Method for determining content of bismuth in iron ores by hydride generation-atomic fluorescence spectrometry method

An atomic fluorescence spectrometry, hydride generation technology, applied in fluorescence/phosphorescence, material excitation analysis, etc., can solve the problems of using many reagents, long process, cumbersome operation process, etc., and achieve the effect of simple operation, great harm, and cumbersome operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

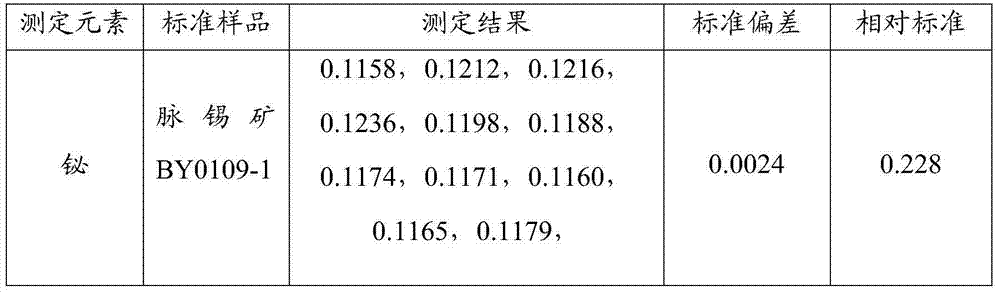

[0027] The general idea of the present invention is: melt and decompose the iron ore sample with sodium peroxide and sodium hydroxide, acidify it with dilute hydrochloric acid, then use ascorbic acid and thiourea to reduce the high-priced bismuth to low-priced bismuth, and at the same time mask the coexisting elements to eliminate the influence , to obtain the sample solution of iron ore; the sample solution is introduced into the atomic fluorescence photometer, and under the action of potassium borohydride, the bismuth is converted into bismuth hydrogen gas, which is sent to the quartz atomizer by the carrier gas, and then emitted after fully atomized The characteristic fluorescence spectrum is obtained, and the fluorescence measurement is carried out; the content of bismuth in the sample solution is obtained according to the fluorescence intensity measured by the bismuth standard solution of known concentration.

[0028] In the embodiments of the present invention, the reag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com