A kind of multi-component composite ti(c,n) cermet and preparation method thereof

A multi-component composite and cermet technology, which is applied in the field of ceramic matrix composite materials, achieves the effects of shortening the preparation process, short holding time, and reducing raw material costs and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The invention provides a method for preparing multi-element composite Ti(C,N) cermets, comprising:

[0048] A) Ti source, M source and carbon source, and nickel source and / or cobalt source are mixed, and ball milled to obtain activated raw material powder; The M is Mo, W, Ta, Nb, V, Cr, La and Y any one or several;

[0049] B) The prepared activated raw material powder is subjected to discharge plasma in-situ carbothermal reduction reaction and sintering to obtain a multi-component composite Ti(C,N) cermet.

[0050] In the present invention, firstly, the metal oxide raw material is pretreated by mechanical ball milling to obtain evenly mixed raw material fine powder. Next, using the discharge plasma technology, the activated powder is used as the raw material, and the cermet material is obtained by direct and rapid reaction sintering. The present invention omits the two steps in the prior art that the cermet raw material powder needs to be separately prepared in advan...

Embodiment 1

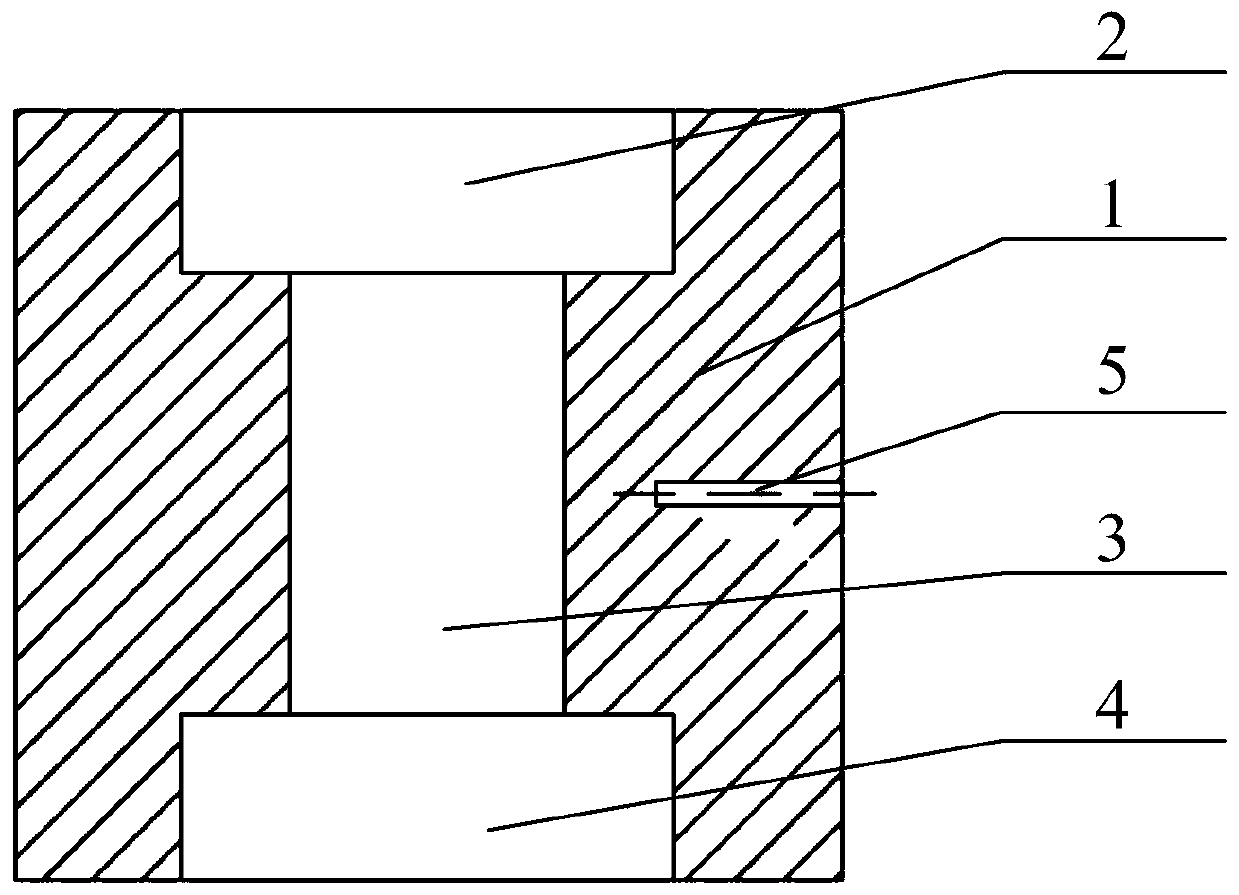

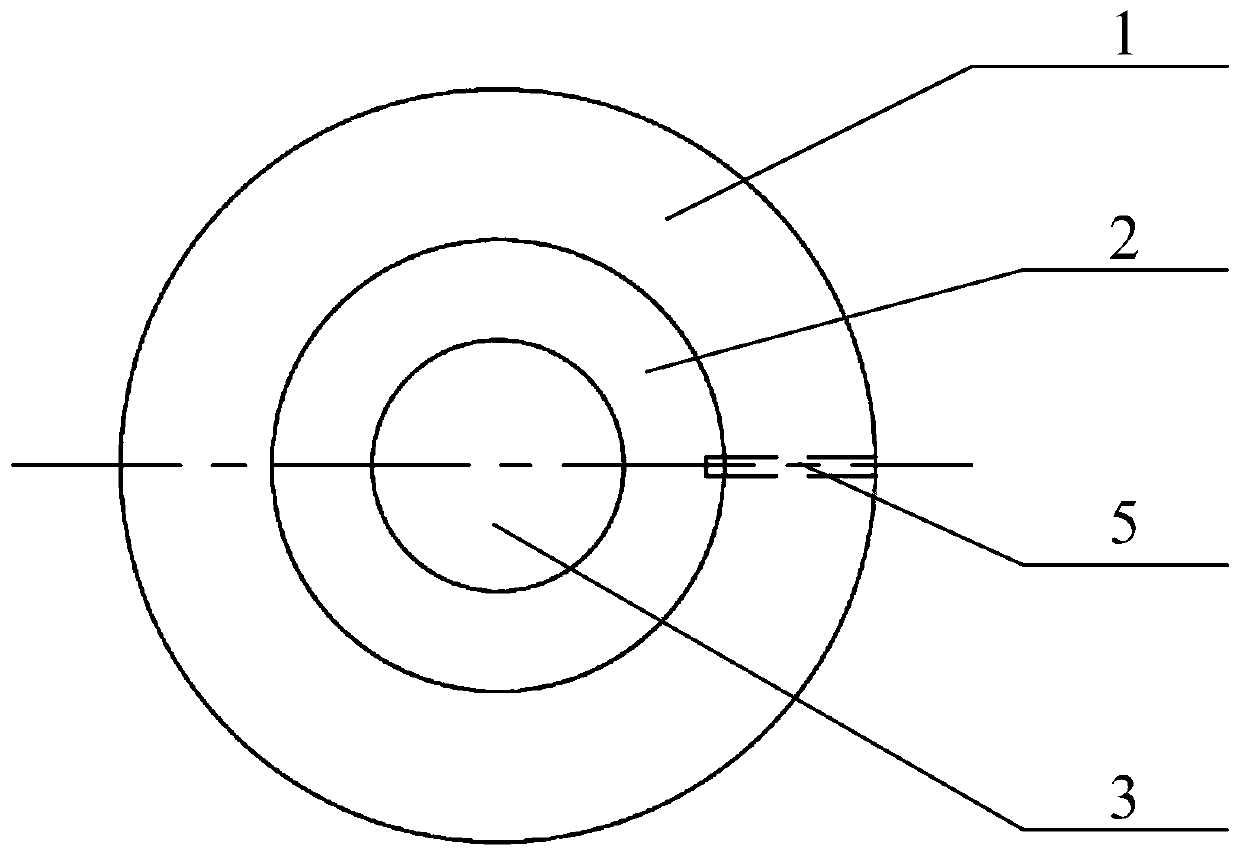

[0078] The graphite mold that the present invention adopts please refer to Figure 3 to Figure 5 ,in, image 3 and Figure 4 Both are schematic diagrams of the first cover. The installation methods of the first cover and the second cover are similar. For the installation direction of the second cover, please refer to Figure 3 to Figure 4 .

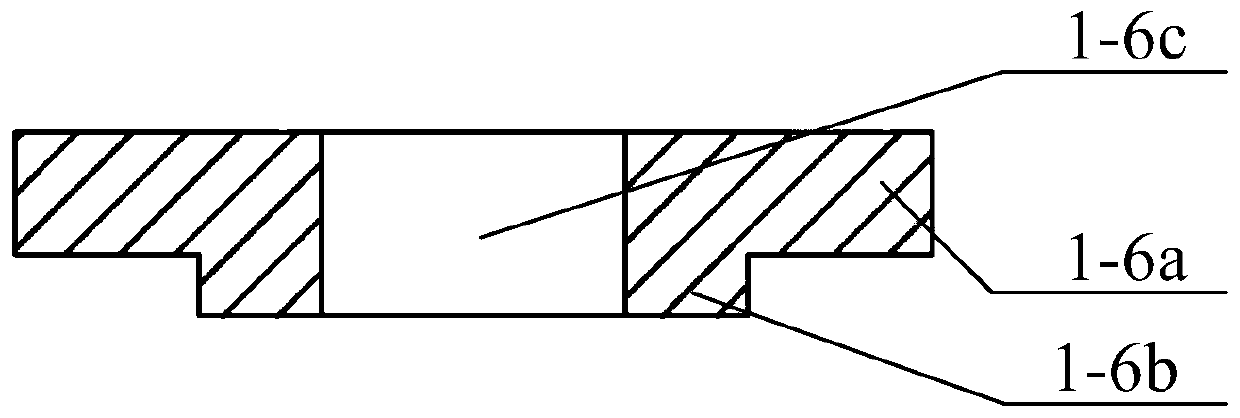

[0079] In this embodiment, the first cover plate 1-6 and the second cover plate 1-7 both include a first end and a second end, the diameter of the first end is greater than the diameter of the second end, and the second end of the first cover plate 1-6b is used to be placed in the first cover plate hole 2, and there is a gap between the second end 1-6b of the first cover plate and the bottom end of the first cover plate hole 2, the first end of the first cover plate 1-6a and the stepped surface formed by the second end 1-6b of the first cover plate is used to abut against the main body 1;

[0080] The second end of the second cover pl...

Embodiment 2

[0087] (1) Preparation and ingredients of raw material powder

[0088] According to the prepared (Ti,15W,10Mo)(C 0.7 ,N 0.3 )-(Ni,Co) target product, determine the mass ratio of the initial raw materials, the raw material TiO 2 、WO 3 、MoO 3 、Co 4 o 3 , NiO and carbon powder weighing ingredients.

[0089] (2) Mechanical ball milling activation of raw material powder

[0090] Put the above-mentioned prepared raw materials into a ball mill tank, and put in balls at a ball-to-material ratio of 20:1, and perform mechanical ball milling on the raw materials for 35 hours on a high-energy ball mill to obtain evenly mixed fine powder of activated raw materials.

[0091] (3) Rapid preparation of product cermets

[0092] After putting the above-mentioned appropriate amount of activated raw material powder into the graphite mold, the mold is placed in the heating chamber of the discharge plasma system to carry out the discharge plasma in-situ carbothermal reduction reaction and si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com