Preparation method and application of magnetic nano iron-manganese double metal oxide composite catalyst

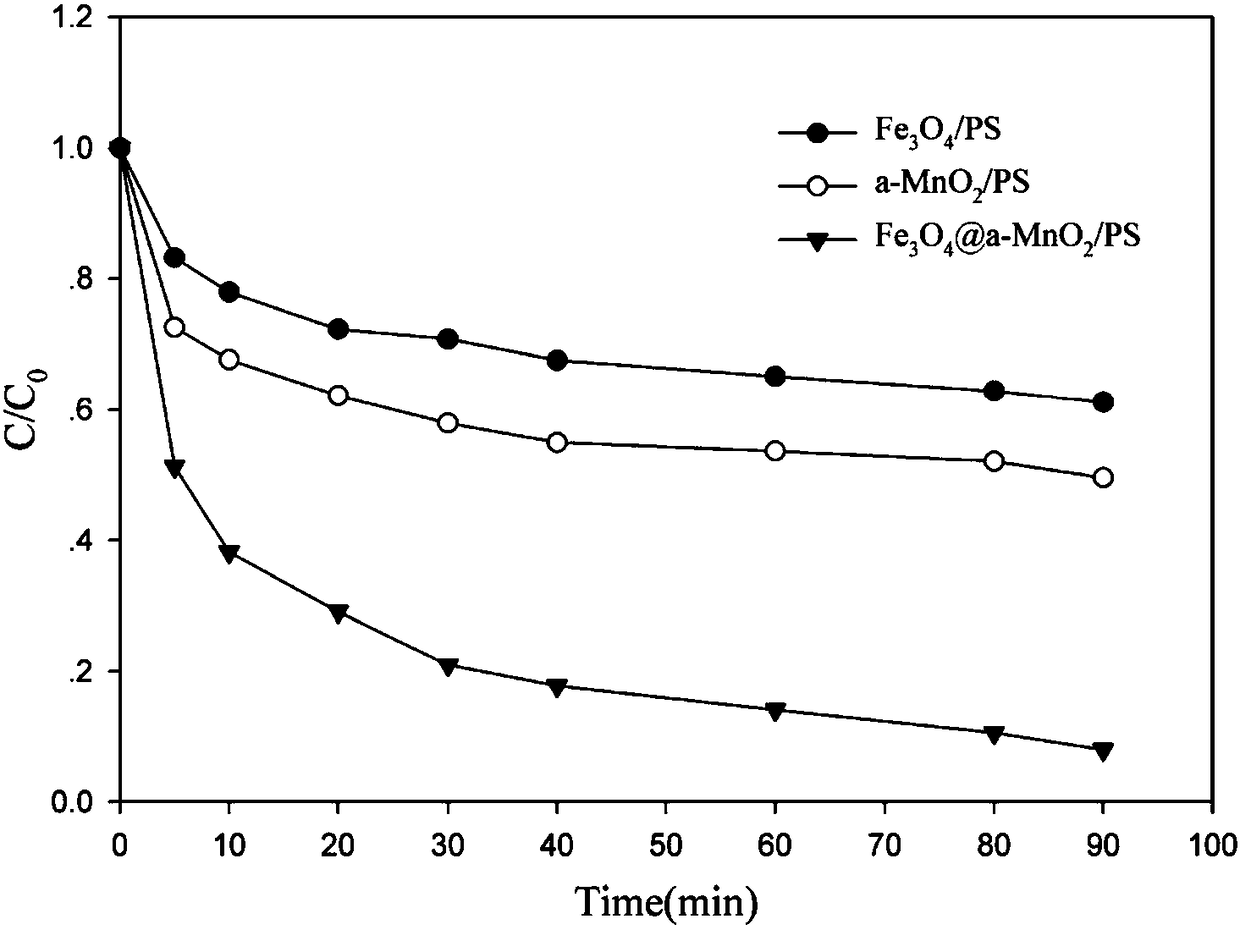

A double metal oxide, composite catalyst technology, applied in metal/metal oxide/metal hydroxide catalyst, catalyst activation/preparation, physical/chemical process catalyst, etc., can solve the problem of unsatisfactory catalytic effect and poor catalytic effect. Ideal, secondary pollution and other problems, to reduce secondary pollution, overcome the difficulty of difficult recovery, and achieve the effect of less dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Dissolve ferrous sulfate heptahydrate and polyvinylpyrrolidone in deionized water at a mass ratio of 2.78 to 3:1, and stir quickly and evenly.

[0034] (2) Stir the material obtained in step (1) magnetically in an oil bath at 70-85°C, quickly add NaOH solution to make the molar ratio of ferrous sulfate to 2-3:1, seal the reaction for 2-3 hours, and black The precipitate was dried under vacuum at 65°C to obtain Fe 3 o 4 .

