Composite lithium manganese silicate cathode material and preparation method thereof

A positive electrode material, lithium manganese silicate technology, applied in the field of positive electrode materials for lithium-ion batteries, can solve the problems of low electronic conductivity, poor structural stability, poor electrochemical performance, etc., and achieve uniform microscopic appearance and good electrochemical performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

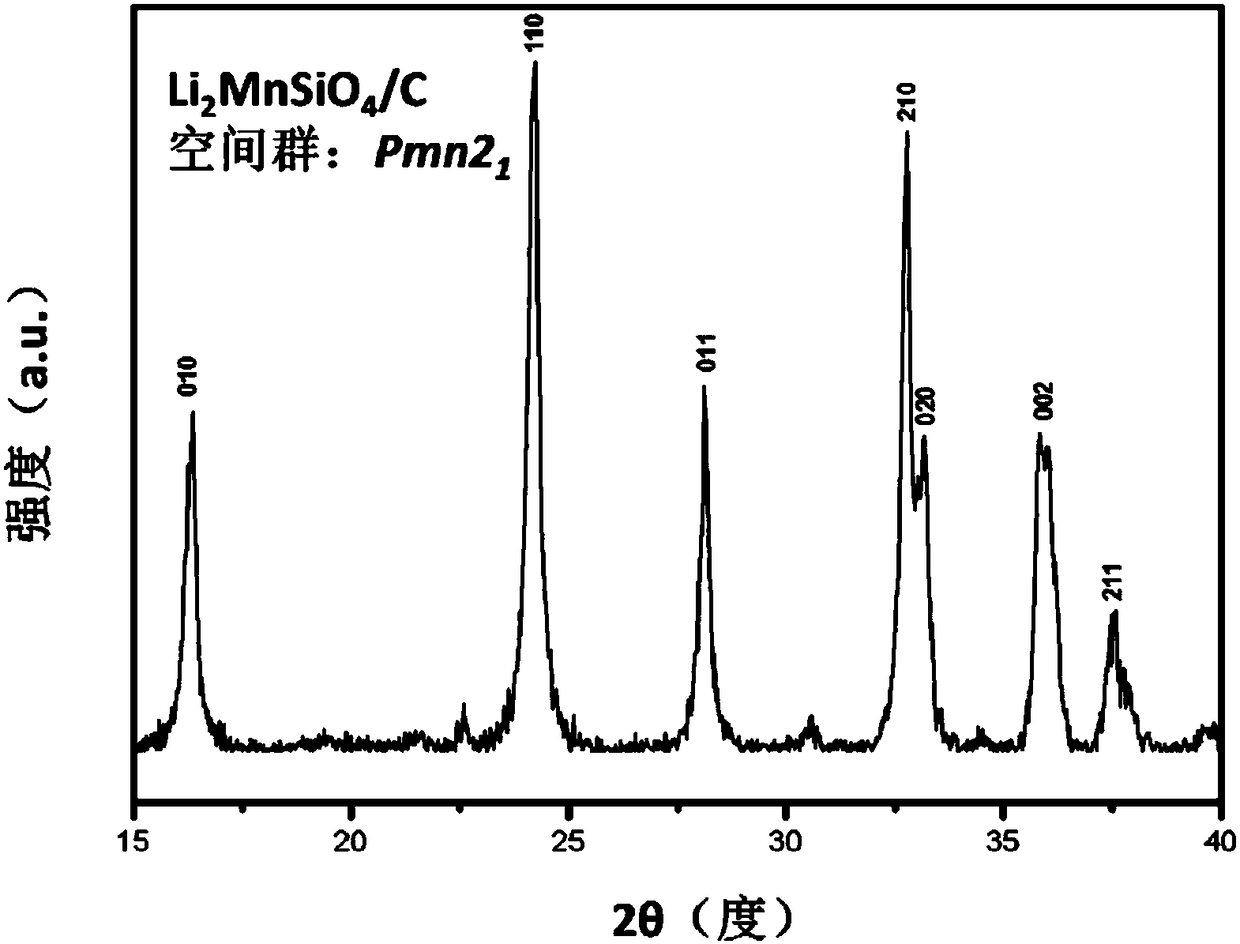

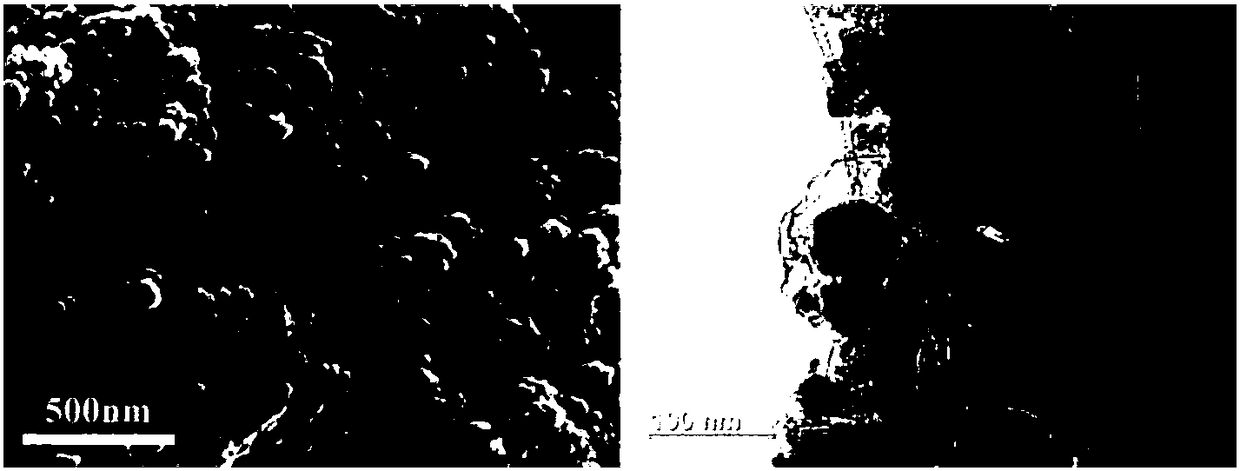

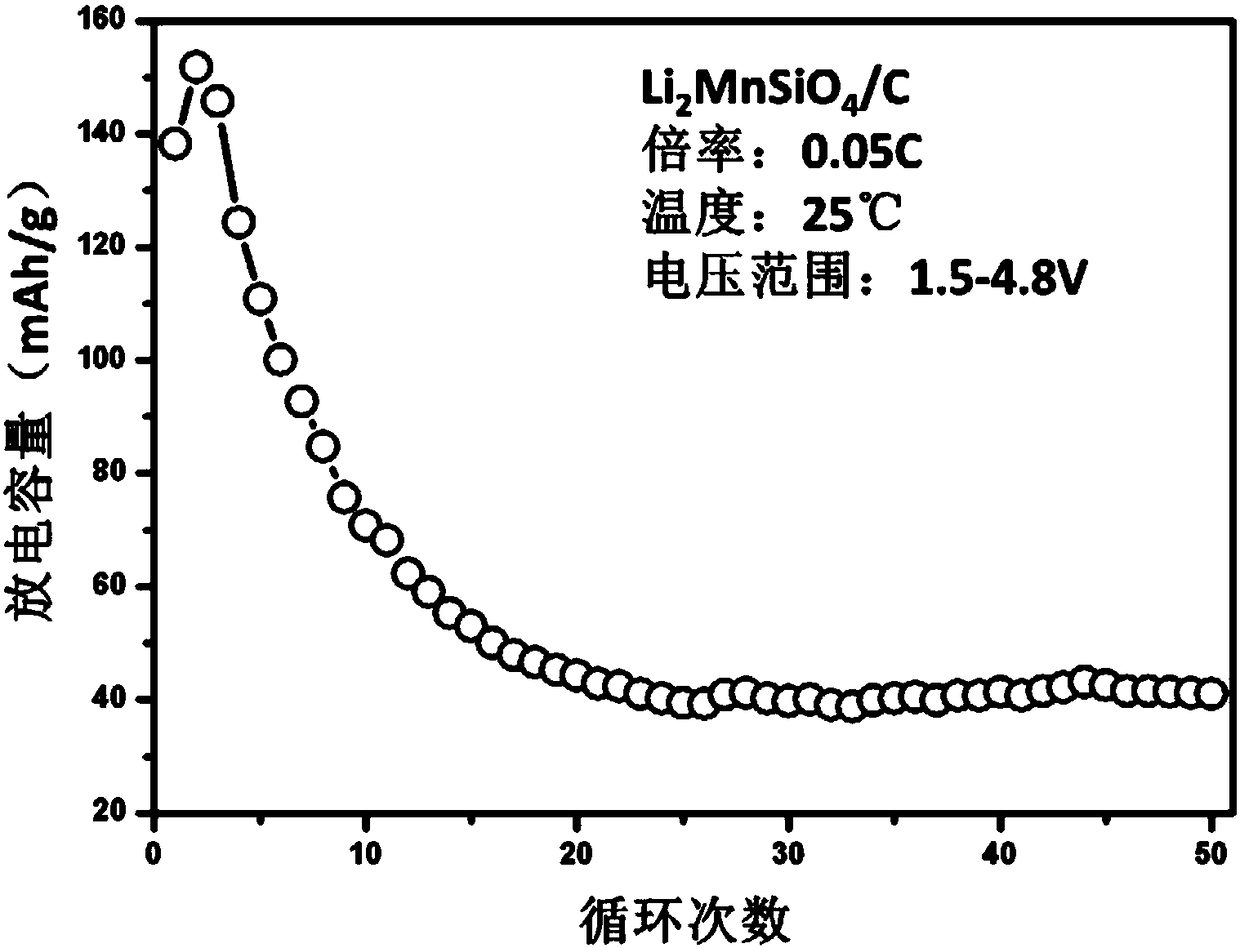

[0033] In one embodiment, a method for preparing a composite lithium manganese silicate positive electrode material, comprising: uniformly mixing reactants other than lithium sources and carbon sources, and performing the first step of carbon coating by hydrothermal reaction to prepare precursors After the hydrothermal reaction, the carbon source is used to carry out the second step of carbon coating on the precursor to obtain an intermediate product; the intermediate product after the second step of carbon coating is mixed with lithium (such as ball milling mixed with lithium), and heat treated A final