Batch production method of high quality graphene

A production method and graphene technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of difficult access of solvent molecules and large volume of organic molecules, etc., with short time to achieve, complete crystal structure, and good quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

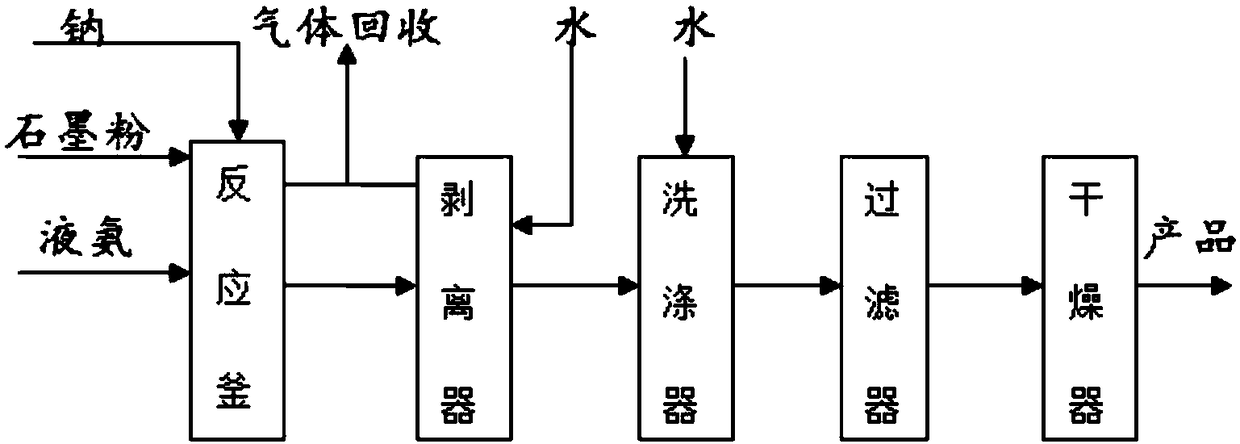

Method used

Image

Examples

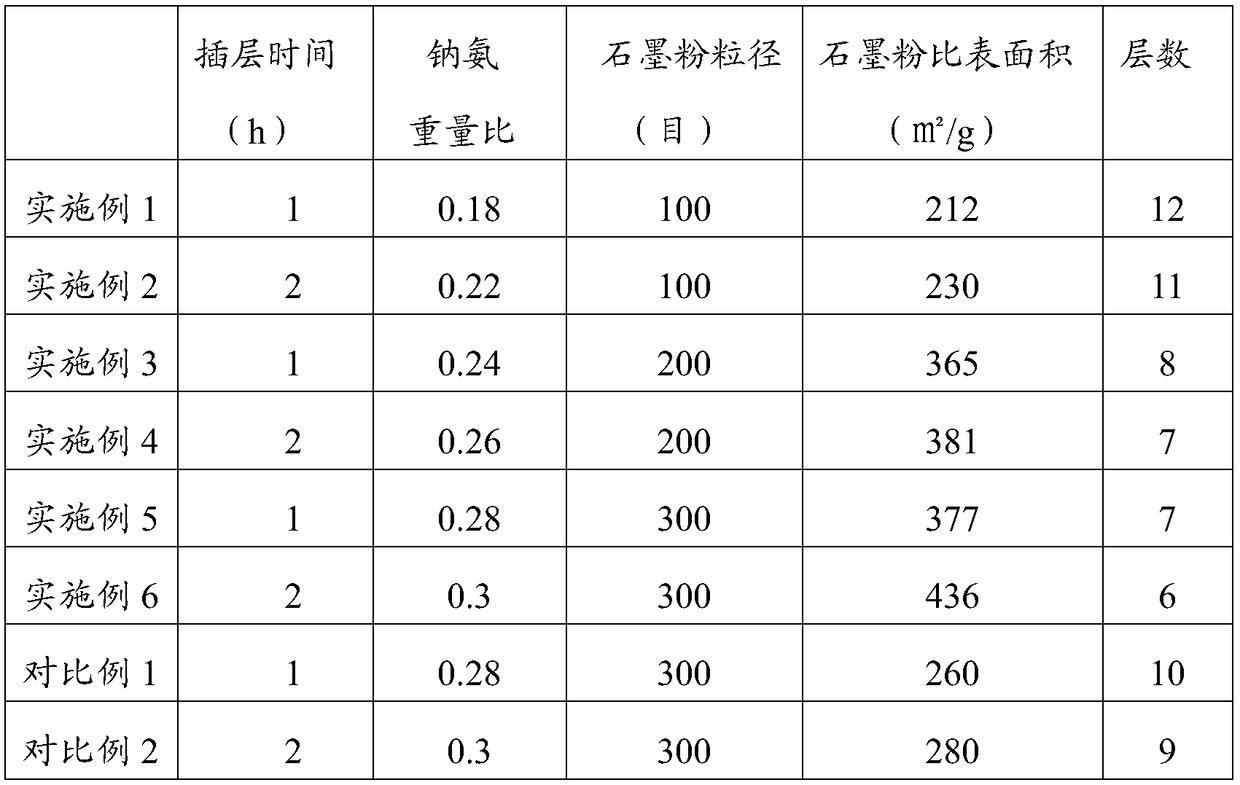

Embodiment 1

[0024] A batch production method of high-quality graphene, comprising the following steps:

[0025] Step 1: Add 100-mesh natural graphite powder with a purity of more than 99.8% into a reactor filled with ammonia;

[0026] Step 2: Add metal sodium and liquid ammonia to the reaction kettle in step 1 in sequence to obtain a mixed liquid, wherein the weight ratio of sodium to liquid ammonia is 0.18, maintain the temperature at 25°C for 1 hour, and control the pressure at 1.1Mpa;

[0027] Step 3: heating the reaction kettle in step 2 until the liquid ammonia evaporates to obtain sodium-intercalated graphite powder, wherein the liquid ammonia evaporates and enters the gas recovery system;

[0028] Step 4: Put the sodium intercalated graphite powder into the stripper and add water to react;

[0029] Step 5: washing, filtering and drying the material obtained in step 4 to obtain a graphene product.

[0030] In order to obtain graphene with different layers, the steps 1-5 can be car...

Embodiment 2

[0032] A batch production method of high-quality graphene, comprising the following steps:

[0033] Step 1: Add 100-mesh natural graphite powder with a purity of more than 99.8% into a reactor filled with ammonia;

