Modified cathode active material, preparation method of modified cathode active material and lithium secondary battery

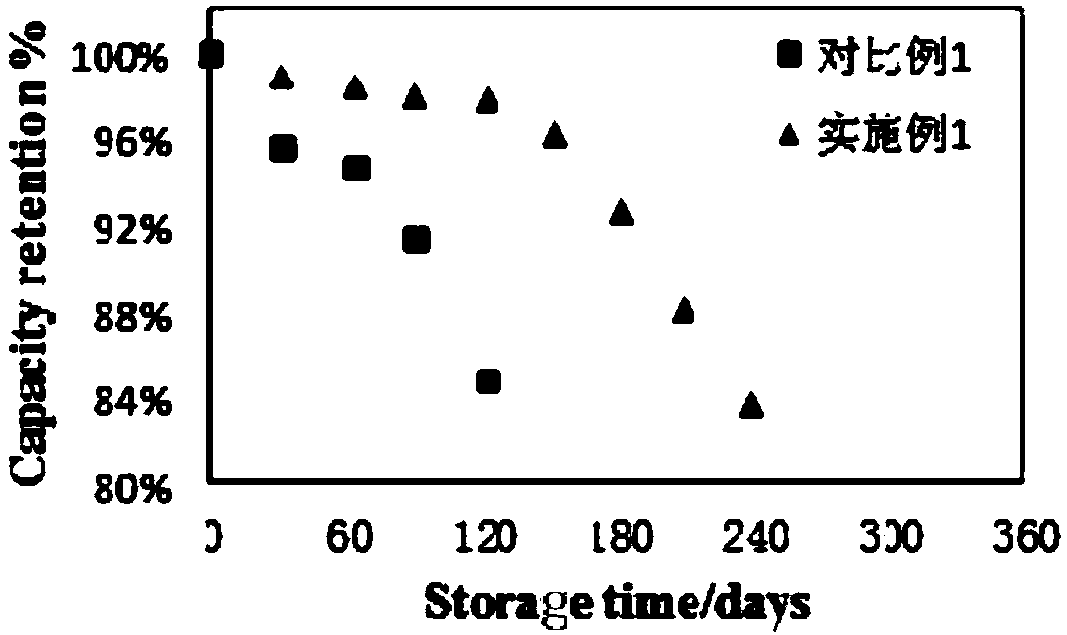

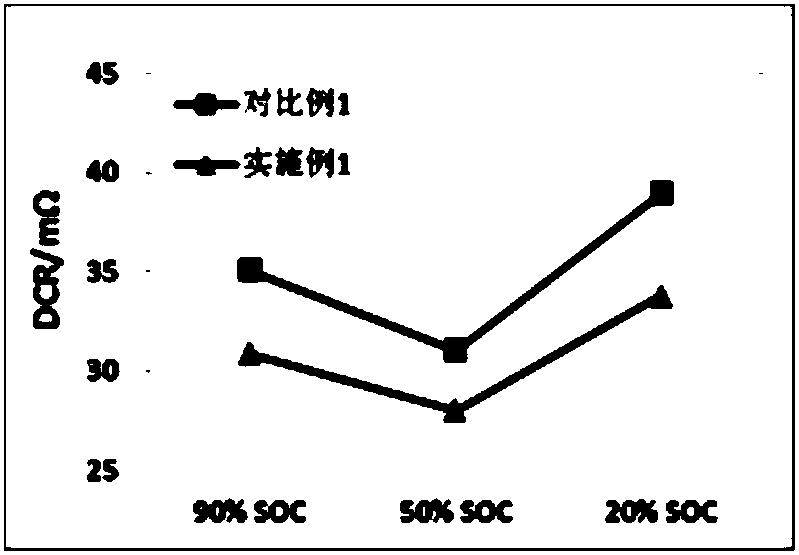

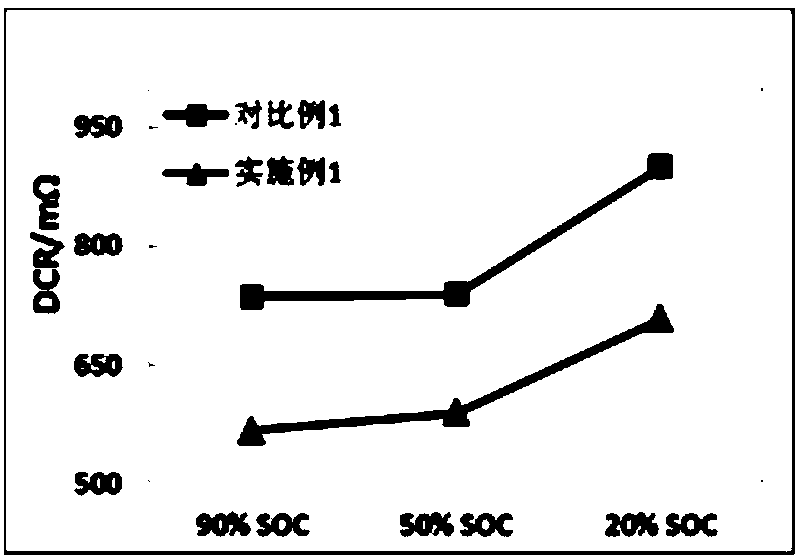

A positive electrode active material and a positive electrode active material technology are applied in the field of lithium secondary batteries, modified positive electrode active materials and their preparation, which can solve the problem of not having electronic conductivity and ionic conductivity, and reducing the kinetic performance of lithium ion secondary batteries. , increase the overall impedance of lithium-ion secondary batteries, etc., to achieve the effect of improving dynamic performance, improving cycle and storage life, and reducing impedance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] Next, illustrate the preparation method of the modified positive electrode active material according to the second aspect of the present invention, which is used to prepare the modified positive electrode active material according to the first aspect of the present invention, comprising the steps of: (1) combining the oxide with the positive electrode active material After mixing and sintering, a positive electrode active material coated with an oxide is obtained, wherein the general formula of the oxide is N x o y , N is selected from one or more of transition metal elements and elements of the third main group, 1 / 4≤y / x≤4; (2) combining the positive electrode active material coated with oxide with the perovskite structure The lanthanum strontium manganese oxide compound is mixed and sintered, so that the lanthanum strontium manganese oxide compound is coated on the surface of the oxide, and the modified positive electrode active material is obtained.

