A preparation method of coated liquid olefin microcapsules

A microcapsule, liquid state technology is applied in the field of preparation of microcapsules, which can solve the problems of cumbersome control of reaction conditions, complicated operation process and low level, and achieve the effects of simplifying the preparation process of capsules, simplifying the preparation process and efficient preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

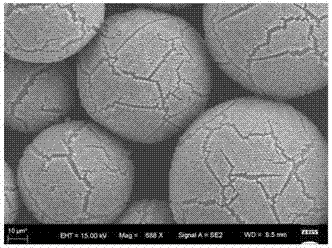

[0027] Embodiment 1: the preparation of encapsulating ethylenic restorative agent microcapsules

[0028] Mix 0.5g trimethylolpropane tris(3-mercaptopropionate), 0.42g isophorone diisocyanate and 2.14g triallyl isocyanurate to form an oil phase, and mix 0.15g SiO 2 The particles were added to 15g of water and stirred to disperse evenly to form a water phase. Add the obtained oil phase and water phase into a three-necked flask equipped with a stirrer, start the stirring and control the rotation speed at 1000rpm, and stir for 10min to obtain an oil-in-water Pickering emulsion; then, drop 1mL of three Butylamine was reacted under the catalysis of amine for 10 minutes to obtain microcapsules coated with vinyl repair agent, washed with distilled water, filtered through a Buchner funnel, and dried in air to obtain dry microcapsules coated with vinyl repair agent.

Embodiment 2

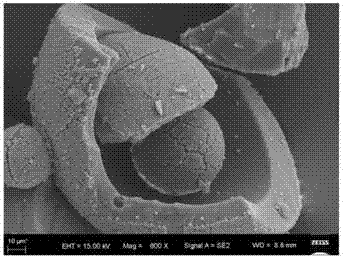

[0029] Embodiment 2: the preparation of encapsulating ethylenic restorative agent microcapsules

[0030] Mix 0.5g trimethylolpropane tris(3-mercaptopropionate), 0.42g isophorone diisocyanate and 2.14g glycidyl methacrylate to form an oil phase, and mix 0.75g SiO 2 The particles were added to 15g of water and stirred to disperse evenly to form a water phase. Add the obtained oil phase and water phase into a three-necked flask equipped with a stirrer, start stirring and control the rotation speed at 2000rpm, stir for 10min to obtain an oil-in-water Pickering emulsion; then, drop 1.5mL of Tributylamine, reacted under the catalysis of amine for 10min to obtain the microcapsules coated with ethylenic repair agent, washed with distilled water, filtered through Buchner funnel, and dried in air to obtain dry microcapsules coated with ethylenic repair agent .

Embodiment 3

[0031] Embodiment 3: the preparation of encapsulating ethylenic restorative agent microcapsules

[0032] Mix 0.5g trimethylolpropane tris(3-mercaptopropionate), 0.42g isophorone diisocyanate and 2.14g tripropylene glycol diacrylate to form an oil phase, and mix 0.05g SiO 2 The particles were added to 10g of water and stirred to disperse evenly to form a water phase. Add the obtained oil phase and water phase into a three-neck flask equipped with a stirrer, start stirring and control the rotation speed at 1000rpm, stir for 10min to obtain an oil-in-water Pickering emulsion; then, drop 0.5mL of N,N-Dimethylacetamide reacted under the catalysis of amines for 10 minutes to obtain microcapsules coated with olefin repair agents, washed with distilled water, filtered through a Buchner funnel, and dried in air to obtain dry coated olefins. Microcapsules of restorative agents.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com