Production technology of oil-proof fabric

A manufacturing process and manufacturing process technology, which is applied in the field of oil-repellent fabric manufacturing process, can solve the problems such as poor oil-repellent effect, and achieve the effect of convenient cleaning and convenient fixed support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

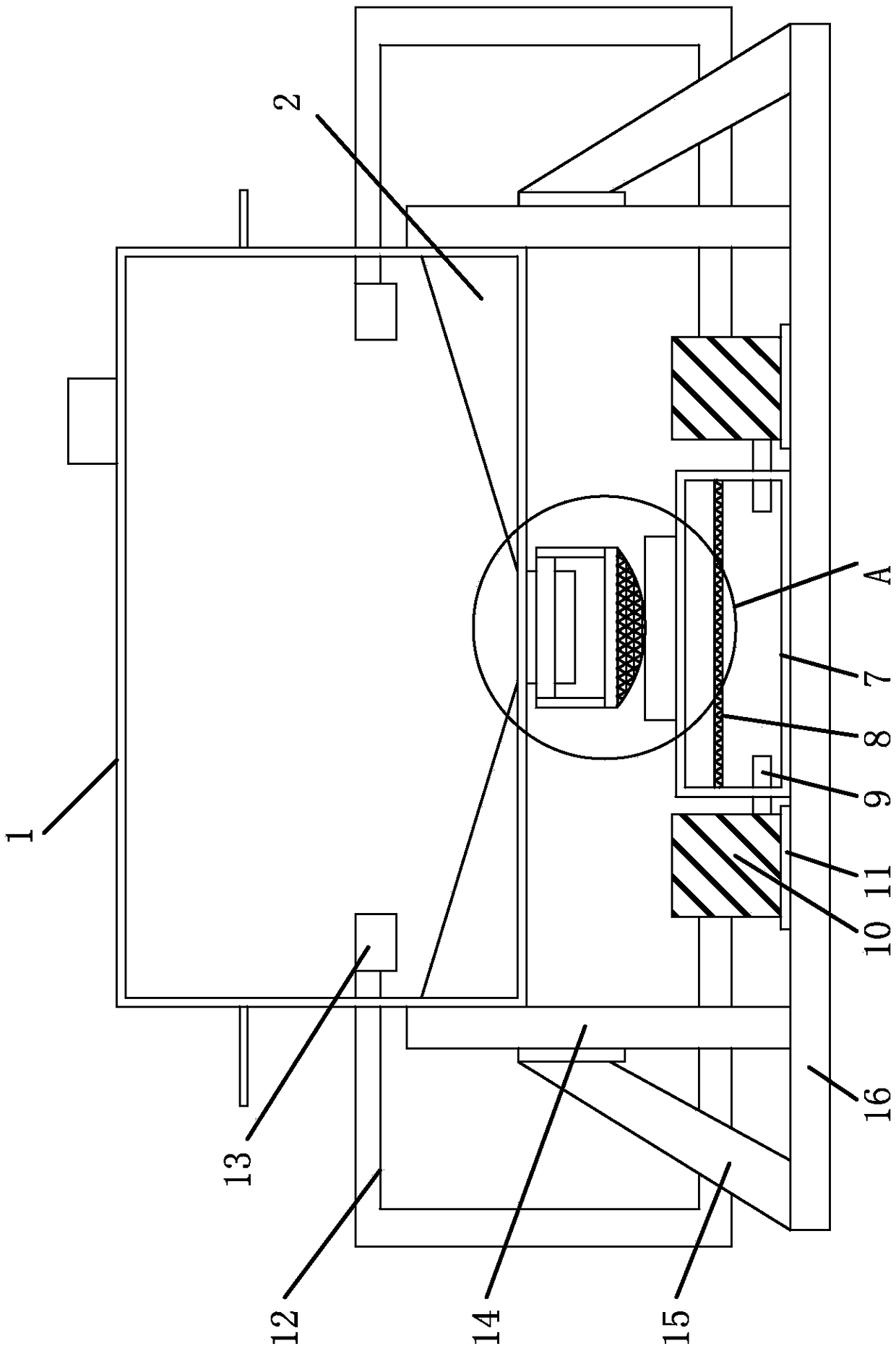

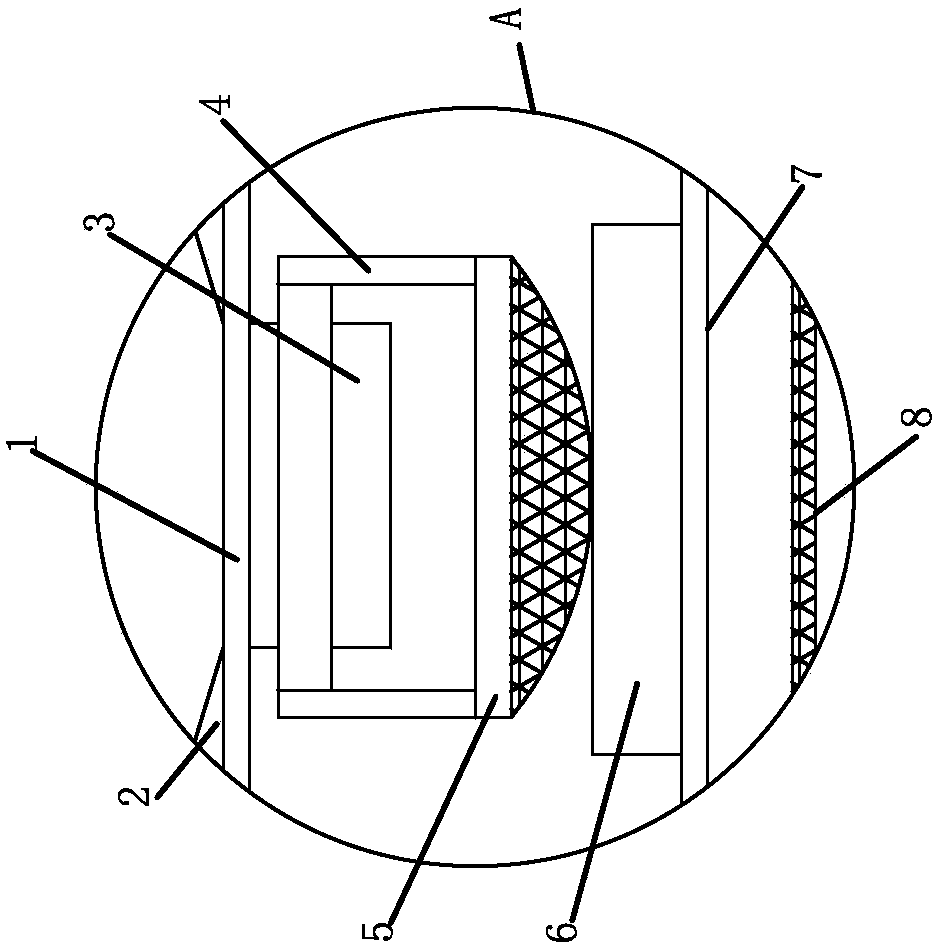

[0028] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

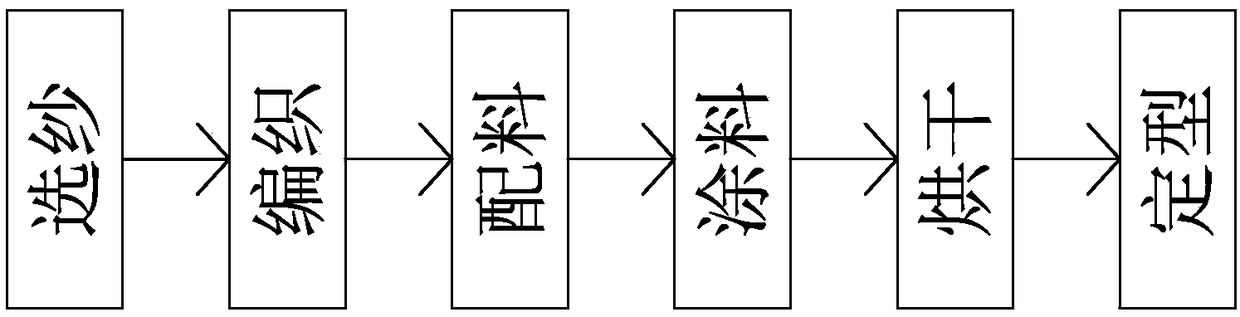

[0029] Such as figure 1 Shown, a kind of manufacture craft of oil-proof fabric, this manufacture craft comprises the following steps:

[0030] a. Yarn selection: elastic fibers are used as warp threads, and spandex fibers are used as weft threads;

[0031] b. Weaving: knitting the warp and weft into the base fabric through the knitting machine;

[0032] c. Ingredients: 6-7 parts of polyether ether ketone, 31-35 parts of amphiphilic polyurethane;

[0033] 20-25 parts of fluoroalkyl acrylate copolymer and 5-8 parts of polyvinylidene chloride are placed in the batching bucket and mixed to form a coating;

[0034] d. Coating: apply the coating on the base fabric through a coating machine, and the ratio of the thickness of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com