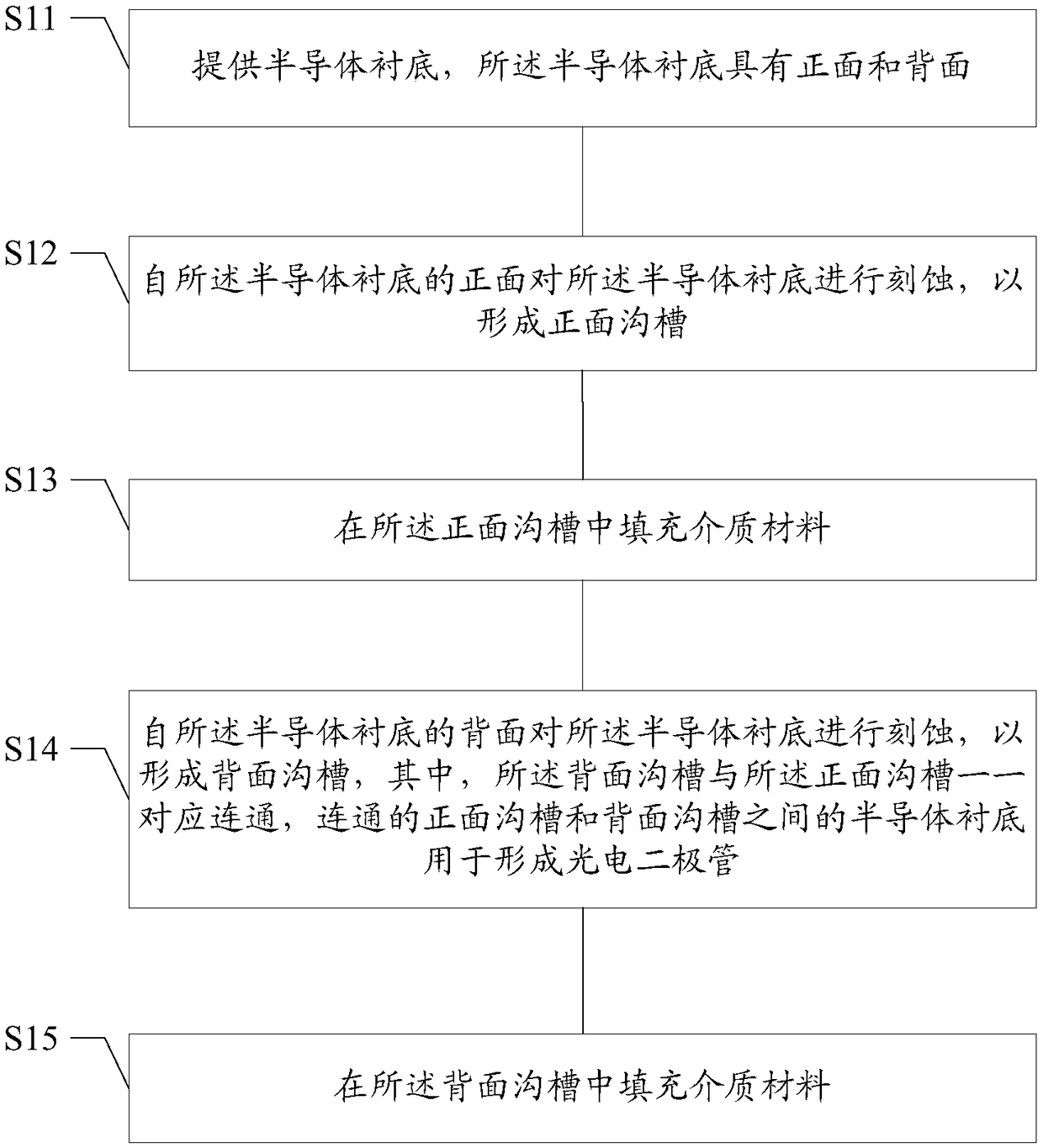

Image sensor and forming method thereof

An image sensor and patterning technology, which is applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., can solve the problems of low full well capacity, electrical crosstalk, and insufficient DTI depth, etc., to improve full well capacity, increase thickness, reduce Effects of Electrical Crosstalk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

