Chip module with excellent heat dissipation performance and fabrication method of chip module

A heat dissipation and chip technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, semiconductor devices, etc., can solve the problem of heat dissipation reduction, achieve less voids, good welding effect, and meet the requirements of size and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

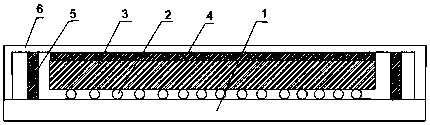

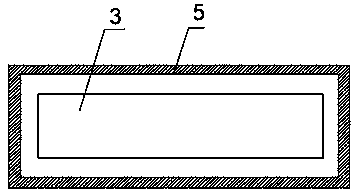

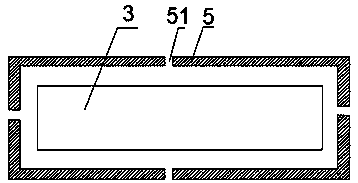

[0028] The technical solution of the present invention is specifically described below in conjunction with the embodiments. The present invention discloses a chip assembly with good heat dissipation, combined with Figure 1-Figure 3 As shown, the chip assembly is similar to the prior art, and both include a chip body 3 connected to the substrate 1 through solder balls 2, a heat-dissipating indium sheet 4 is arranged above the chip body 3 and packaged on the heat-dissipating indium sheet 4 6 on the heat sink cover.

[0029] Different from the prior art, a dam 5 is arranged around the chip body 3, and a gap is provided between the dam 5 and the chip body 3, and the gap between the dam 5 and the heat dissipation chip is 0-2000μm. The dam 5 can be constructed by using materials such as epoxy resin glue and organic silicon through a glue dispenser, a sprayer or a 3D printer.

[0030] The dam in the present invention refers to a protective ring formed around the chip around the ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com