A water-cooled metal reflector

A metal mirror and water-cooling technology, applied in the field of laser technology and optics, to achieve the effects of reducing thermal denaturation, efficient cooling, and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

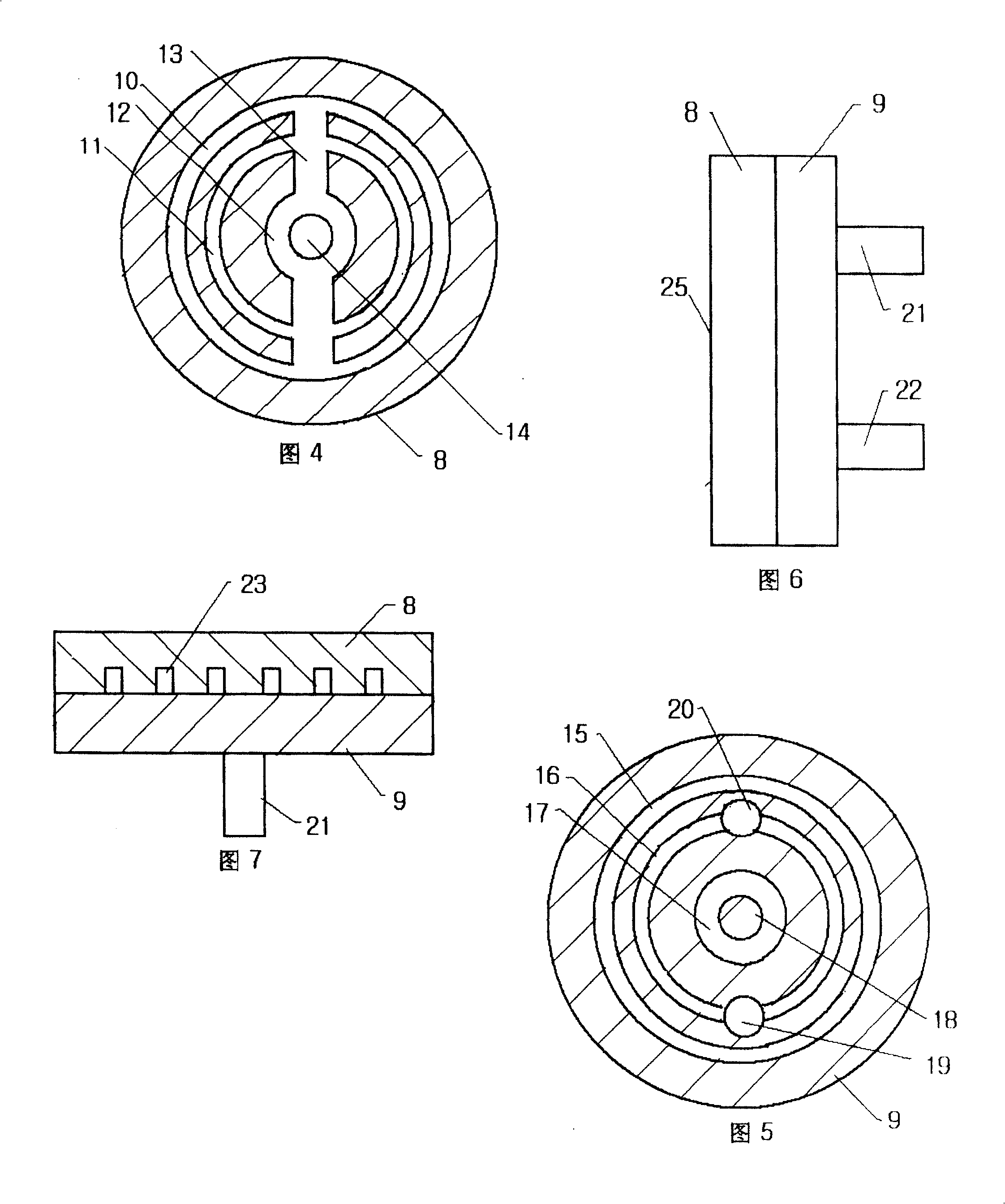

[0010] Embodiment 1: The structure of a water-cooled metal mirror is shown in Figure 4, Figure 5, Figure 6 and Figure 9 As shown, there are two metal parts 8, 9, and one side of the metal parts 8, 9 has concentric circular grooves 23, 24, which are symmetrical to each other, and one of the concentric circular grooves 10, 11, 12 of one metal part 8 has The straight groove 13 is connected and communicated, and the concentric grooves 15, 16 and 17 of the other metal part 9 have two through holes 19 and 20 respectively connected to the water inlet 21 and the water outlet 22. The faces with concentric grooves are welded together. The center of the metal part has shunt circles 14, 18.

