Online tool abrasion detection device based on CCD and detection method of online tool abrasion detection device

A detection device and tool technology, applied in manufacturing tools, measuring/indicating equipment, metal processing equipment, etc., can solve problems such as affecting workpiece processing quality, tool waste, and increasing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

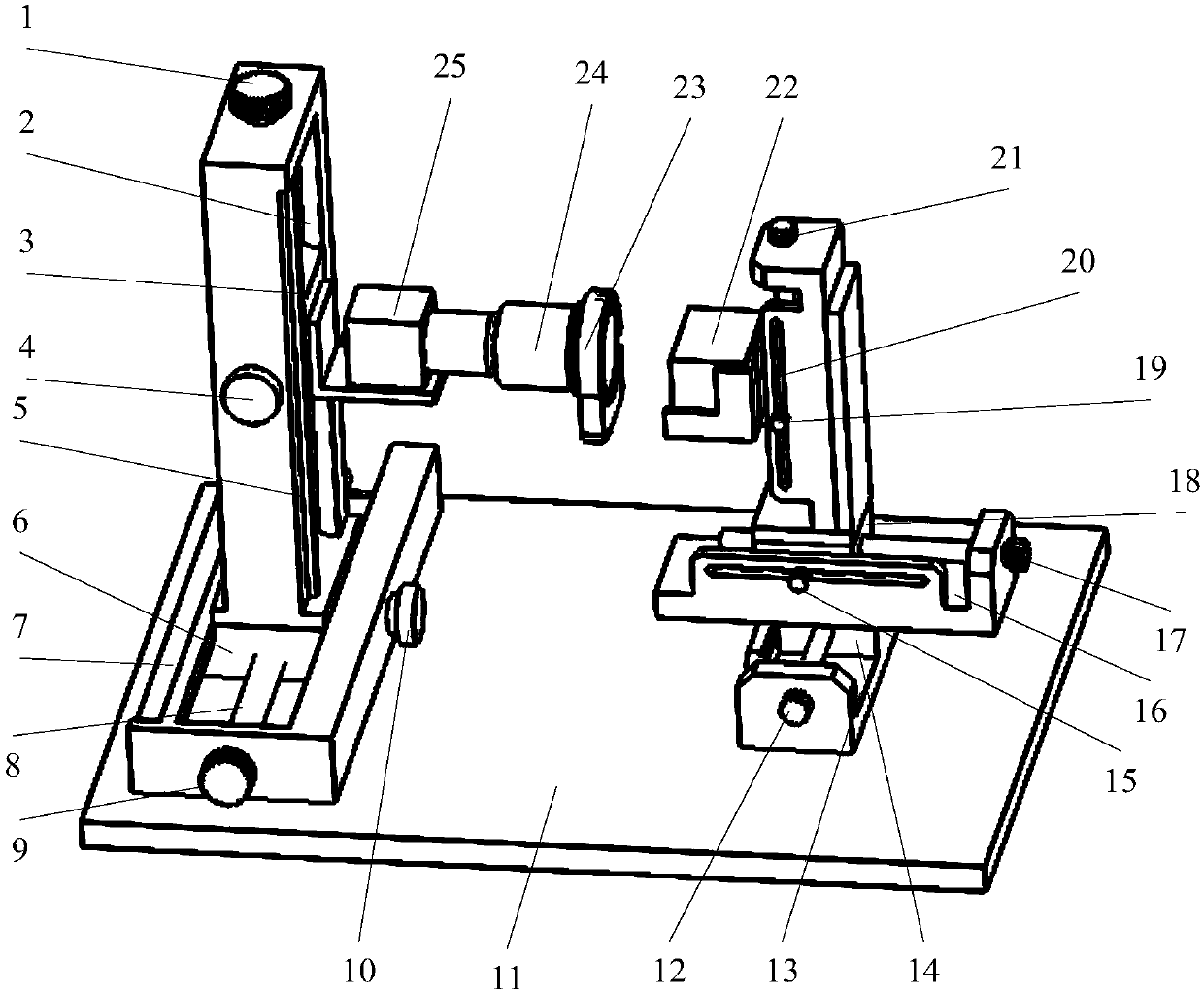

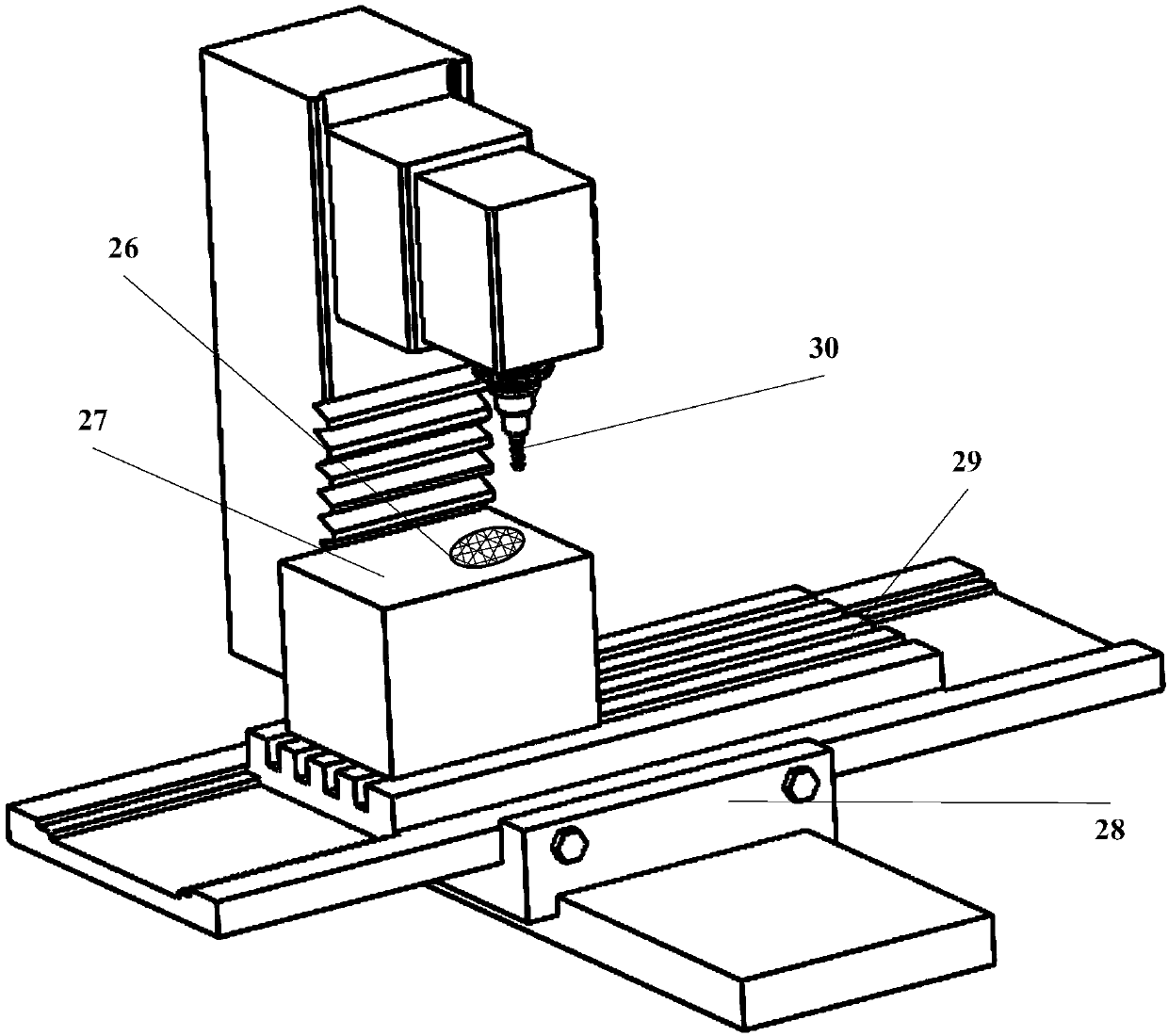

[0054] Such as figure 1 As shown, the online detection device for tool wear and damage based on CCD of the present invention includes a collection box 27, an industrial computer (not shown in the figure) and a display (not shown in the figure). Mainly be provided with CCD industrial camera 25, bi-telecentric lens 24, annular light source 23, prism 22 in collecting box 27, CCD industrial camera 25, bi-telecentric lens 24, industrial computer and display are connected successively.

[0055] The collection box 27 is formed by setting a box body on the base 11. The box body includes four side box doors and a top box door. Each door can be opened. Brush mouth 26. The base 11 of the collection box 27 is provided with a camera lateral movement mechanism and a prism Y direction movement mechanism, the camera transverse movement mechanism is provided with a camera longitudinal movement mechanism, and the CCD industrial camera 25 is installed on the longitudinal slider 3 of the camera ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com