product is obtained; wherein the reactants other than the lithium source include a manganese source and a silicon source. By introducing two-step carbon coating and doping with equivalent metal ions, Pmn2 uniformly coated with amorphous carbon layer and doped with a small amount of equivalent metal ions is obtained. 1 Orthorhombic lithium manganese silicate nanoparticles have u...

example 1

[0045] Measure and mix absolute ethanol and water with a volume ratio of 5:1, add an appropriate amount of ammonia water to adjust the pH value, add an appropriate amount of starch (10% of the mass of the base material), and add according to the molar ratio of manganese and silicon elements of 1.0:1.0 Manganese acetate and tetraethyl orthosilicate, continuously magnetically stirred for 4 hours until the solution is fully hydrolyzed and mixed evenly. At this time, the mixed solution is dark black. Put it in a hydrothermal reaction kettle and react at 150°C for 24 hours. The second step Carbon coating Ultrasonic dispersion of the hydrothermal precursor, and uniformly added to the fully gelatinized starch sol (20% of the mass of the matrix material), in a water bath at 70 ° C for 4 hours and magnetic stirring until fully mixed, and then the coated Add an appropriate amount of lithium carbonate to the precursor, ball mill for 10 hours at a speed of 450 rpm, and finally dry the mixt...

example 2

[0050] Measure and mix absolute ethanol and water with a volume ratio of 5:1, add an appropriate amount of ammonia water to adjust the pH value, add an appropriate amount of starch (15% of the mass of the base material), and adjust the molar ratio of manganese, silicon, and nickel to 0.95 :1.00:0.05 Add manganese acetate, ethyl orthosilicate, nickel acetate, and continue magnetic stirring for 4 hours until the solution is fully hydrolyzed and mixed evenly. At this time, the mixed solution is dark black. Place it in a hydrothermal reaction kettle at 150°C The second step of carbon coating is to ultrasonically disperse the hydrothermal precursor, and evenly add it to the fully gelatinized starch sol (15% of the mass of the matrix material), and place it in a water bath at 80°C for 2 hours and magnetically stir until fully Mix, then add an appropriate amount of lithium acetate to the coated precursor, ball mill for 8 hours at a speed of 400 rpm, and finally dry the mixture, and ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com