[0011] The other surface of the metal component 1 is a metal mirror reflection surface 25, and the metal mirror reflection surface 25 is a curved surface including a circular arc surface and a combined arc surface.

[0012] A water-cooled metal reflector formed by welding two metal parts 8 and 9 i...

Embodiment 2

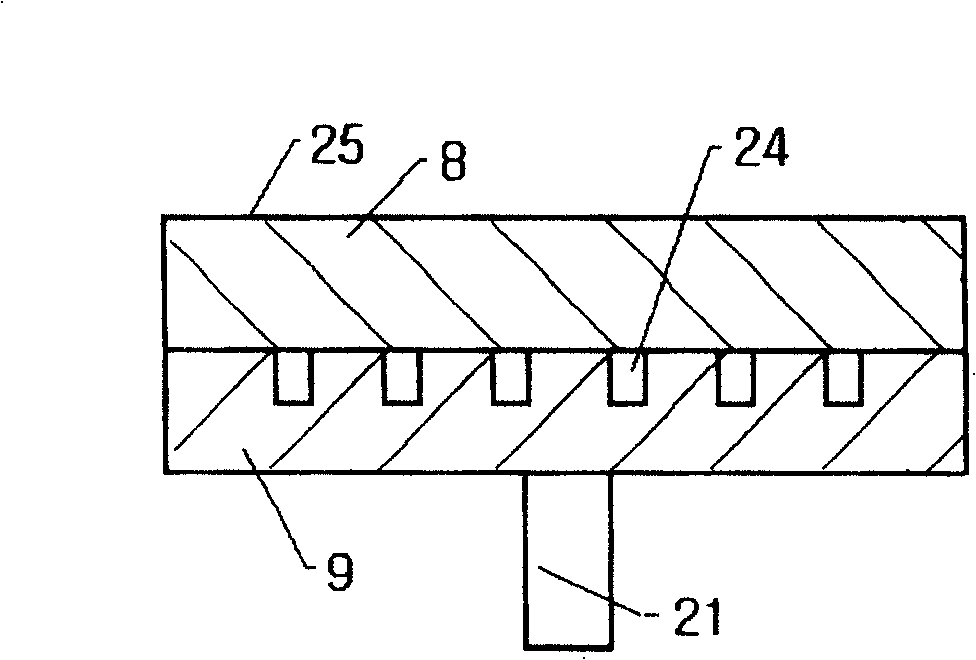

[0016] Embodiment 2: As shown in Figure 7, it is a schematic structural diagram of a water-cooled metal mirror used in a high-power laser processing system. For the two metal parts 8 and 9, one side of the metal part 8 has concentric circular grooves 23, and between the concentric circular grooves 23 there is a straight-through groove for connection and communication, and the other metal part 9 has no concentric circular grooves. Other structures are the same as in Example 1.

[0017] The two parts of the water-cooled metal mirror are sealed with low-temperature metal solder at the contact surface of the non-flow channel, forming a whole as shown in Figure 7. The outer diameter of the mirror surface is 70mm, the height of the metal mirror is 25mm, the height of the inner channel of the metal mirror is 1.5mm, the width of the channel is 3mm, the distance between adjacent channels is 9mm, and the diameter of the central branch circle is 6mm. There are three types of six channel...

Embodiment 3

[0022] Example 3: as Figure 8 As shown, two metal parts 8 and 9, one side of the metal part 9 has concentric circular grooves 24, and there are straight grooves connecting and communicating between the concentric circular grooves 24, and the other metal part 8 has no concentric circular grooves. Other structures are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com