Quantitative loading system and method for loading powdery materials

A powdery material and material technology, which is applied in the field of powdery material automobile loading, can solve the problems of low degree of automation, low loading efficiency, and easy agglomeration of powdery materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

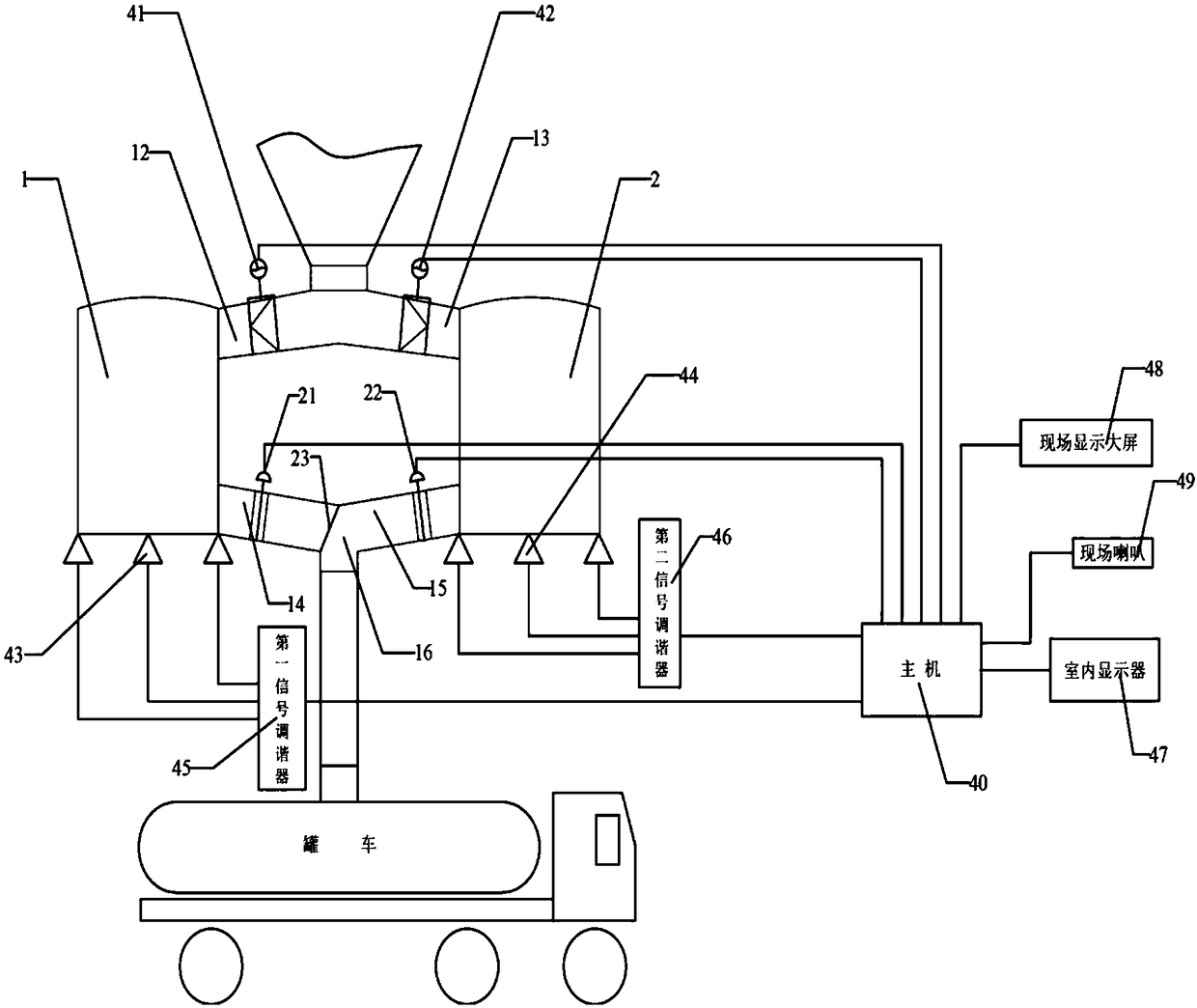

[0052] Embodiment 1 provides a quantitative loading system for loading powdery materials, and the structure of Embodiment 1 will be described in detail below.

