Coating machine head sieving device

A machine head and coating technology, which is applied to the device, coating, filtration and separation of the surface coating liquid, etc., can solve the problems of poor operability, instability, complex equipment structure, etc., to improve the material loss and time consumption problems , The effect of improving the consistency of coating thickness and high stability of electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation, structure, features and functions of the coating head screening device according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

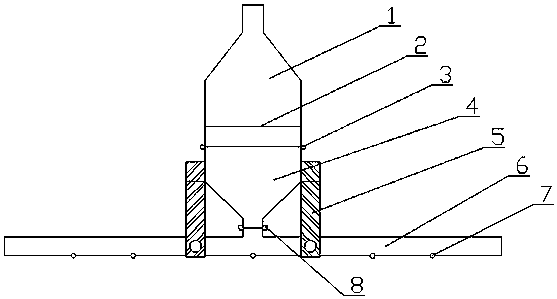

[0016] see figure 1 , the sieving device of the coating machine head of the present invention comprises an upper funnel 1, a lower funnel 4, and a flow divider 6, wherein: the upper funnel 1 and the lower funnel 4 are connected in a snap-fit type, and the bottom of the upper funnel 1 is equipped with a screen 2 , The lower funnel 4 is fixed in the fixed bracket 5, the bottom of the lower funnel 4 is connected with a flow divider 6, and the bottom of the flow divider 6 is provided with a plurality of flow holes 7. The upper funnel 1 and the lower funnel 4 are symmetrically connected through the connecting ring A3. The lower funnel 4 and the flow divider 6 are connected through a connecting ring B8. The outer periphery of the sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com