Method for rapidly synthesizing molecular sieve supported nanometer photocatalyst

A nano-photocatalyst and photocatalyst technology, applied in the field of environmental governance, can solve problems such as time-consuming, high energy consumption, and reduced catalyst activity, and achieve an effect that is conducive to conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

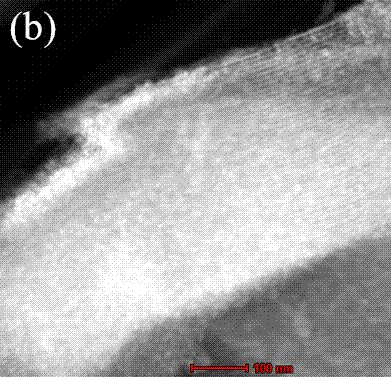

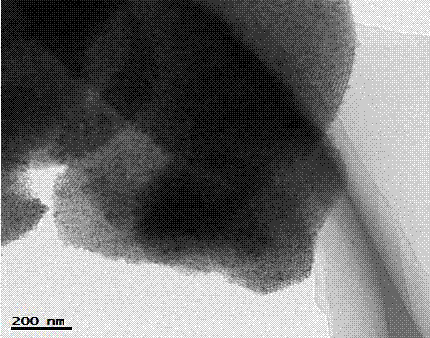

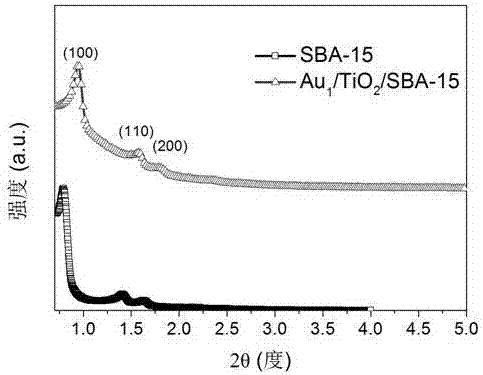

[0019] Take the SBA-15 powder and put it in an oven to bake to remove the impurities adsorbed in the pores of the molecular sieve. Add 1 g of SBA-15 to 20 mL of absolute ethanol and glacial acetic acid for ultrasonic dispersion for 10 minutes, then add the titanium dioxide precursor drop by drop, place the mixture in a negative pressure system, and use the capillary force of the molecular sieve mesoporous to dissolve the titanium dioxide precursor absorbed into the pores. After stirring for 1 hour under magnetic stirring conditions, the mixed liquid was transferred to a 70 mL polytetrafluoroethylene-lined hydrothermal reactor, and then placed in a microwave digestion apparatus (MDS-6, Shanghai, China) at 180 o C temperature for 30 minutes to synthesize TiO 2 / SBA-15. A certain amount of 1-hexanol and chloroauric acid solution (10 mg / mL) was added dropwise to TiO 2 In / SBA-15, the mixed liquid is placed in a negative pressure system, and the precursor of metal nanoparticles ...

Embodiment 2

[0021] Take the SBA-15 powder and put it in an oven to bake to remove the impurities adsorbed in the pores of the molecular sieve. Add 1 g of SBA-15 to 20 mL of absolute ethanol and glacial acetic acid for ultrasonic dispersion for 10 minutes, then add the titanium dioxide precursor drop by drop, place the mixture in a negative pressure system, and use the capillary force of the molecular sieve mesoporous to dissolve the titanium dioxide precursor absorbed into the pores. After stirring for 1 hour under magnetic stirring conditions, the mixed liquid was transferred to a 70 mL polytetrafluoroethylene-lined hydrothermal reactor, and then placed in a microwave digestion apparatus (MDS-6, Shanghai, China) at 180 o C temperature for 30 minutes to synthesize TiO 2 / SBA-15. A certain amount of 1-hexanol and chloroplatinic acid solution was added dropwise to TiO 2 In / SBA-15, the mixed liquid is placed in a negative pressure system, and the precursor of metal nanoparticles is sucke...

Embodiment 3

[0023] Take the SBA-15 powder and put it in an oven to bake to remove the impurities adsorbed in the pores of the molecular sieve. Add 1 g of SBA-15 to 20 mL of absolute ethanol and glacial acetic acid for ultrasonic dispersion for 10 minutes, then add the titanium dioxide precursor drop by drop, place the mixture in a negative pressure system, and use the capillary force of the molecular sieve mesoporous to dissolve the titanium dioxide precursor absorbed into the pores. After stirring for 1 hour under magnetic stirring conditions, the mixed liquid was transferred to a 70 mL polytetrafluoroethylene-lined hydrothermal reactor, and then placed in a microwave digestion apparatus (MDS-6, Shanghai, China) at 180 o C temperature for 30 minutes to synthesize TiO 2 / SBA-15. A certain amount of 1-hexanol and silver nitrate solution was added dropwise to TiO 2 In / SBA-15, the mixed liquid is placed in a negative pressure system, and the precursor of metal nanoparticles is sucked int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com