Method for quickly synthesizing load type metal nano-particle

A technology of metal nanoparticles and synthetic loading, applied in the direction of non-metal elements, chemical instruments and methods, silicon compounds, etc., can solve the problems of catalyst blockage, reduce catalyst activity, time-consuming and other problems, and achieve the effect of inhibiting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

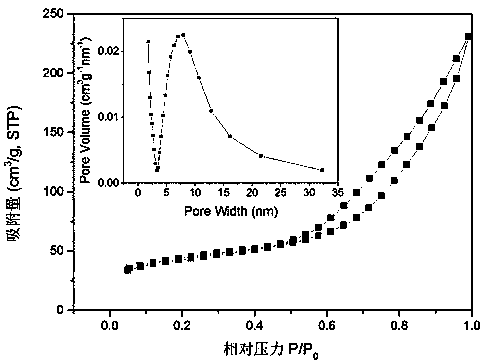

[0016] Add 1.2g of P123 into the dilute hydrochloric acid solution, stir until completely dissolved, then add 1.2g of n-butanol, stir in a constant temperature water bath at 35 ºC for 1 h, then add 2.58g of ethyl orthosilicate, and continue stirring for 24h, To obtain the mixed solution A, transfer the mixed solution A to a polytetrafluoroethylene reaction kettle, heat it in an oven at 100°C for 24 hours, after the reaction is completed and cool to room temperature, centrifuge the mixed solution to obtain a white product, and the product is obtained at 100°C Dry, wash the dried product with hydrochloric acid-ethanol mixed solution until neutral, then place the washed solid in a muffle furnace, raise the temperature to 550 ºC at a heating rate of 1 ºC / min, and keep it for 6 h , to prepare mesoporous silica material.

[0017] The mesoporous silica is baked in an oven to remove impurities adsorbed in the pores of the molecular sieve. A certain amount of 1-hexanol and chloroauric...

Embodiment 2

[0019] Add 1.2g of P123 into the dilute hydrochloric acid solution, stir until completely dissolved, then add 1.2g of n-butanol, stir in a constant temperature water bath at 35 ºC for 1 h, then add 2.58g of ethyl orthosilicate, and continue stirring for 24h, To obtain the mixed solution A, transfer the mixed solution A to a polytetrafluoroethylene reaction kettle, heat it in an oven at 100°C for 24 hours, after the reaction is completed and cool to room temperature, the mixed solution is centrifuged to obtain a white product, and the product is obtained at 100°C Dry, wash the dried product with hydrochloric acid-ethanol mixed solution until neutral, then place the washed solid in a muffle furnace, raise the temperature to 550 ºC at a heating rate of 1 ºC / min, and keep it for 6 h , to prepare mesoporous silica material. The mesoporous silica is baked in an oven to remove impurities adsorbed in the pores of the molecular sieve. A certain amount of 1-hexanol and chloroplatinic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com