Temperature-resistant composite cleaning fracturing fluid and preparation method thereof

A clean fracturing fluid and temperature-resistant technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of inability to degrade, fail to meet the field application promotion, and high cost, and achieve enhanced micellar network structure intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of the temperature-resistant composite clean fracturing fluid comprises the following steps:

[0031] (1) Disperse ordinary hydrophilic nano-silica in an organic solvent with an ultrasonic cleaner, then add acid anhydride organic matter, and stir magnetically at room temperature for 15 hours at a speed of 600-700 rpm to obtain acid anhydride-modified nano-silica. particle reaction solution.

[0032] (2) Put the anhydride-modified nanoparticle reaction solution obtained in step (1) into a high-speed centrifuge for high-speed centrifugation at a speed of 9000 rpm and a centrifugation time of 30 minutes. Collect the centrifuged product and wash it with ethanol for 3 times to remove untreated particles. After the fully reacted acid anhydride organic matter is washed with ethanol, it is vacuum-dried to remove the remaining organic solvent and ethanol, and the dried solid is ground to obtain the acid anhydride-modified nano-silica particles.

[0033] (...

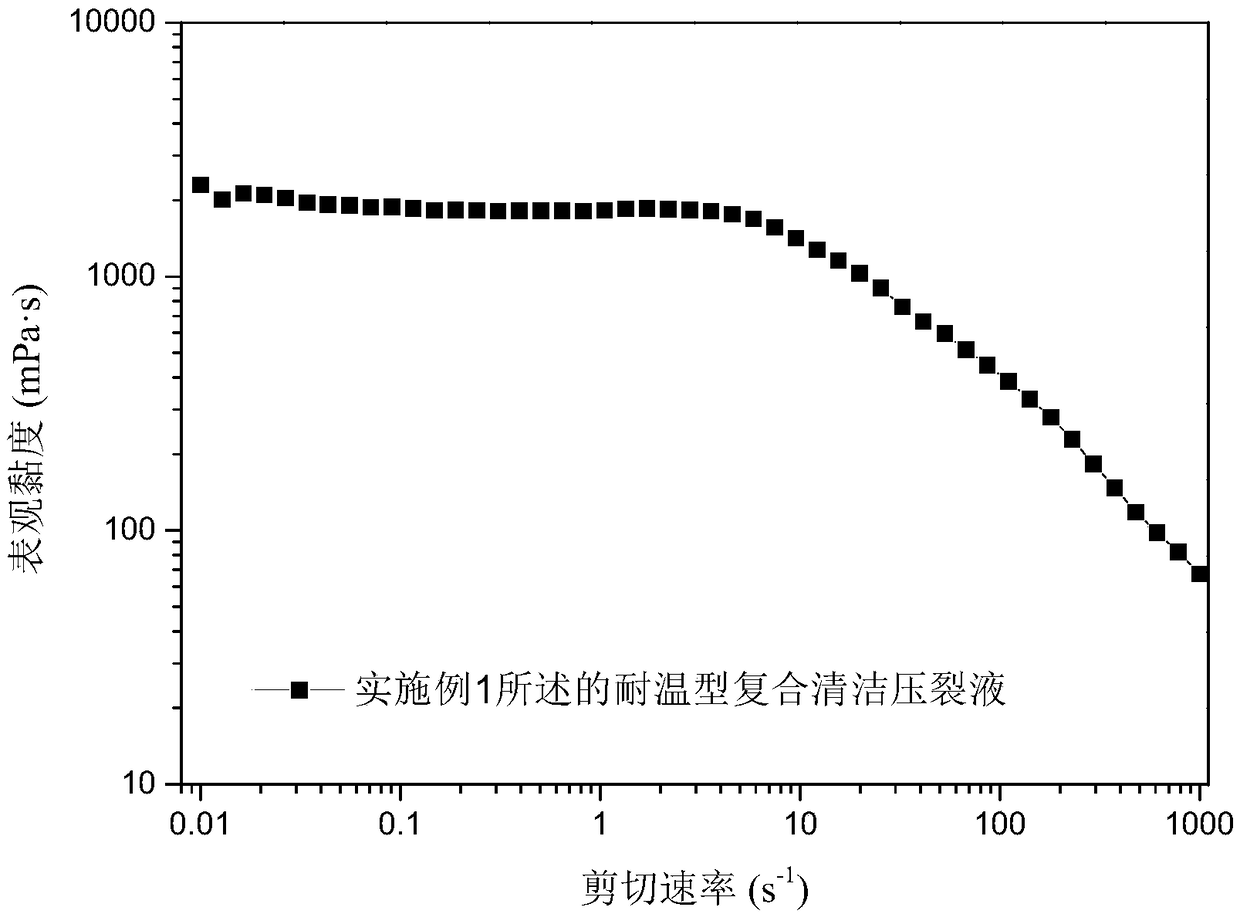

Embodiment 1

[0037] A temperature-resistant composite clean fracturing fluid, its components and mass percentages are as follows:

[0038]Behenamidopropyldimethylamine 1%; Sodium Salicylate 1%; Modified Nanoparticles 1% and the balance water.

