A method to improve the pm of iron ore sintering flue gas electric dust removal process 2.5 The method of removal efficiency

A technology for sintering flue gas and removal efficiency, which is applied in the field of improving the removal efficiency of PM2.5 in the electric dust removal process of iron ore sintering flue gas, and in the field of sintering flue gas treatment. It can solve the problems of low emission concentration, large sintering flue gas flow rate, Implementation and other issues to achieve the effect of improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

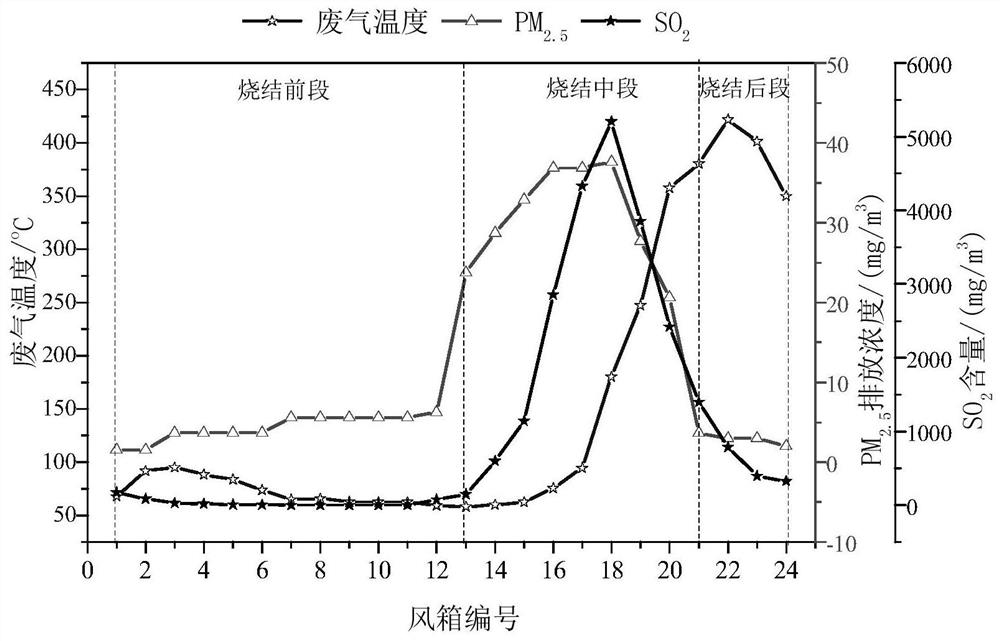

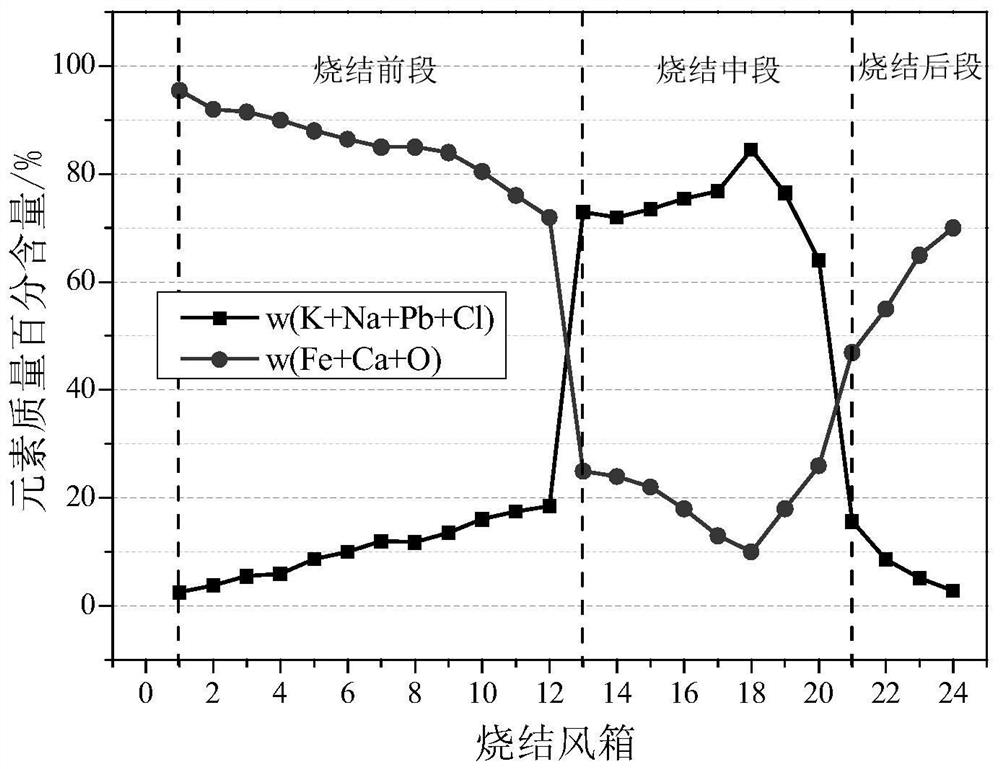

[0029] According to the PM emitted from flue gas in different wind boxes of sintering trolley 2.5 , SO 2 Emission concentration (see figure 1 ) and PM 2.5 chemical composition (see figure 2 ) change law, the sintering flue gas is divided into three sections, specifically: 1 # Bellows to 12 # The bellows is the front section of sintering, 13 # Bellows to 20 # The bellows is divided into a sintered middle section, 21 # Bellows to 24 # The bellows is the post-sintering section. Will 1 # -12 # The flue gas from the bellows is introduced into the low-temperature flue, and the 13 # -20 # The flue gas from the bellows is introduced into the medium temperature bellows; adjust 21 # -twenty four # The proportion of the high-temperature hot exhaust gas from the bellows entering the medium-temperature flue makes the flue gas temperature reach 180°C, and the rest of the high-temperature flue gas is introduced into the low-temperature flue to make its temperature higher than ...

Embodiment 2

