UV-resistant IM coating material

A technology of coating materials and disappearing film, which is applied in the optical field, can solve the problems of difficult grinding of zirconia, low density of a single material, and high cost of nano-sized zirconia, so as to reduce the impact of images, improve light transmittance, The effect of high UV resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, objectives and effects of the invention easy to understand, the present invention is further described.

[0020] The following is a specific description of the UV-resistant film coating material provided in this case in conjunction with the examples as follows:

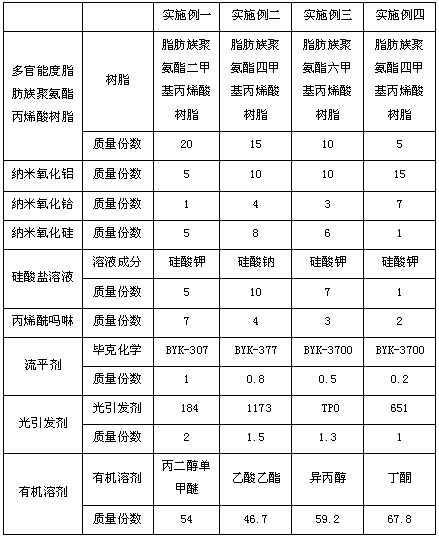

[0021] The following form is the mass part statistics of four kinds of embodiment components that the present invention exemplifies:

[0022]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com