Nuclear-island-plant fair-faced-concrete-wall-surface automatic-repairing system and realization method thereof

A clear-faced concrete and automatic repair technology, which is applied in image data processing, instruments, character and pattern recognition, etc., can solve the problems of wasting manpower, low work efficiency, and endangering workers' lives and health, so as to achieve high work efficiency, guarantee life and health, Labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

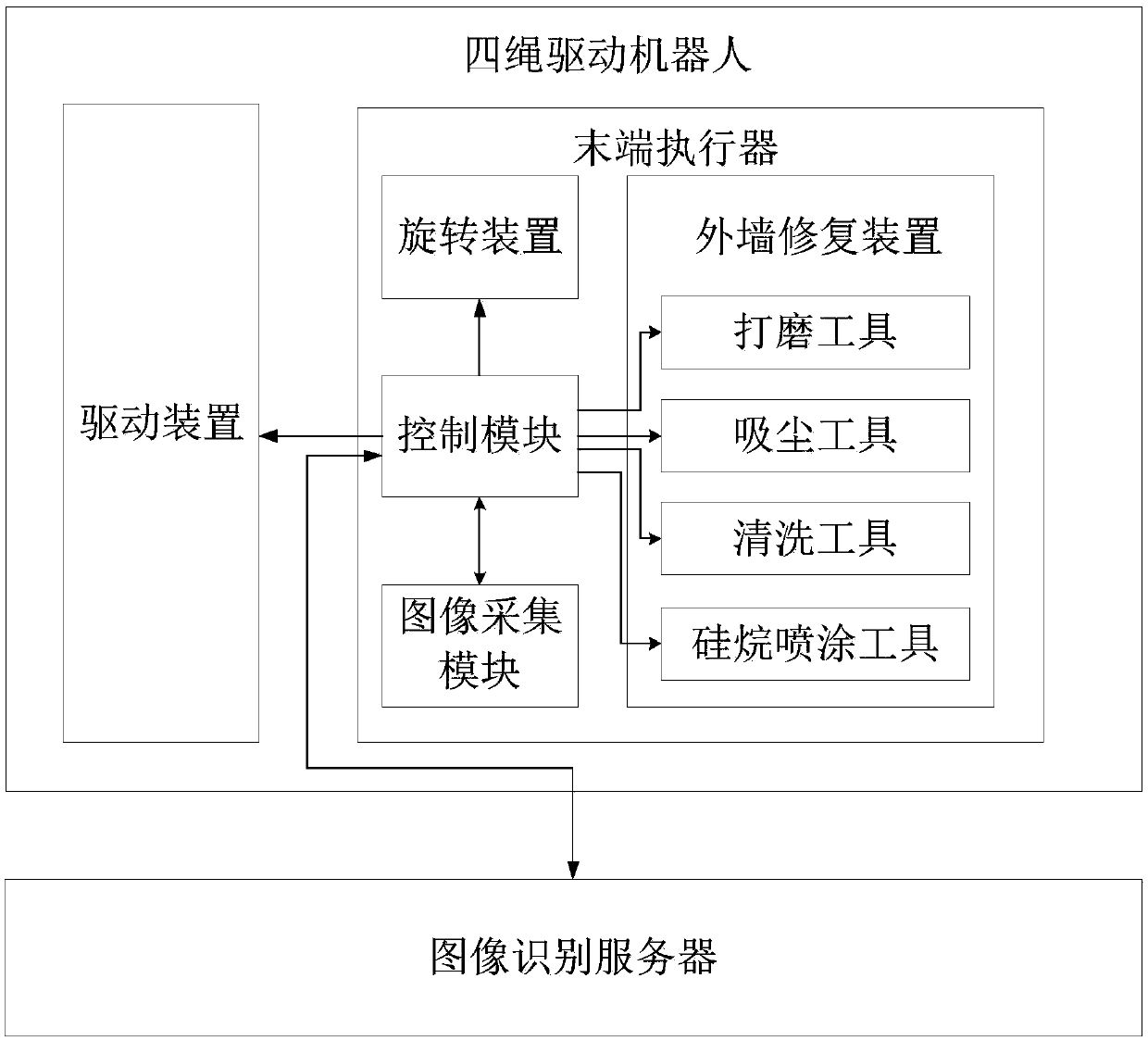

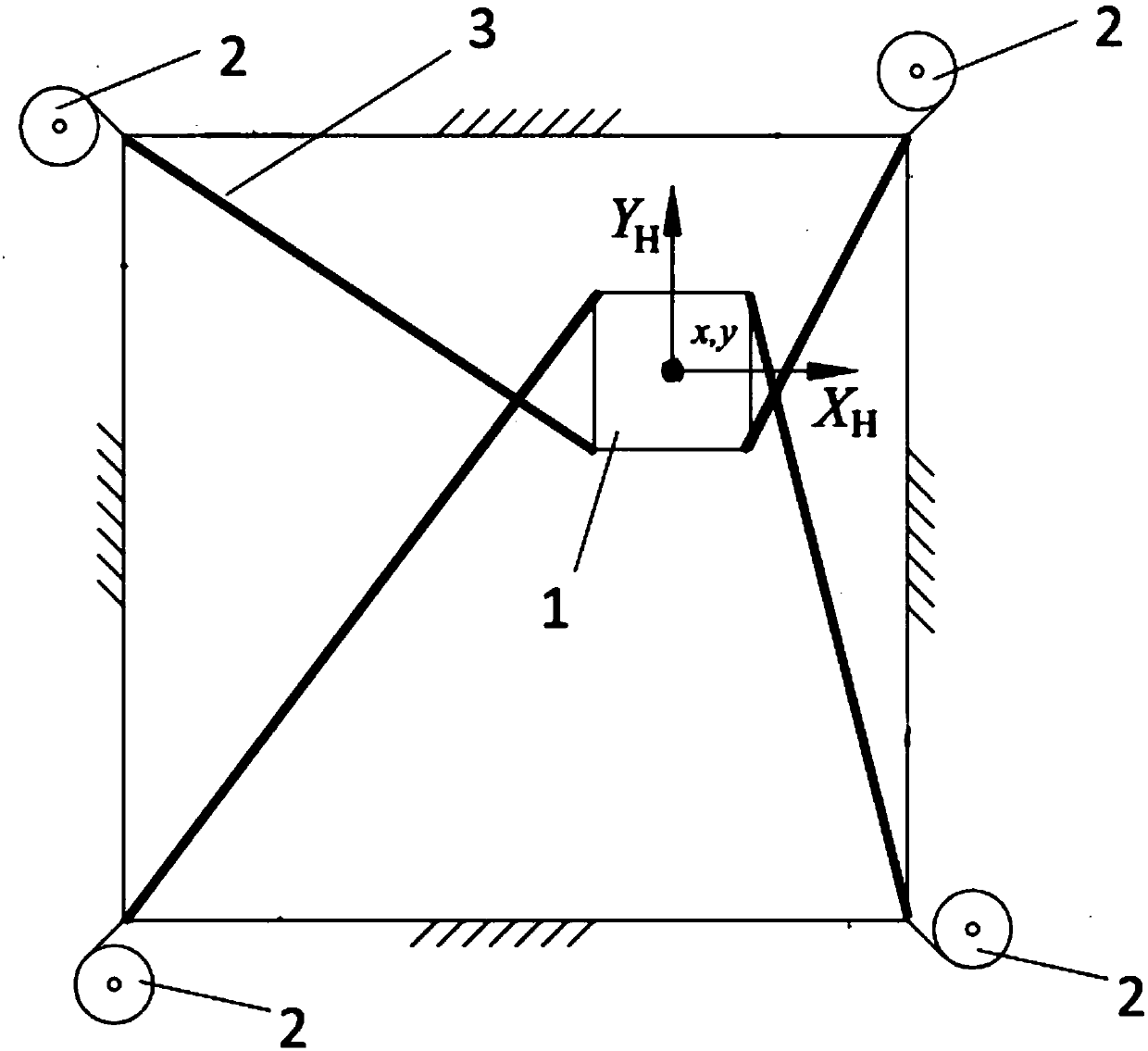

[0079] In order to solve the problems currently existing in the technology of repairing the wall surface of the nuclear island powerhouse, this embodiment proposes an automatic repair system for the fair-faced concrete outer wall of the nuclear island powerhouse. Such as figure 1 As stated, the system includes: an image recognition server and a four-rope-driven robot.

[0080] Among them, the image recognition server is used to perform image processing and identify the location of the wall of the nuclear island plant that needs to be repaired, and generate control signals to control the four-rope-driven robot to complete the repair work.

[0081] The four-rope-driven robot is used to climb the wall of the nuclear island plant, collect images of the wall of the nuclear island plant, and repair the wall of the nuclear island plant according to the control signal of the image recognition server;

[0082] The image recognition server is connected with the four-rope driven robot; ...