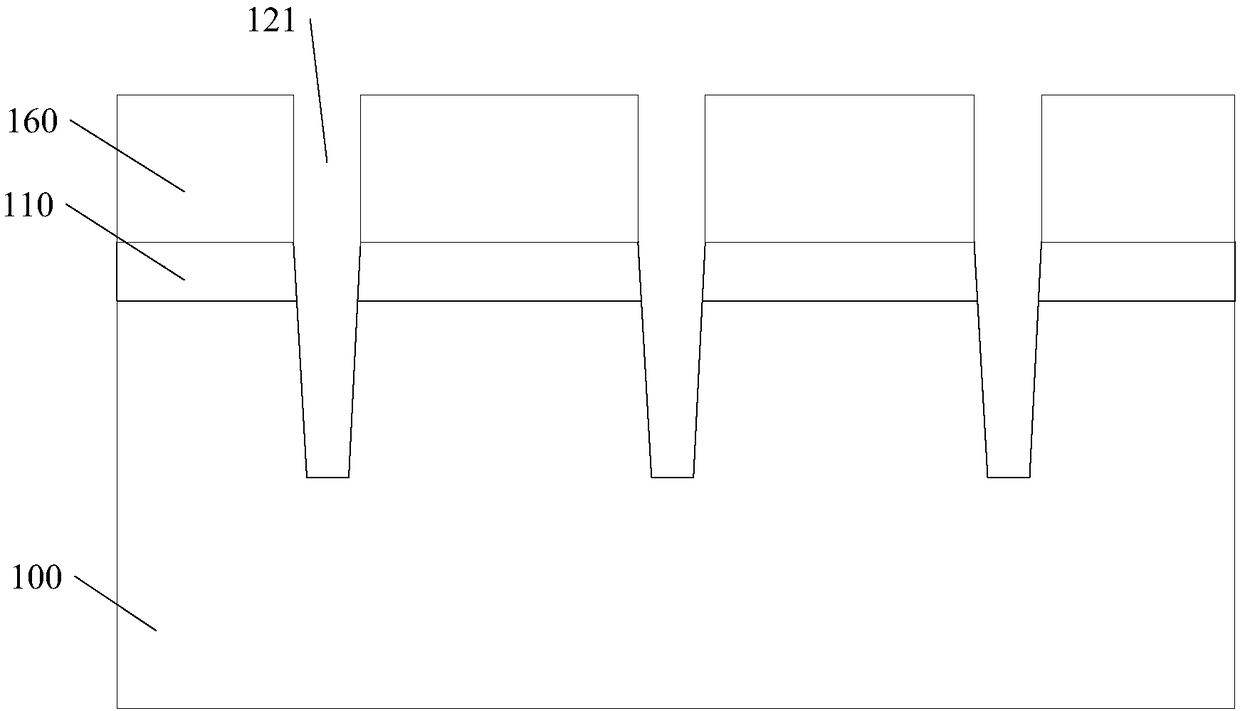

Embodiment Construction

[0022] In the prior art, in order to prevent photocarriers in different regions from diffusing to adjacent regions, it is necessary to form DTI inside the semiconductor substrate. However, due to the insufficient depth of the DTI, serious electrical crosstalk is caused, and due to the limitation of the depth of the DTI, the thickness of the photodiode is insufficient, resulting in a too low full well capacity. Specifically, full well capacity is the maximum charge a pixel can hold before saturation leading to signal degradation. When the charge in a pixel exceeds the saturation level, the charge begins to fill adjacent pixels, a process known as blooming.

[0023] The inventors of the present invention have found through research that in the prior art, DTI is only formed on one side of a semiconductor substrate, and it is difficult to form a very deep DTI due to the limitation of existing process capabilities. Specifically, for example, it is difficult to form very deep DTI t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com