[0026] In the p...

Embodiment 1

[0038] (1) Preparation of modified cathode active materials

[0039] La(NO 3 ) 3 , Sr(NO 3 ) 2 , Mn(NO 3 ) 2 Mix according to the material ratio of 7:3:10, add to deionized water and mix evenly to prepare a nitrate solution with a total concentration of La, Sr, and Mn metal ions of 0.5mol / L. Adding citric acid as a complexing agent, the mass ratio of citric acid and nitrate is 1-2, and then stirring evenly. Add dilute ammonia water to adjust the pH of the solution, and control the pH at about 2.5. Ethylene glycol was added under stirring to carry out solization reaction, and the amount of ethylene glycol was controlled to be the same as that of citric acid, and then the solution was heated to 80° C. for gelation treatment to obtain a wet gel. Dry the wet gel at a constant temperature of 120° C. for 24 hours to dehydrate to prepare a xerogel. Then the obtained xerogel was subjected to self-propagating sintering reaction at 300°C for 1 h to obtain La 0.7 Sr 0.3 MnO 3 ...

Embodiment 2

[0048] Lithium-ion secondary batteries were prepared according to the method of Example 1, the difference being:

[0049] (1) Preparation of modified cathode active materials

[0050] La 0.7 Sr 0.3 MnO 3 The synthesis is the same as in Example 1.

[0051] ZrO 2 and positive active material LiNi 0.5 co 0.25 mn 0.25 o 2 Mixed according to the mass ratio of 0.1:100, and then sintered at 600 ° C for 6 hours to obtain the coated ZrO 2 positive electrode active material; the above material and La 0.7 Sr 0.3 MnO 3 Mix in solid phase at a mass ratio of 100:0.3, sieve, and then perform solid phase sintering at 600° C. to 650° C. for 8 hours to obtain the modified positive electrode active material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com