Molecular sieve SCR catalyst and preparation method thereof

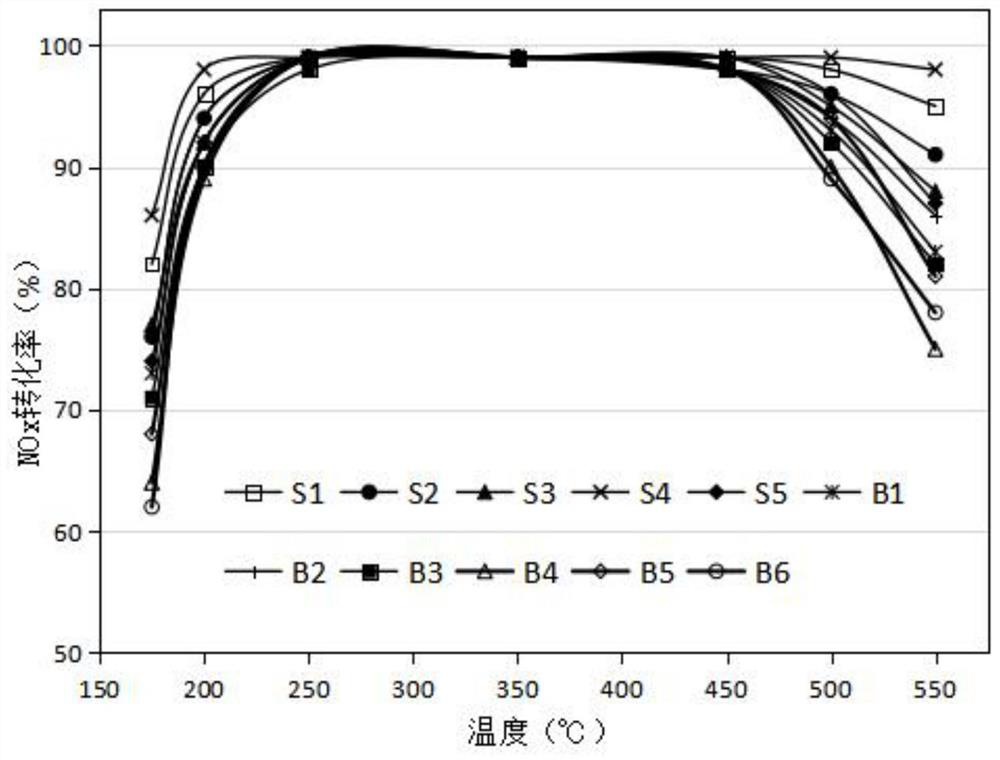

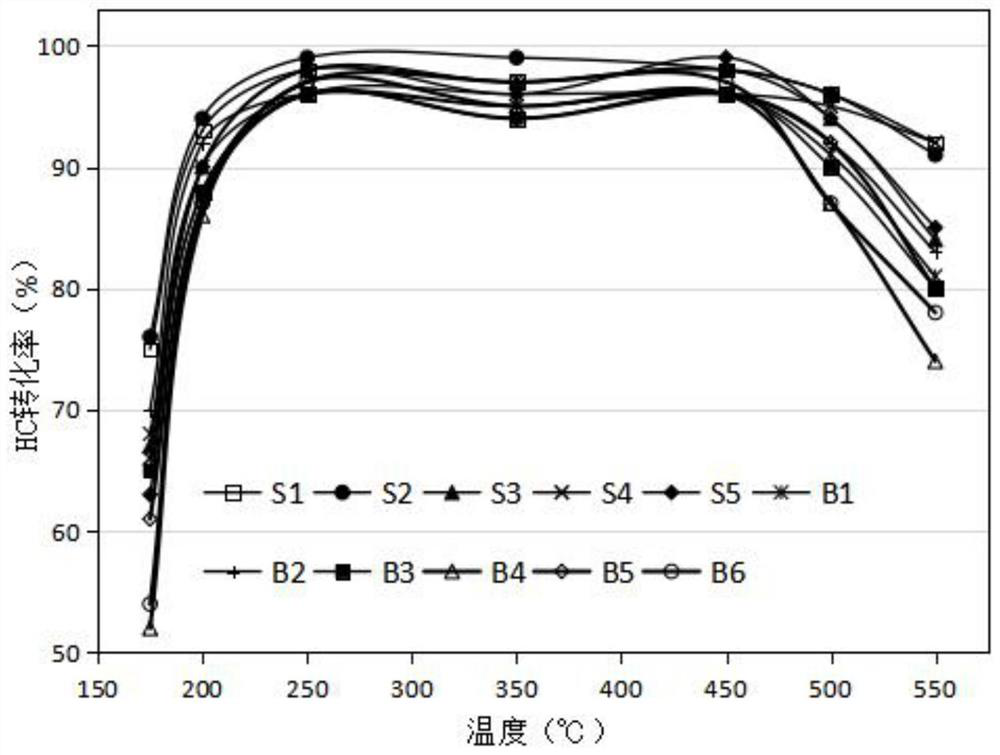

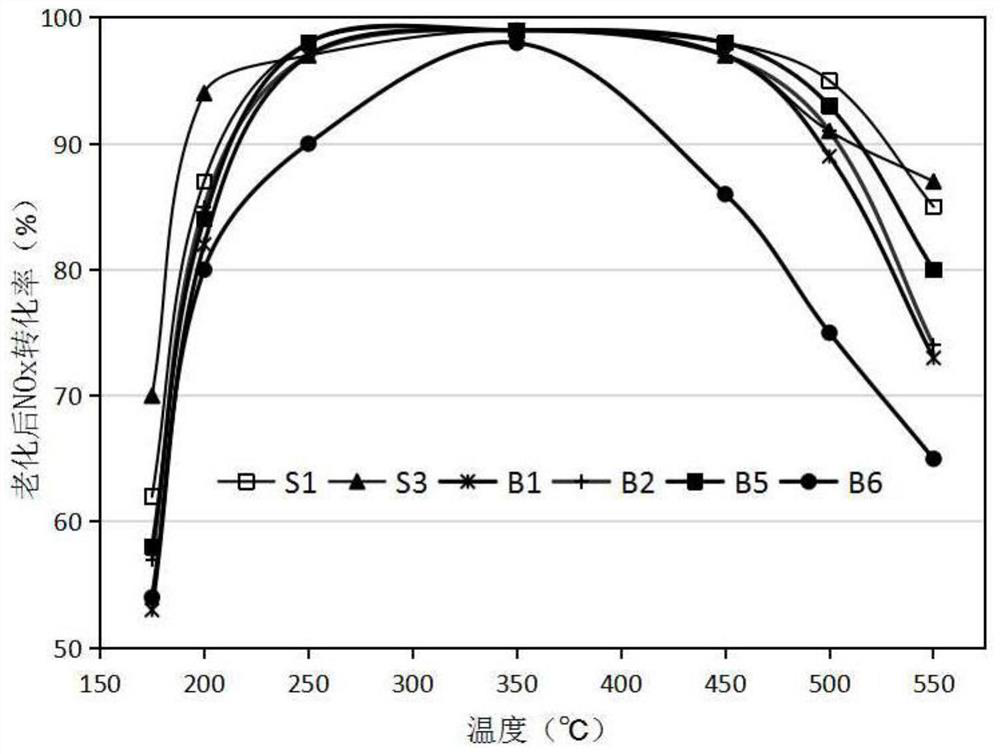

A technology of SCR catalyst and molecular sieve, which is applied in the field of molecular sieve SCR catalyst and its preparation, can solve the problems of low conversion rate, prone to hydrocarbon poisoning, high temperature performance degradation, etc., and achieve cost reduction, high hydrothermal stability, and wide activity temperature window Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Configuration of copper solution: heat 50 g of deionized water to 60° C., add 19.03 g of copper nitrate trihydrate and 6.05 g of citric acid, and stir to dissolve to prepare a copper solution.

[0036] (2) Ion exchange: heat 200g of deionized water to 80°C, add 6.03g of yttrium nitrate hexahydrate and stir to dissolve completely, keep the temperature at 80°C, add 140g of H-SSZ-13 with a silicon-to-aluminum ratio of 13, and keep stirring for 3h. For ion exchange, the copper solution prepared in step (1) was added with continuous stirring at a temperature of 80° C., and the solution was continuously stirred for 4 h.

[0037] (3) pulping: the solution after ion exchange in step (2) is lowered to room temperature, 28 g of silicon solution with a concentration of 30% is added, stirred, ball-milled, and allowed to stand for 1 hour to obtain a slurry;

[0038] (4) Coating and roasting: the slurry prepared in step (3) is coated on the cordierite carrier with a coating amoun...

Embodiment 2

[0041] (1) Configuration of copper solution: heat 100 g of deionized water to 80 °C, add 20.30 g of copper acetate, 8.60 g of citric acid and water, and stir and dissolve at 80 °C to prepare a copper solution.

