Control method for large-scale preparation of phase change capsules based on microfluidics

A phase change capsule and control method technology, applied in microcapsule preparations, microsphere preparation, chemical instruments and methods, etc., can solve problems such as low efficiency and poor integration of experimental devices, and achieve simplified preparation process, large application potential, and saving effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

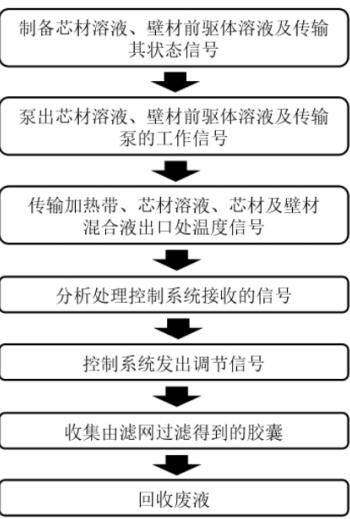

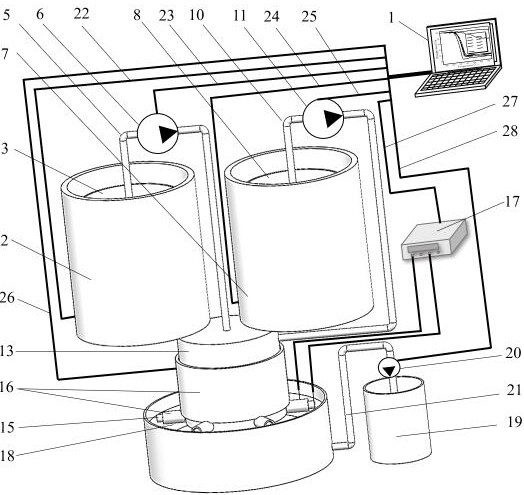

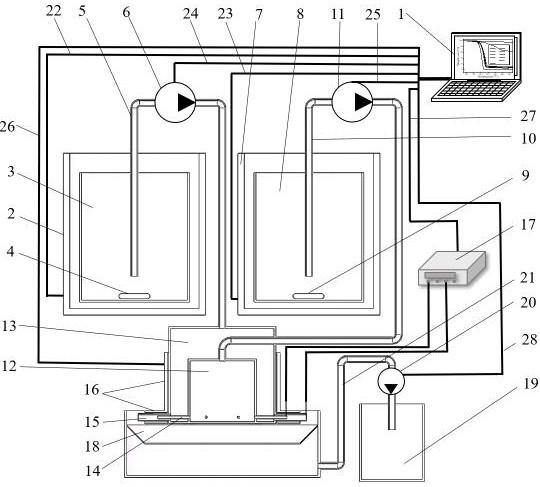

[0040] A control method for large-scale production of phase change capsules, such as figure 2 , 3 As shown, the devices involved in the control method include a control system 1, an intelligent water bath magnetic stirrer, a micro liquid pump, a heating belt 16, a thermocouple thermometer 17, a core material container and its circulation pipeline, a wall material container and Its circulation pipeline, filter screen 18, waste liquid containing container 19, a plurality of connecting wires; Figure 4 As shown, the method may include:

[0041] S1: add the core material component with trigger and emulsifier, and the wall material component with precursor and acid-base environment adjusting substance into the core material solution container 3 and the wall material solution container 8 respectively, and set the first A heating and stirring device 2 and a second heating and stirring device 7 work parameters to heat and stir the core material component and the wall material compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com