Tunnel secondary lining trolley hydraulic end die and construction method thereof

A secondary lining, hydraulic end technology, applied in tunnel lining, tunnel, shaft lining and other directions, can solve the problems of affecting the construction period, high construction cost, low construction efficiency, etc., to improve labor productivity, save manpower and material resources, and reduce construction costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

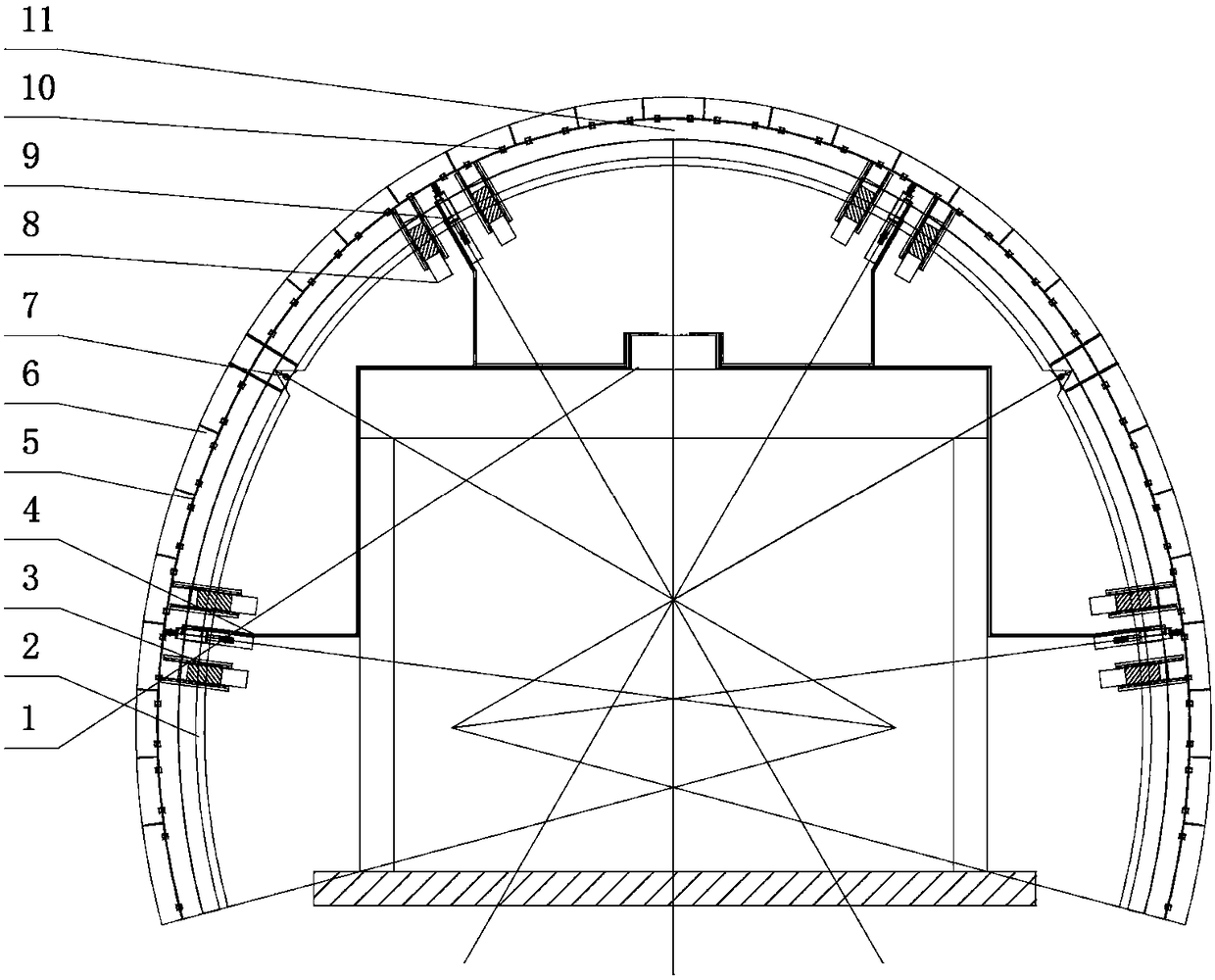

[0013] A hydraulic end die of a tunnel secondary lining trolley, such as figure 1 As shown, it includes: hydraulic control system 1, trolley side mold assembly 2, trolley side mold end head mold fixing device (ie guide groove) 3, trolley side mold end head mold hydraulic expansion device 4, ring-shaped middle stop Water hose 5, trolley side mold end mold assembly 6, trolley end mold connecting device 7, trolley top mold end mold fixing device (ie guide groove) 8, trolley top mold end mold hydraulic expansion device 9. Trolley top die end die assembly 10, trolley top die assembly 11.

[0014] Side mold end mold part:

[0015] The trolley side mold assembly 2 is fixed with the trolley side mold end mold assembly 6 through the trolley side mold end die fixing device (i.e. guide groove), and the trolley side die end head mold hydraulic expansion device 4 is connected with the platform The car side die end die assembly 6 is connected. Among them, the hydraulic control system 1 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com