[0042] (2) Ion exchange: heat 220g of deionized water to 80°C, add 3.88g of yttrium nitrate hexahydrate and stir to dissolve completely, keep the temperature at 80°C, add 16 and 180g H-SSZ-13 with a silicon-to-aluminum ratio and keep stirring for 1h. For ion exchange, the copper solution prepared in step (1) was added with continuous stirring at a temperature of 70° C., and was continuously stirred for 3 h.

[0043] (3) pulping: the solution after ion exchange in step (2) is lowered to room temperature, 36 g of silicon solution with a concentration of 30% is added, stirred, ball-milled, and allowed to stand for 1 hour to obtain a slurry;

[0044] (4) Coating and roasting: coating the slurry prepared in step (3) on the cordierite carrier with a coating amount of 140 g / L...

Embodiment 3

[0046] (1) Configuration of copper solution: heat 55 g of deionized water to 70° C., add 21.88 g of copper sulfate pentahydrate and 7.88 g of glycine, and stir to dissolve to prepare a copper solution.

[0047] (2) Ion exchange: heat 300g of deionized water to 70°C, add 8.62g of yttrium nitrate hexahydrate and stir to dissolve completely, keep the temperature at 70°C, add 20 and 200g H-SSZ-13 with a silicon-aluminum ratio and keep stirring for 6h. For ion exchange, the copper solution prepared in step (1) was added with continuous stirring at a temperature of 80° C., and the solution was continuously stirred for 4 h.

[0048] (3) pulping: the solution after the ion exchange in step (2) is lowered to room temperature, 57 g of zirconium sol with a concentration of 21% is added, stirred, ball-milled, and allowed to stand for 2 hours to obtain a slurry;

[0049] (4) coating and roasting: the slurry prepared in step (3) is coated on the cordierite carrier, the coating amount is 140...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com