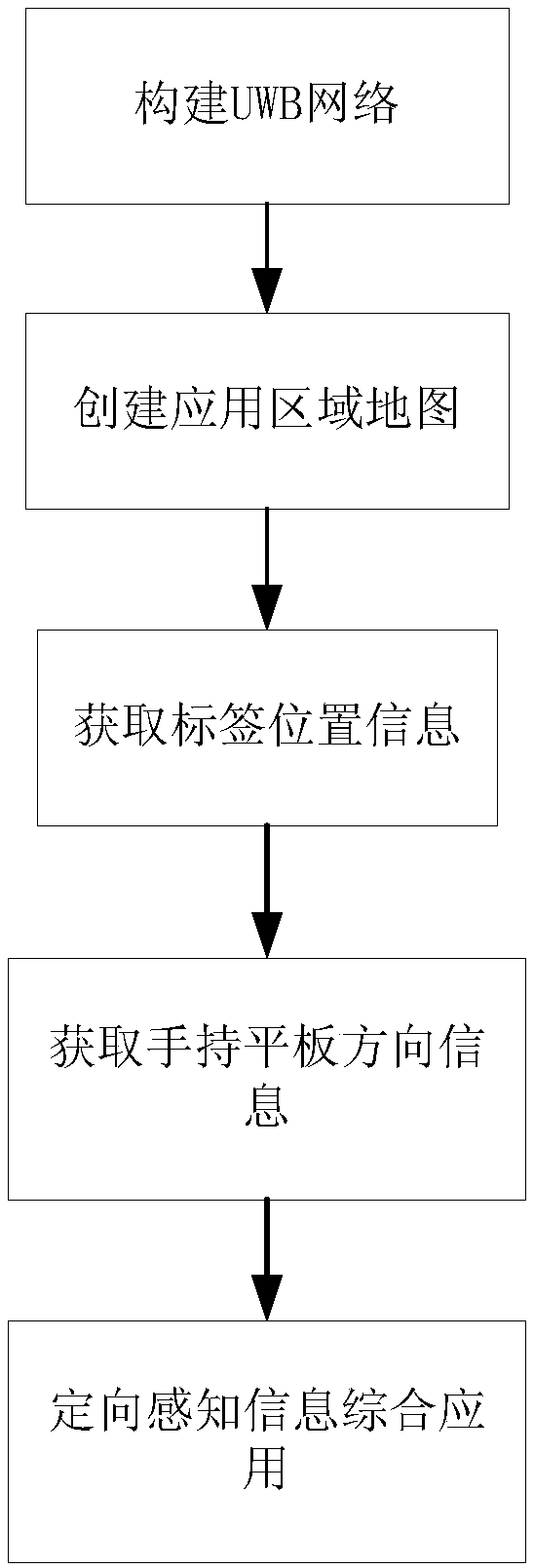

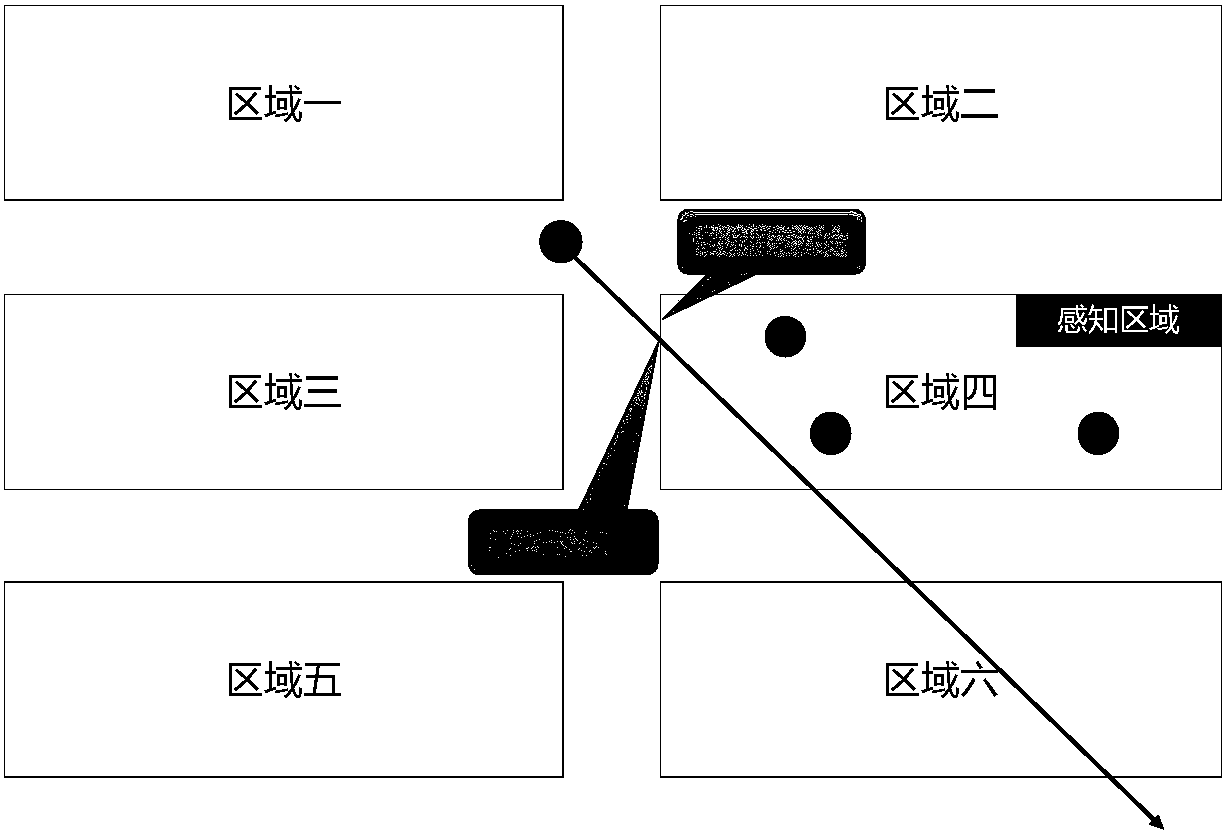

[0022] Aiming at the deficiencies of the prior art, the present invention provides a method for directional sensing of objects in a satellite production site based on the Internet of Things. By arranging UWB positioning base stations, the UWB positioning technology is used to obtain workshop resources (materials, personnel, equipment, and processing (inspection) tasks) and logistics transportation tools), obtain the direction information corresponding to the pad through the built-in compass module of the pad server or the compass APP function module, and combine the above resource location information and the direction information pointed by the pad server to ensure the direction pointed by the pad server. The resources in the fan-shaped area of the satellite can be sensed and identified, so that the resource information of the satellite production workshop can be quickly located and the resources can be perceived with subjective awareness (what you see is what you get), and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com