Cutting bed chip removal worktable

A technology of workbench and cutting equipment, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve problems affecting the health of processing personnel, destroying the working environment of processing workshops, environmental pollution, etc., and achieve high use and promotion Value, wide application range of equipment, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

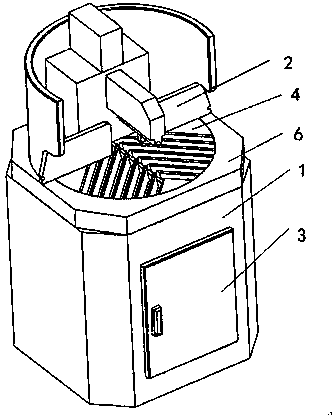

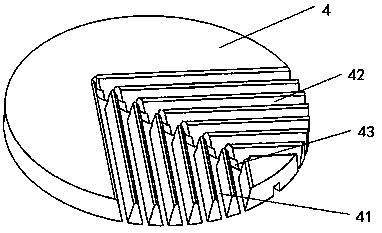

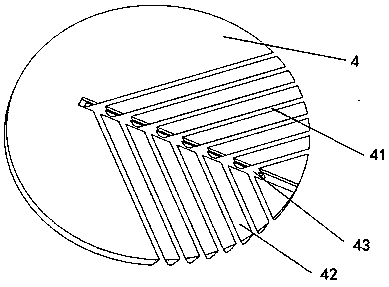

[0026] As shown in the figure, the present invention discloses a chip removal workbench for a cutting bed that can effectively complete waste discharge without changing the traditional cutting bed processing equipment.

[0027] Specifically, a chip removal workbench of a cutting bed is matched with the cutting bed processing equipment, and the cutting bed processing equipment includes an equipment support 1, a cutting equipment 2 fixedly arranged above the equipment support 1, and a cutting equipment 2 fixedly arranged on the The waste chip chamber 3 inside the equipment support 1 is characterized in that: the cutting bed chip removal workbench is arranged between the cutting equipment 2 and the equipment support 1, and the cutting bed chip removal workbench includes The pneumatic chip removal platform 6 that drives the movement of debris, the triangular chip collection platform 4 for waste collection, and the dragging chip cutting platform 5 for waste removal, the pneumatic ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com