A sulfuric acid dechlorination system for waste lead-acid batteries and its dechlorination method

A lead-acid battery, sulfuric acid technology, applied in the direction of lead-acid battery, battery recycling, recycling technology, etc., can solve the problems of high cost of electrodialysis, poor operability, and impurities brought in, to meet the requirements of chlorine content and improve service life , good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

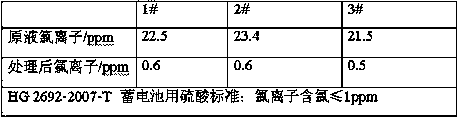

Examples

Embodiment Construction

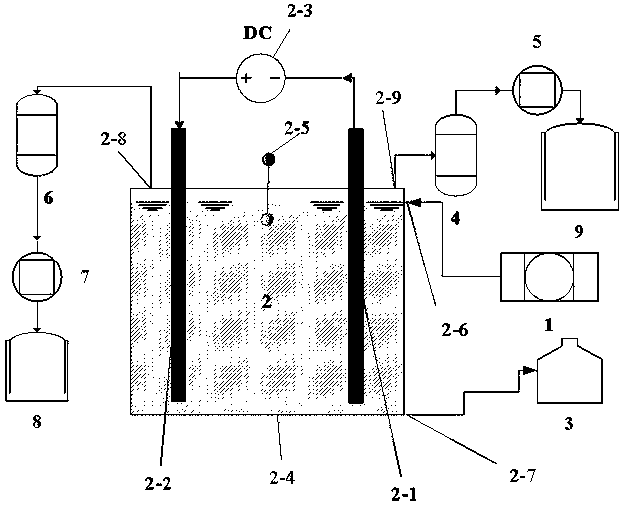

[0026] Such as figure 1 As shown, the present invention provides a sulfuric acid dechlorination system for waste lead-acid batteries, which includes a filter 1, a dechlorination device 2 and an acid storage tank 3 which are sequentially connected through an infusion pipeline. Wherein, the dechlorination device 2 includes an electrolytic cell 2-4, a cathode electrode 2-1, an anode electrode 2-2, an electrolysis power supply 2-3 and a gas separator 2-5. The electrolytic cell 2-4 is or is lined with pp plastic steel container, and is a closed cell body. The filter 1 is connected with the acid inlet 2-6 on the top of the electrolytic cell 2-4 with a pipeline, and the acid storage tank 3 is connected with the acid outlet 2-7 at the bottom of the electrolytic cell 2-4 with a pipeline. The filter 1 is a plate and frame filter press equipment, which also includes filtrate testing equipment. The gas separator 2-5 is arranged between the cathode electrode 2-1 and the anode electrode 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com