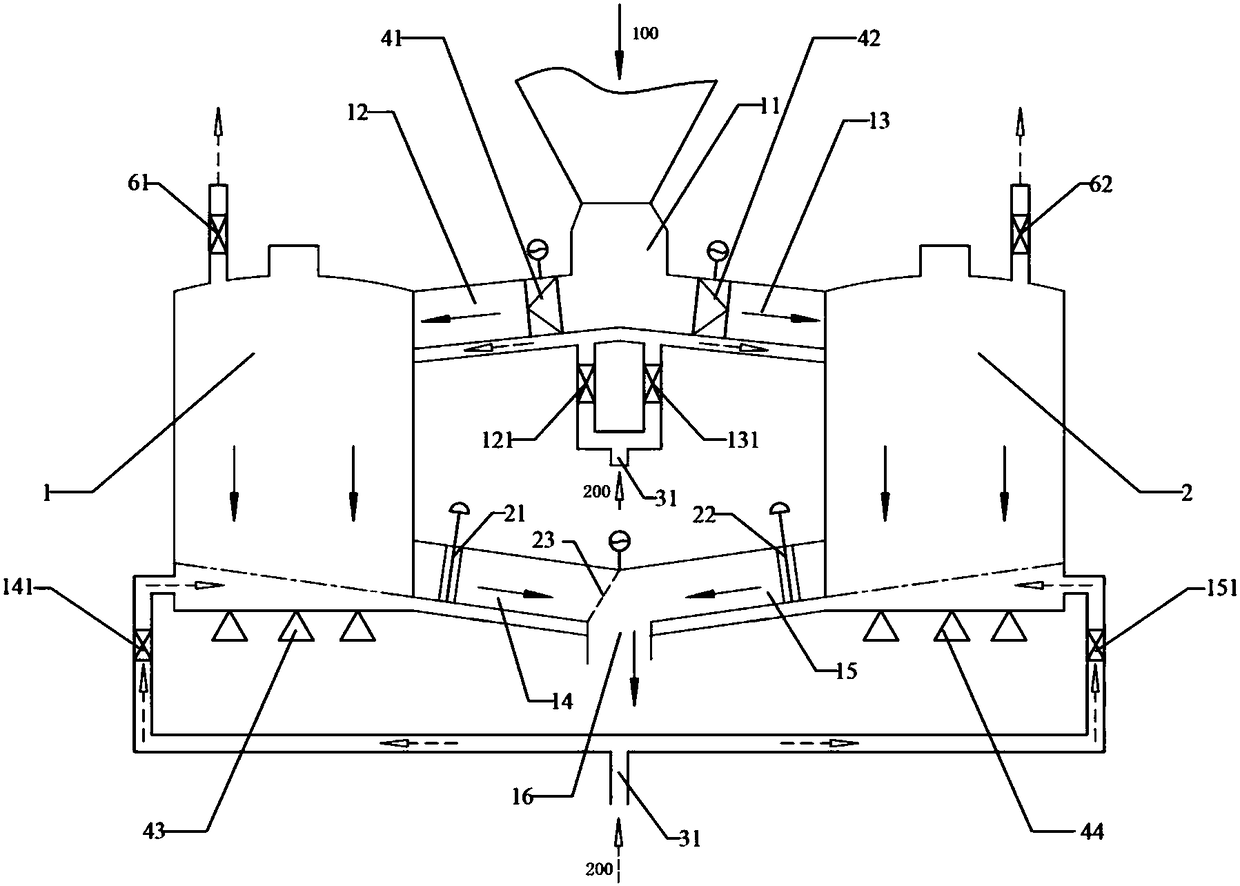

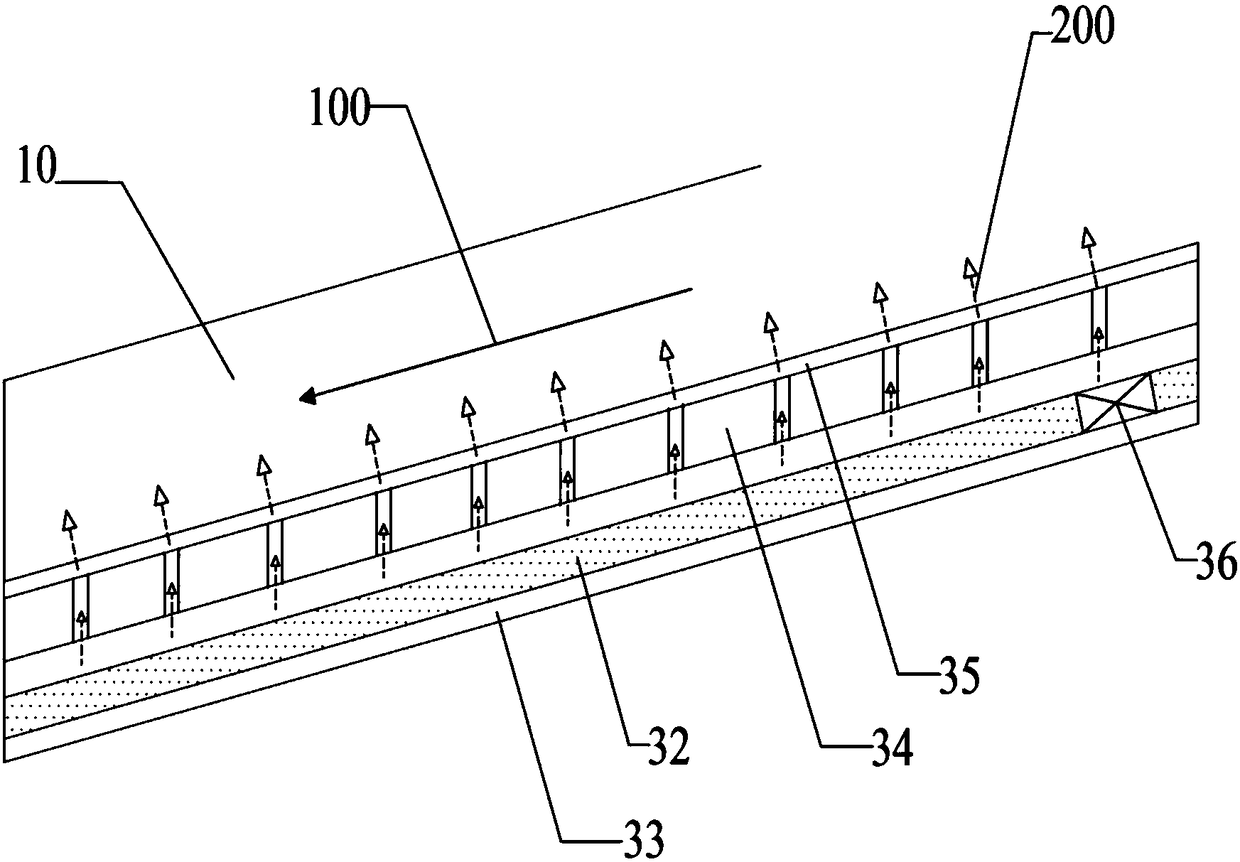

[0053] refer to figure 1 , The quantitative loading system includes a material conveying system, an air material conveying system and a material quantitative weighing system.

[0054] The material conveying system includes a warehouse material inlet 11, a storage bin, a material pipeline 10, a material gate valve and a material outlet 16. The storage bins and between the storage bins and the discharge port 16 are communicated through the material pipeline 10 , and the material gate valve is arranged in the material pipeline 10 .

[0055] Further, the storage bin includes a first bin 1 and a second bin 2, and the first bin 1 and the second bin 2 are independently arranged side by side.

[0056] Further, the material pipeline 10 includes a first feed chute 12, a second feed chute 13, a first discharge chute 14, a secon...

Embodiment 2

[0068] This embodiment 2 provides a quantitative loading method for loading powdery materials. The quantitative loading system for loading powdery materials provided in embodiment 1 is adopted. Before the tanker starts to be loaded, the fan is in working condition, and the main The air pipe port 31 continues to receive compressed gas, the gas material pipeline 32 is filled with compressed gas, and the capacity of the first silo 1 and the second silo 2 is the same, the maximum weight of the powdery material that can be accommodated is the capacity limit w, and the tanker needs The weight of the loaded powdery material is the preloaded weight T, and the preloaded weight T is greater than 2 times the capacity limit w, the weight of the powdery material loaded into the tanker is the loading weight t, the quantitative loading provided by the present embodiment 2 is as follows The method is described in detail, and the quantitative loading method includes the following steps:

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com