[0034] Step 2: Add metal sodium and liquid ammonia to the reaction kettle in step 1 in sequence to obtain a mixed liquid, wherein the weight ratio of sodium to liquid ammonia is 0.22, maintain the temperature at 31°C for 2 hours, and control the pressure at 1.2Mpa;

[0035] Step 3: heating the reaction kettle in step 2 until the liquid ammonia evaporates to obtain sodium-intercalated graphite powder, wherein the liquid ammonia evaporates and enters the gas recovery system;

[0036] Step 4: Put the sodium intercalated graphite powder into the stripper and add water to react;

[0037] Step 5: washing, filtering and drying the material obtained in step 4 to obtain a graphene product.

[0038] In order to obtain graphene with different layers, the steps 1-5 can be ca...

Embodiment 3

[0040] A batch production method of high-quality graphene, comprising the following steps:

[0041] Step 1: Add 200-mesh natural graphite powder with a purity of more than 99.8% into a reactor filled with ammonia;

[0042] Step 2: Add metal sodium and liquid ammonia to the reaction kettle in step 1 in sequence to obtain a mixed liquid, wherein the weight ratio of sodium to liquid ammonia is 0.24, maintain the temperature at 33°C for 1 hour, and control the pressure at 1.3Mpa;

[0043] Step 3: heating the reaction kettle in step 2 until the liquid ammonia evaporates to obtain sodium-intercalated graphite powder, wherein the liquid ammonia evaporates and enters the gas recovery system;

[0044] Step 4: Put the sodium intercalated graphite powder into the stripper and add water to react;

[0045] Step 5: washing, filtering and drying the material obtained in step 4 to obtain a graphene product.

[0046] In order to obtain graphene with different layers, the steps 1-5 can be car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com