Production process of laminated glass

A laminated glass, production process technology, applied in the direction of glass/slag layered products, layered products, synthetic resin layered products, etc., can solve the problem of insufficient bonding strength and achieve good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

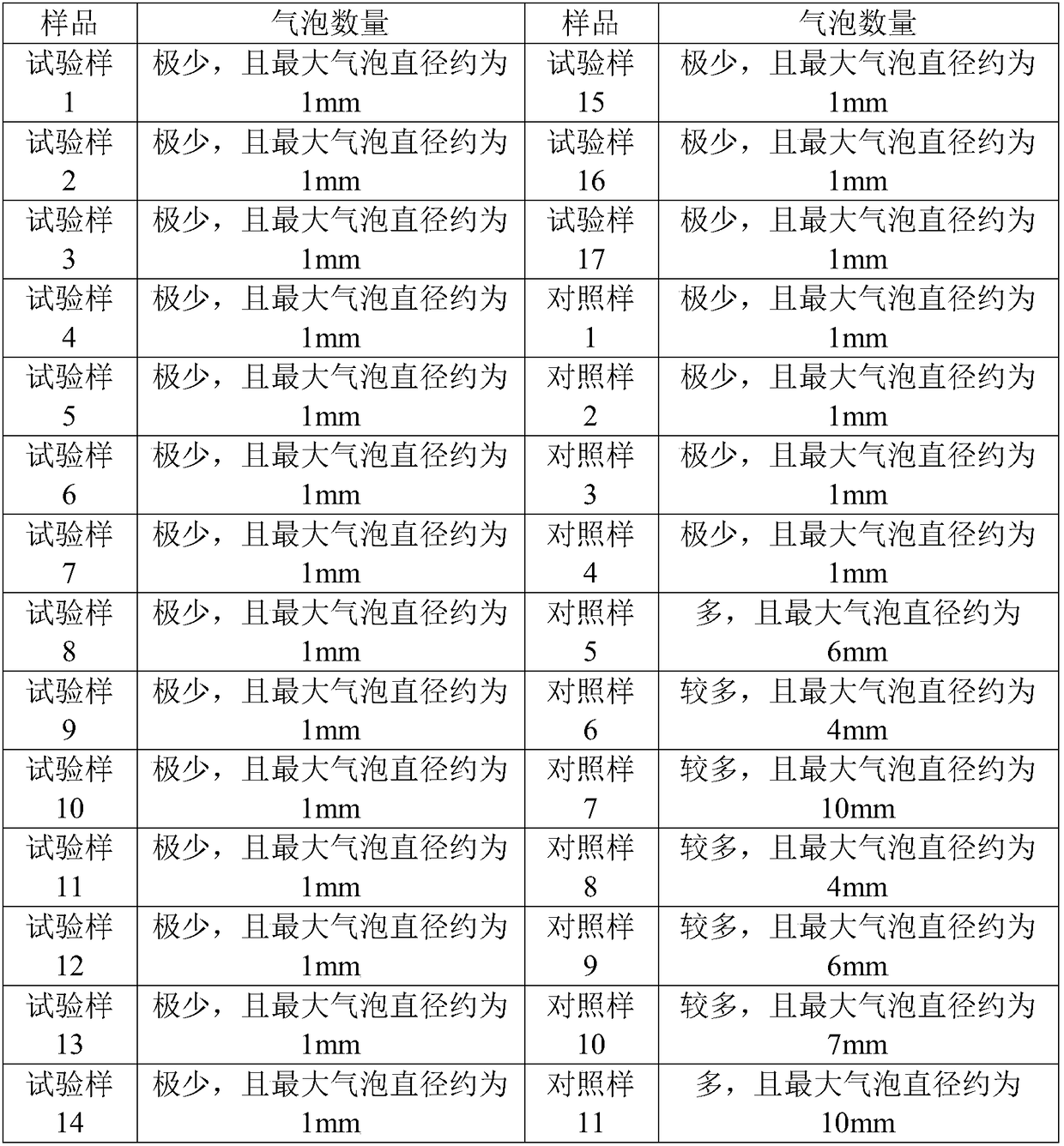

Examples

Embodiment 1

[0053]Embodiment 1: A kind of production technology of laminated glass, is produced and obtained through the following steps:

[0054] Step 1, cutting, grinding and cleaning the large glass raw material to obtain the original glass sheet;

[0055] Step 2, merging: put a layer of composite membrane between two layers of glass original sheets, and the ratio of the thickness of the glass original sheet to the thickness of the composite membrane is 7.5:1, cut and remove the excess composite membrane, form glass sheets;

[0056] Step 3, heating and pressing: Preheat and prepress the glass composite obtained in step 2. The preheating temperature is 60°C, and the preheating time is 15 minutes; the prepressing pressure is 1.1MPa; the prepressing The time is 15 minutes; after the composite diaphragm is softened, it is then put into an autoclave for hot-press molding to obtain laminated glass.