[0039] The preparation method of the temperature-resistant composite clean fracturing fluid comprises the following steps:

[0040] (1) 2g particle size is 20nm, specific surface area 240m 2 / g of ordinary hydrophilic nano-silica is dispersed in 200ml of N,N-dimethylamide using an ultrasonic cleaner, then 2g of maleic anhydride is added, and magnetically stirred at room temperature for 15 hours at a speed of 600 rpm, that is The reaction solution of maleic anhydride modified nanoparticles was obtained.

[0041] (2) Put the maleic anhydride modified nanoparticle reaction liquid obtained in step (1) into a high-speed centrifuge and carry out high-speed centrifugation, the rotating speed is 9000 rpm, and the centrifugation time is 30 minutes; the cen...

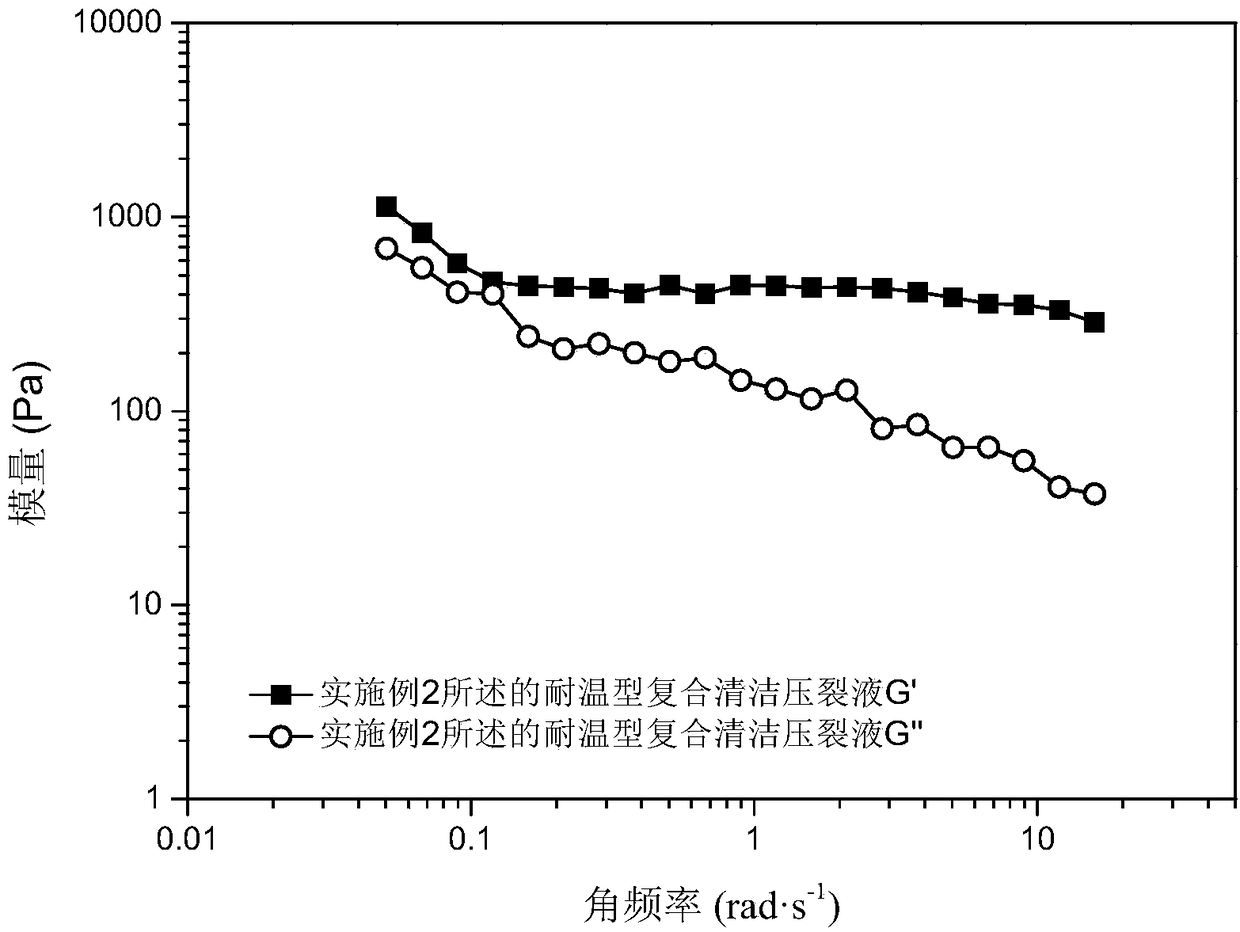

Embodiment 2

[0047] A temperature-resistant composite clean fracturing fluid, its components and mass percentages are as follows:

[0048] Stearic acid amidopropyl dimethylamine 2%; sodium p-toluenesulfonate 1.5%; modified nanoparticles 2% and the balance of water.

[0049] The preparation method of the temperature-resistant composite clean fracturing fluid comprises the following steps:

[0050] (1) 4g particle size is 25nm, specific surface area is 300m 2 / g of ordinary hydrophilic nano-silica is dispersed in 200ml of toluene with an ultrasonic cleaner, and then 4.5g of trimellitic anhydride is added, and magnetically stirred at room temperature for 15 hours at a speed of 650 rpm to obtain modified trimellitic anhydride. Nanoparticle reaction solution.

[0051] (2) Put the trimellitic anhydride modified nano-particle reaction solution obtained in step (1) into a high-speed centrifuge for high-speed centrifugation, the rotating speed is 9000 rpm, and the centrifugation time is 30 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com