Heatproof ABS resin and preparation method thereof

An ABS resin, heat-resistant technology, applied in the field of polymer material preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0023] This example proposes a method for preparing heat-resistant ABS resin, which is based on the process of synthesizing ABS resin by continuous bulk method.

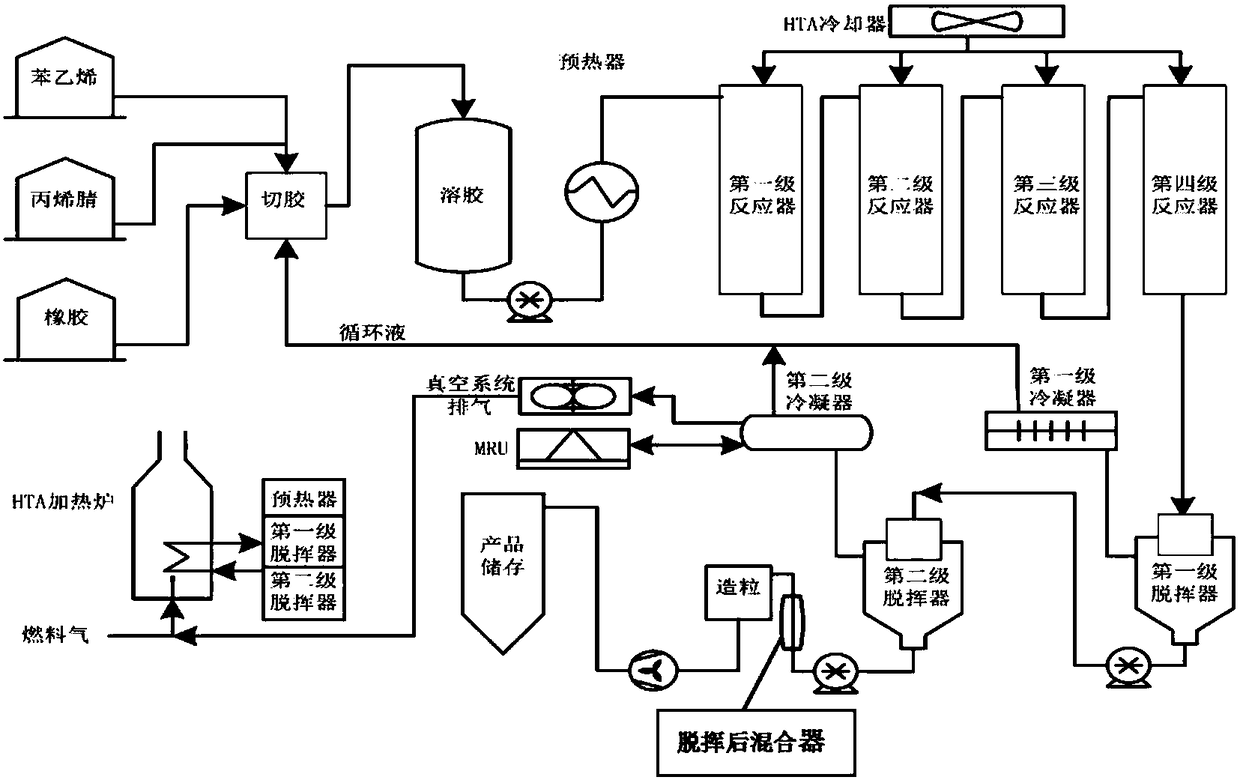

[0024] The technological process and unit settings of ABS resin synthesis by continuous bulk method, such as figure 1 shown. Among them, the main units include: raw material unit, additive unit, sol unit, polymerization reaction unit, devolatilization unit and granulation unit; subsidiary units include circulating liquid unit, refrigeration unit, utility system and heat transfer oil system. The functions of each main unit are as follows:

[0025] 1. Raw material unit: Styrene, acrylonitrile and rubber are provided.

[0026] 2. Additive unit: provide corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com