[0031] According to the PM emitted from flue gas in different wind boxes of sintering trolley 2.5 , SO 2 Emission concentration (see figure 1 ) and PM 2.5 chemical composition (see figure 2 ) change law, the sintering flue gas is divided into three sections, specifically: 1 # Bellows to 12 # The bellows is the front section of sintering, 13 # Bellows to 20 # The bellows is divided into a sintered middle section, 21 # Bellows to 24 # The bellows is the post-sintering section. Will 1 # -12 # The flue gas from the bellows is introduced into the low-temperature flue, and the 13 # -20 # The flue gas from the bellows is introduced into the medium temperature bellows; adjust 21 # -twenty four # The proportion of the high-temperature hot exhaust gas from the bellows entering the medium-temperature flue makes the flue gas temperature reach 200°C, and the rest of the high-temperature flue gas is introduced into the low-temperature flue to make its temperature higher than ...

Embodiment 3

[0033] According to the PM emitted from flue gas in different wind boxes of sintering trolley 2.5 , SO 2 Emission concentration (see figure 1 ) and PM 2.5 chemical composition (see figure 2 ) change law, the sintering flue gas is divided into three sections, specifically: 1 # Bellows to 12 # The bellows is the front section of sintering, 13 # Bellows to 20 # The bellows is divided into a sintered middle section, 21 # Bellows to 24 # The bellows is the post-sintering section. Will 1 # -12 # The flue gas from the bellows is introduced into the low-temperature flue, and the 13 # -20 # The flue gas from the bellows is introduced into the medium temperature bellows; adjust 21 # -twenty four # The proportion of high-temperature hot exhaust gas from the bellows entering the medium-temperature flue makes the flue gas temperature reach 220°C, and the remaining high-temperature flue gas is introduced into the low-temperature flue to make its temperature higher than the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com