[0035] (3) Fe obtained by step (2)3 o 4 Grinding into powder, then dissolving the powder and potassium permanganate in deionized water at a mass ratio of 4:5-6, ultrasonically mixing for 5-10 minutes, and then adding 0.7-2.0 mL of dilute hydrochloric acid dropwise to shake well.

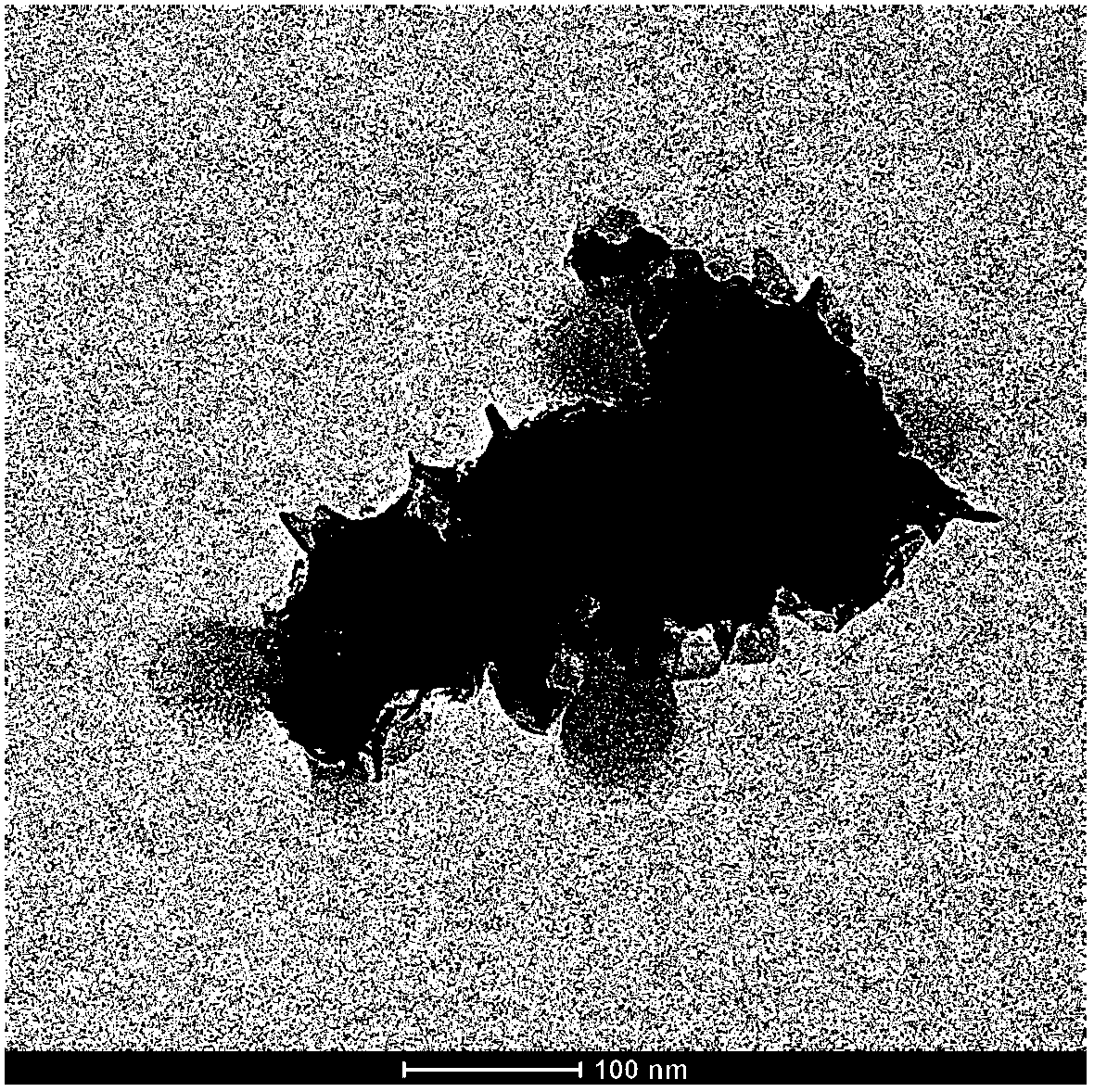

[0036] (4) Transfer the material obtained in step (3) into a high-pressure reactor, heat and react at 100-120°C for 10-12 hours, then cool to room temperature, then wash with deionized water until the supernatant is neutral, and dry under vacuum Obtain the magnetic n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com