[0057] Wherein, the components included in the composite membrane and their parts by weigh...

Embodiment 2-5

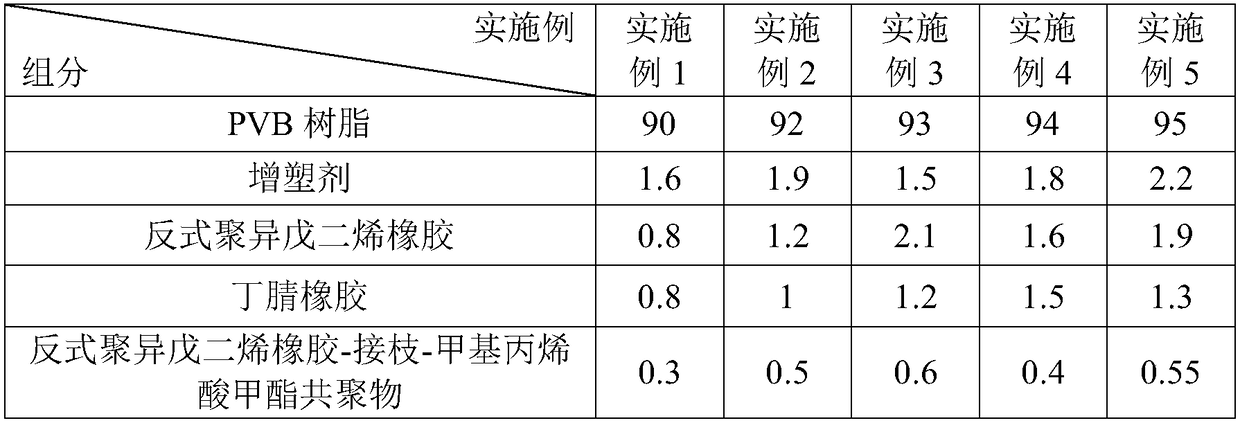

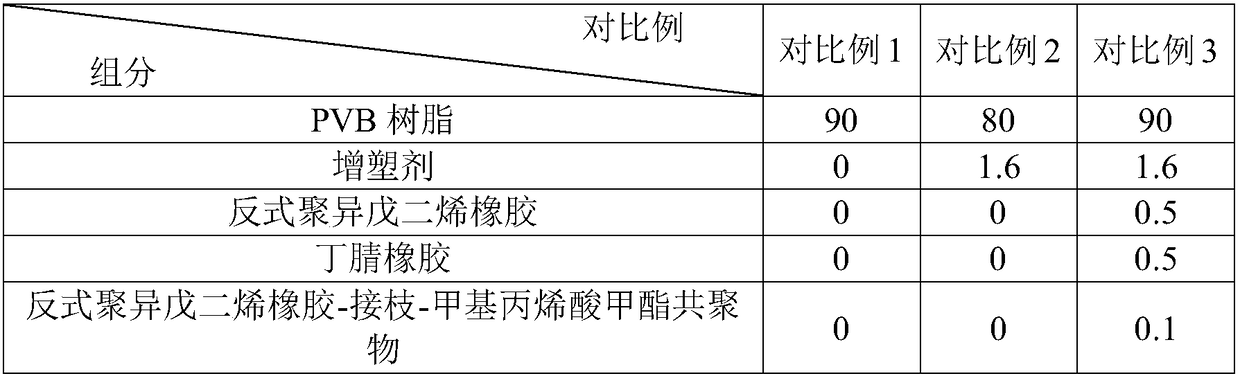

[0064] Example 2-5: A production process of laminated glass, the difference from Example 1 is that the components and parts by weight included in the composite film are shown in Table 1.

[0065] Components and parts by weight thereof included in the composite membrane in Table 1 embodiment 1-5

[0066]

Embodiment 6

[0067] Embodiment 6: A production process of laminated glass, the difference from Example 1 is that in the production process of laminated glass, in step 2, the ratio of the thickness of the original glass sheet to the thickness of the composite film is 12:1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com