Automatic insulator assembly method based on visual detection technology

A visual inspection and automatic assembly technology, which is applied in image data processing, instruments, computer parts, etc., can solve the problems of high cost, low efficiency, and prone to errors, and achieve high assembly efficiency, continuous work, and labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with accompanying drawing:

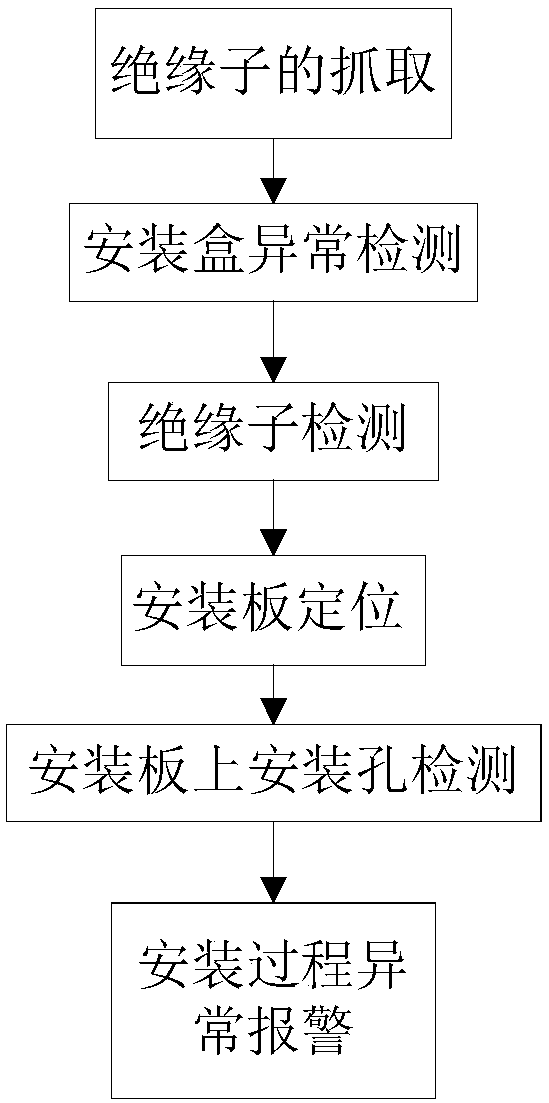

[0042] Such as Figure 1-5 As shown, an automatic assembly method for insulators based on visual inspection technology includes the following steps:

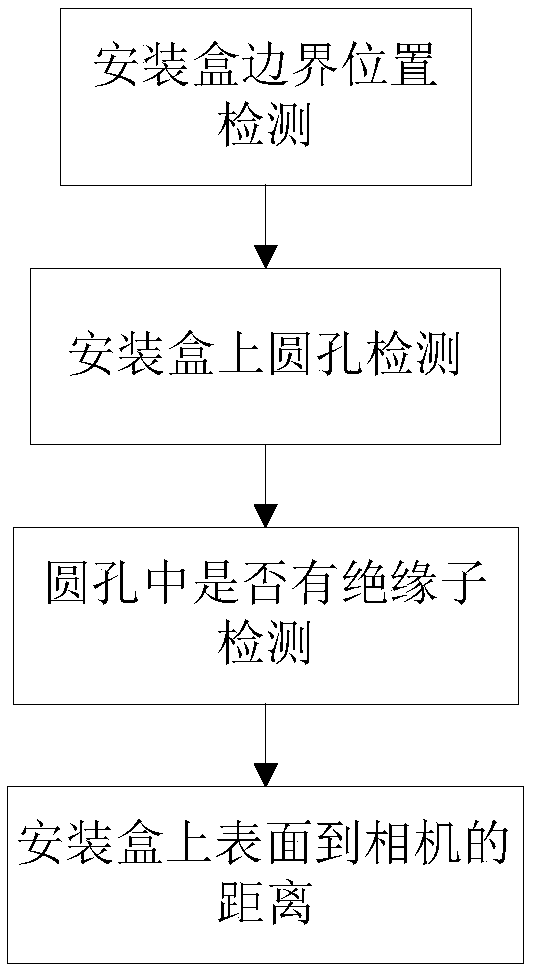

[0043] S1: Grab the insulator: Use the robotic arm to capture the boundary of the installation box that stores the insulator, and locate the position of the installation box. The specific positioning process is as follows:

[0044] S11: Capture images with an industrial camera installed on the robotic arm;

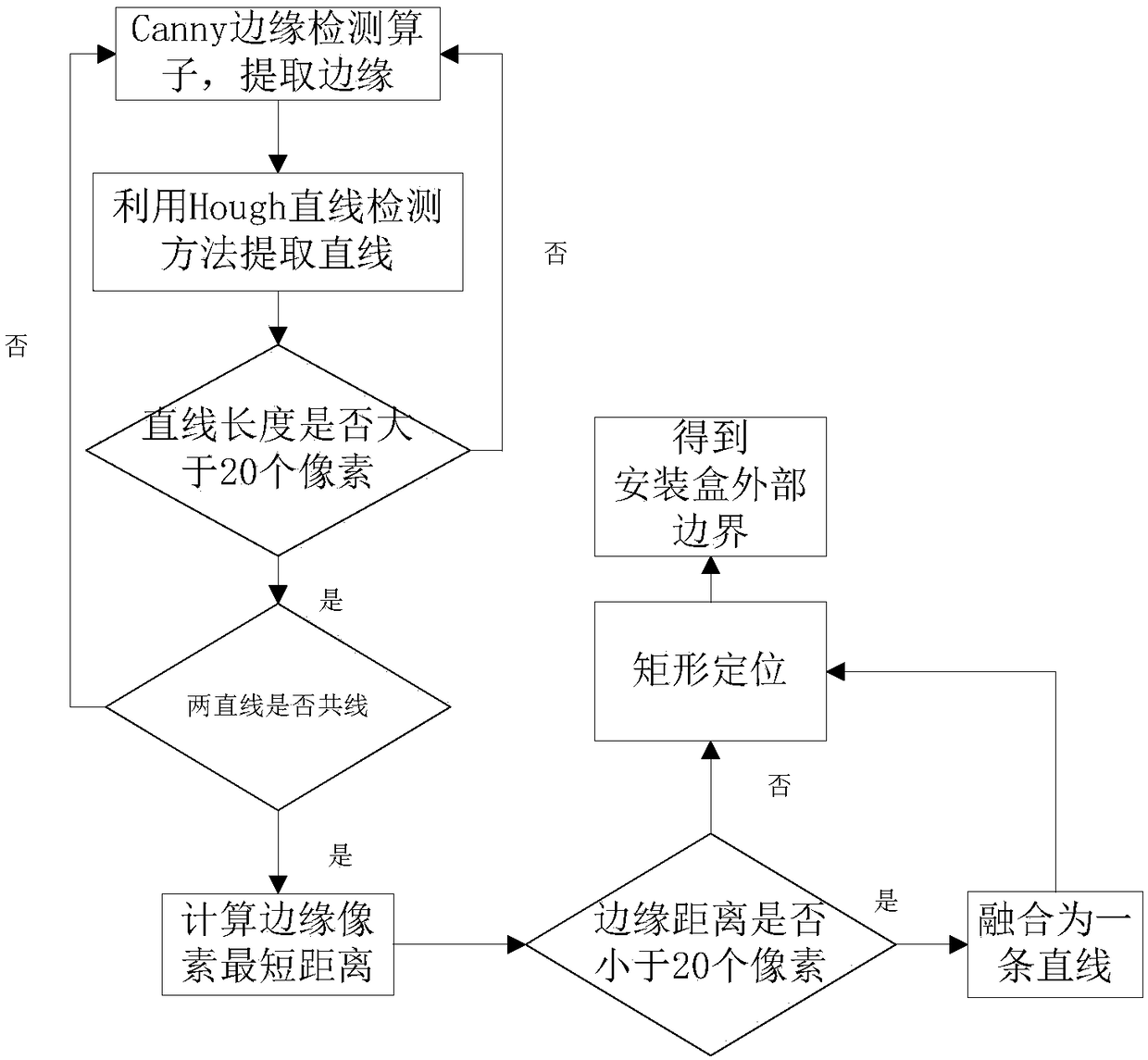

[0045] S12: using the Canny edge detection operator to extract edges;

[0046] S13: traverse all the edge pixels, use the Hough line detection method to extract the line, and calculate the equation corresponding to the line;

[0047] S14: filtering straight lines with a length less than 20 pixels;

[0048] S15: Analyze all straight lines with a length greater than 20 pixels, and find collinear straight lines:

[0049...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com