Fixing device and construction method for controlling floating of shield tunnel segments

A shield tunnel segment and fixing device technology, which is applied in the direction of tunnels, tunnel linings, shaft equipment, etc., can solve the problems of long construction period, short construction period, and low cost, so as to reduce the amount of engineering, improve construction efficiency, and save construction costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

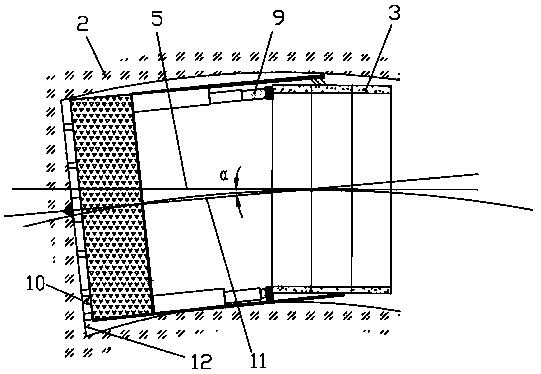

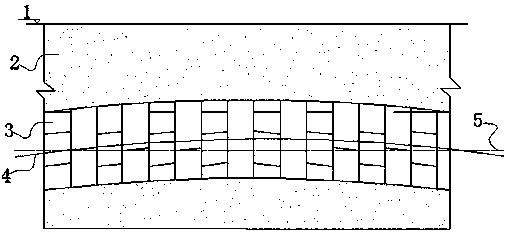

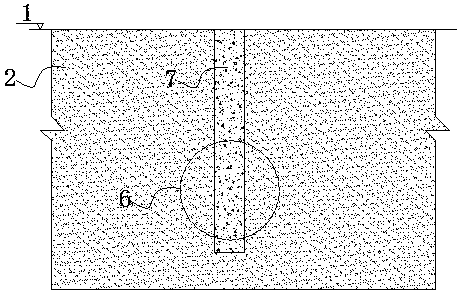

[0056] Such as Figure 3 ~ Figure 6 As shown, the fixing device used to control the floating of the shield tunnel segment includes a plurality of anti-floating piles 7 arranged in sequence along the route direction of the shield tunnel, and each of the anti-floating piles 7 moves from the top of the tunnel to the One side extends, so that the shield tunnel segment 3 is constrained under the anti-floating pile 7 after installation.

[0057] By setting the anti-floating pile 7 on the route of the shield tunnel, after the shield tunnel passes through the anti-floating pile 7, the distance between the shield tunnel segment 3 and the anti-floating pile 7 is only between the outer diameter of the shield machine and the outer diameter of the segment The distance between the gaps, when the segment comes out of the tail of the shield and before the grout has solidified, the anti-floating pile 7 has a restraining effect on the floating of the segment, and the friction between the anti-f...

Embodiment 2

[0067] The construction method of controlling the floating of the shield tunnel segment, when using the fixing device for controlling the floating of the shield tunnel segment as in embodiment 1 to limit the floating of the segment, proceed according to the following steps:

[0068] a, determine the burial depth of the anti-floating pile 7 and the spacing between each anti-floating pile 7;

[0069] b, making anti-floating pile 7;

[0070] c, make crown beam 8, described crown beam 8 connects each anti-floating pile 7, forms integral anti-floating structure;

[0071] d. The shield tunneling machine passes through the anti-floating piles 7, so that the shield tunnel segments 3 are constrained under the anti-floating piles 7.

[0072] In this embodiment, three anti-floating piles are set, and one crown beam is set. In specific applications, the number of anti-floating piles and crown beams is determined according to the distribution characteristics of engineering mudstone.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com