Embodiment 2

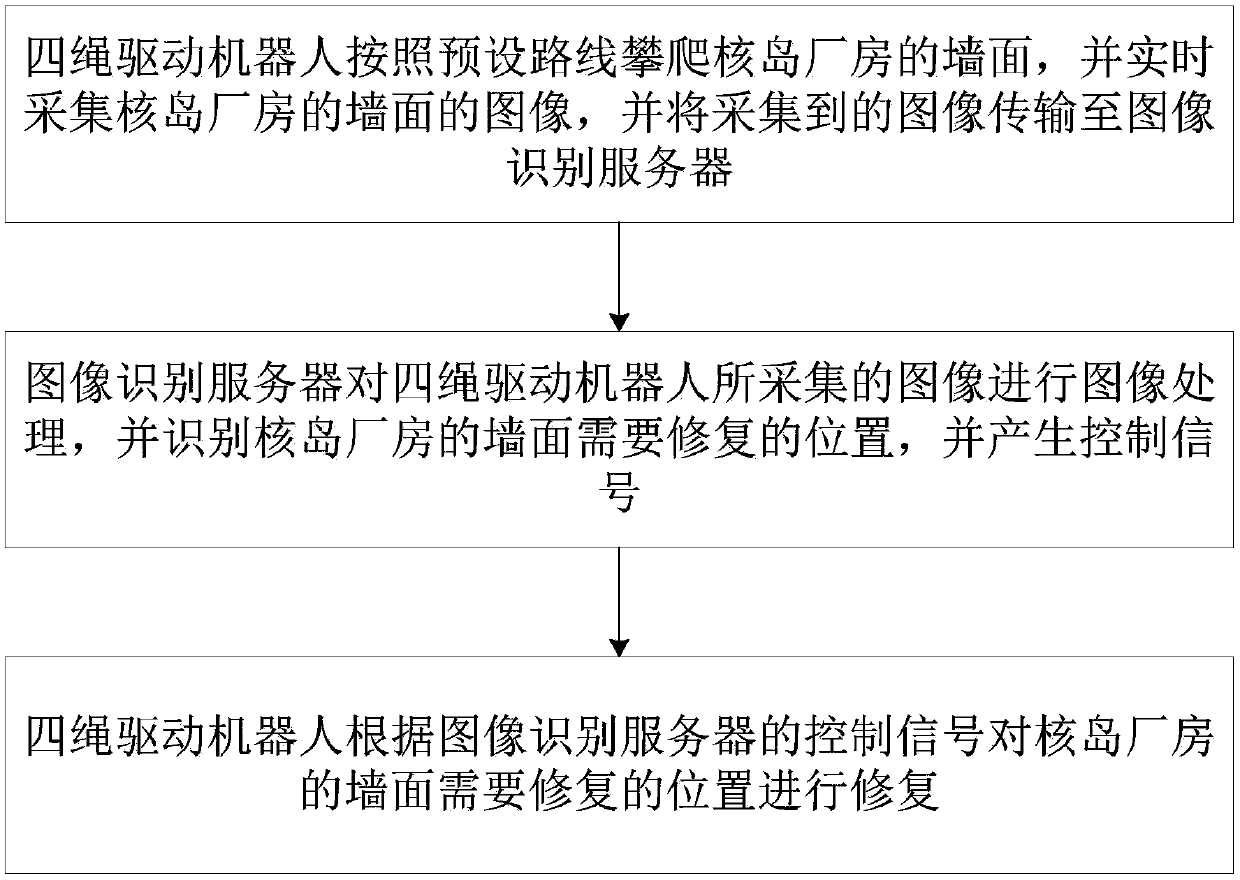

[0094] In order to solve the problems currently existing in the technology of repairing the walls of nuclear island powerhouses, this embodiment proposes an implementation method for an automatic repair system for fair-faced concrete exterior walls of nuclear island powerhouses. Figure 4 , the method includes the following steps:

[0095] S1. The four-rope-driven robot climbs the wall of the nuclear island plant according to a preset route, collects images of the wall of the nuclear island plant in real time, and transmits the collected images to the image recognition server.

[0096] S2. The image recognition server performs image filtering processing on the image collected by the four-rope-driven robot to obtain an image to be tested.

[0097] S3. Use the non-defective wall image to train the image recognition server, and obtain the average value of the average gray level difference of the sub-images of the non-defective wall image, and the gray level standard deviation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com