Water cooling mold for low-pressure casting of aluminum alloy wheel

A low-pressure casting and aluminum alloy technology, applied in the field of aluminum alloy low-pressure casting, can solve the problems of shrinkage at the root of the spokes, unreasonable design of the water-cooling structure of the side mold, etc., and achieve the effect of reducing thermal deformation, reducing mold cost, and improving mold life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

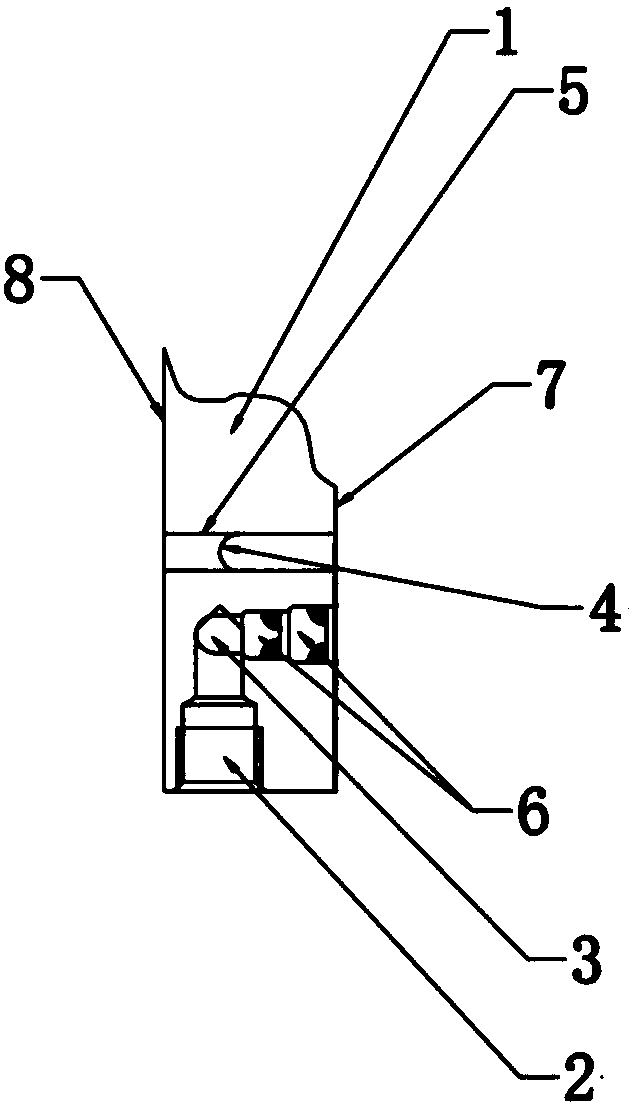

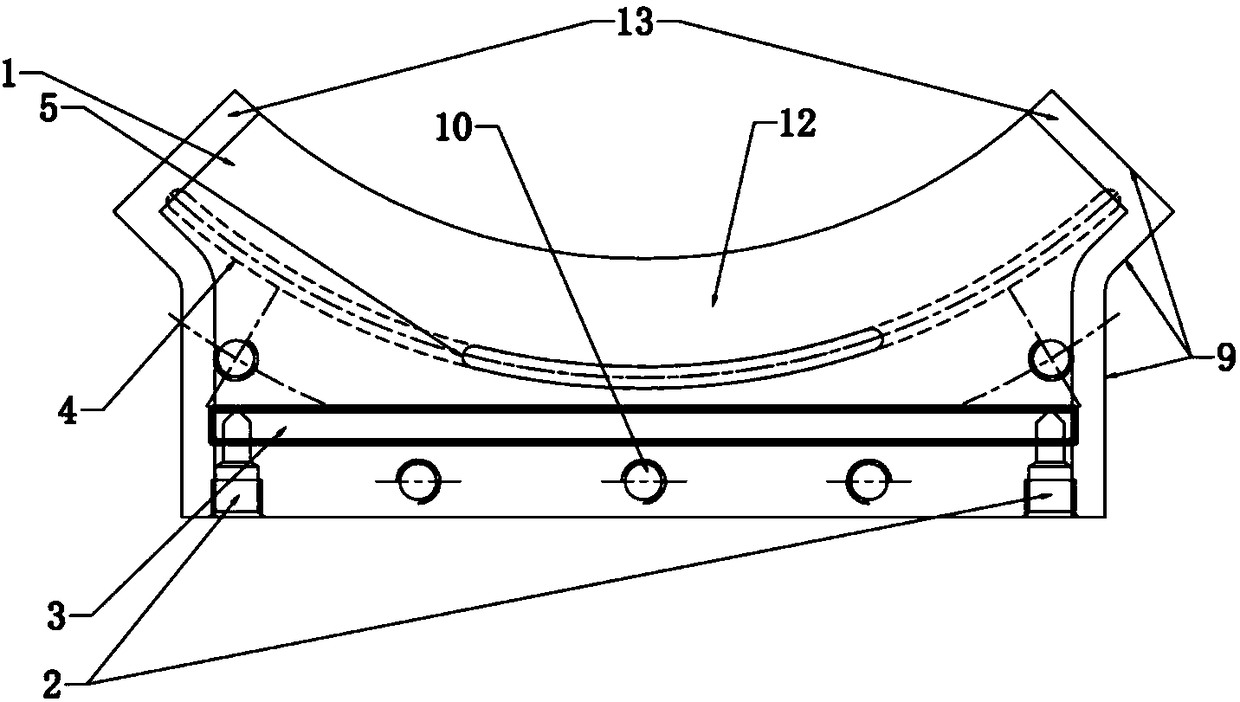

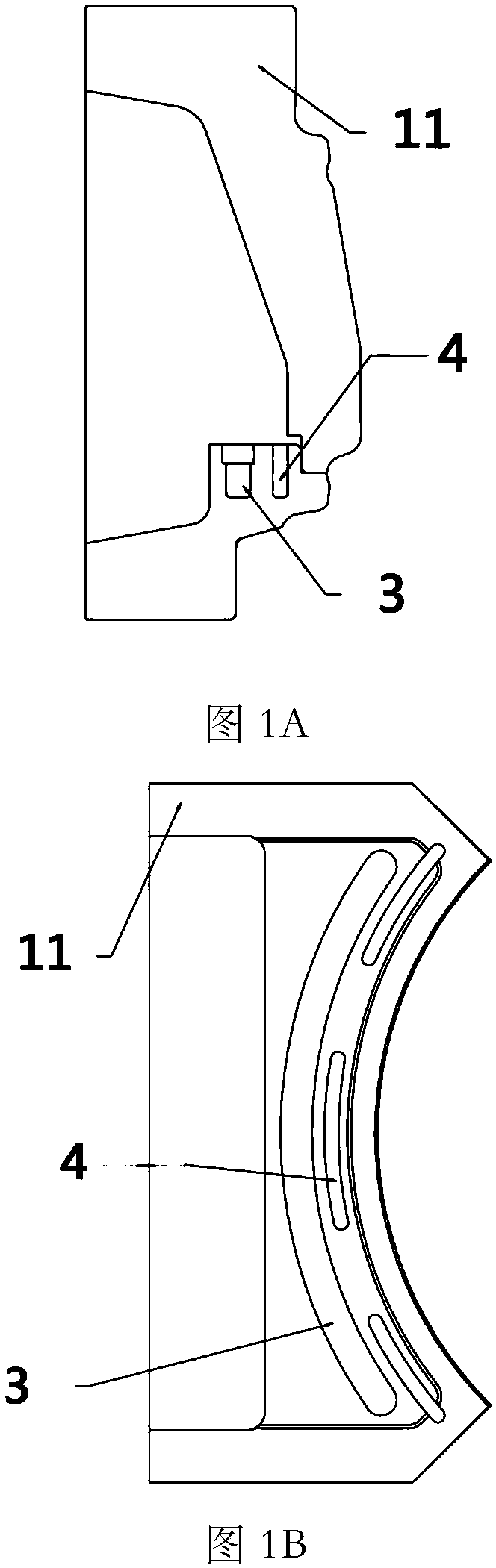

[0020] The improved side mold water cooling structure of the present invention includes a cooling insert 1 and a side mold frame 11 .

[0021] First, process the cooling insert 1 and the side mold frame 11 of the corresponding size according to the drawing requirements. And on the upper parting surface 8 and the lower parting surface 7 of the cooling insert 1, except for the 10-15mm assembly surface 13 reserved on both sides, a 0.2mm avoidance area 12 is processed.

[0022] Then, the bolt holes 10 are processed on the cooling insert 1, and the through holes 14 are processed on the side mold frame 11.

[0023] Finally, a cooling water channel 3 , a blind hole heat insulation groove 4 , a through hole heat insulation groove 5 , and a double-layer sealing baffle 6 for sealing are processed on the cooling insert 1 . Buckle the sealing baffle into the cooling channel 3 and weld it to fix it.

[0024] After the above work is completed, the cooling insert 1 can be embedded in the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap | aaaaa | aaaaa |

| Gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com