Novel buckle-type split plunger pump oblique disc variable adjusting mechanism and method

A variable adjustment, plunger pump technology, applied in valve details, mechanical equipment, engine components, etc., can solve problems affecting the reliability and life of swash plate axial plunger pumps, poor local structural stress, installation, debugging and assembly. Difficulty and other problems, to achieve the effect of reducing the difficulty of processing technology and installation and debugging, improving variable control performance, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

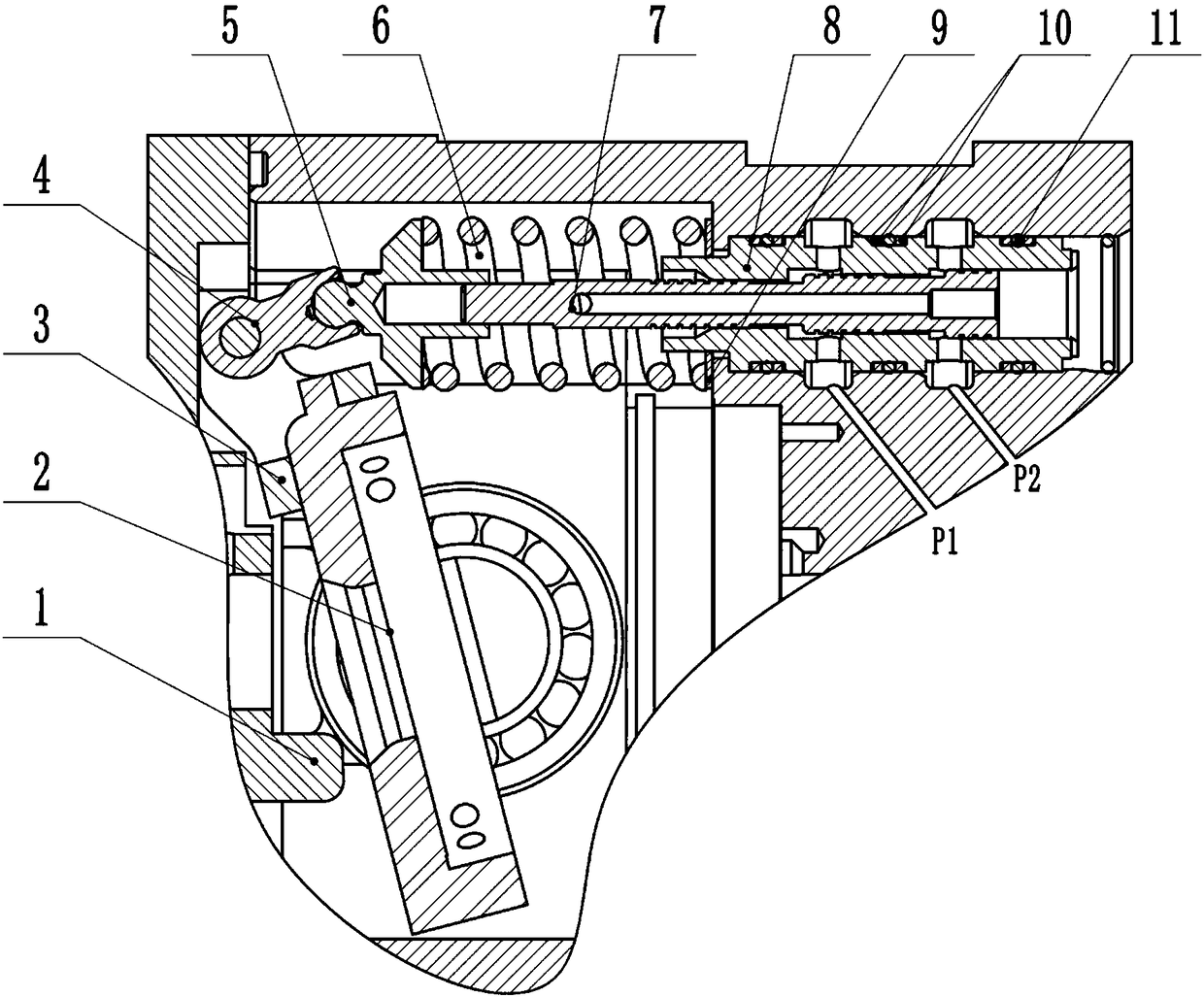

[0030] Such as figure 1 As shown, the present invention provides a novel buckle type split plunger pump swash plate variable adjustment mechanism, including swash plate body 2, snap connection seat 3, hinged connecting rod 4, variable adjustment guide seat 5, variable spring 6 , variable spool 7, valve sleeve 8, spring retainer 9, retaining ring 10 and O-ring 11;

[0031] The swash plate body 2 is installed on the bearing seat of the plunger pump casing 1 through the deep groove ball bearings at the trunnions at both ends;

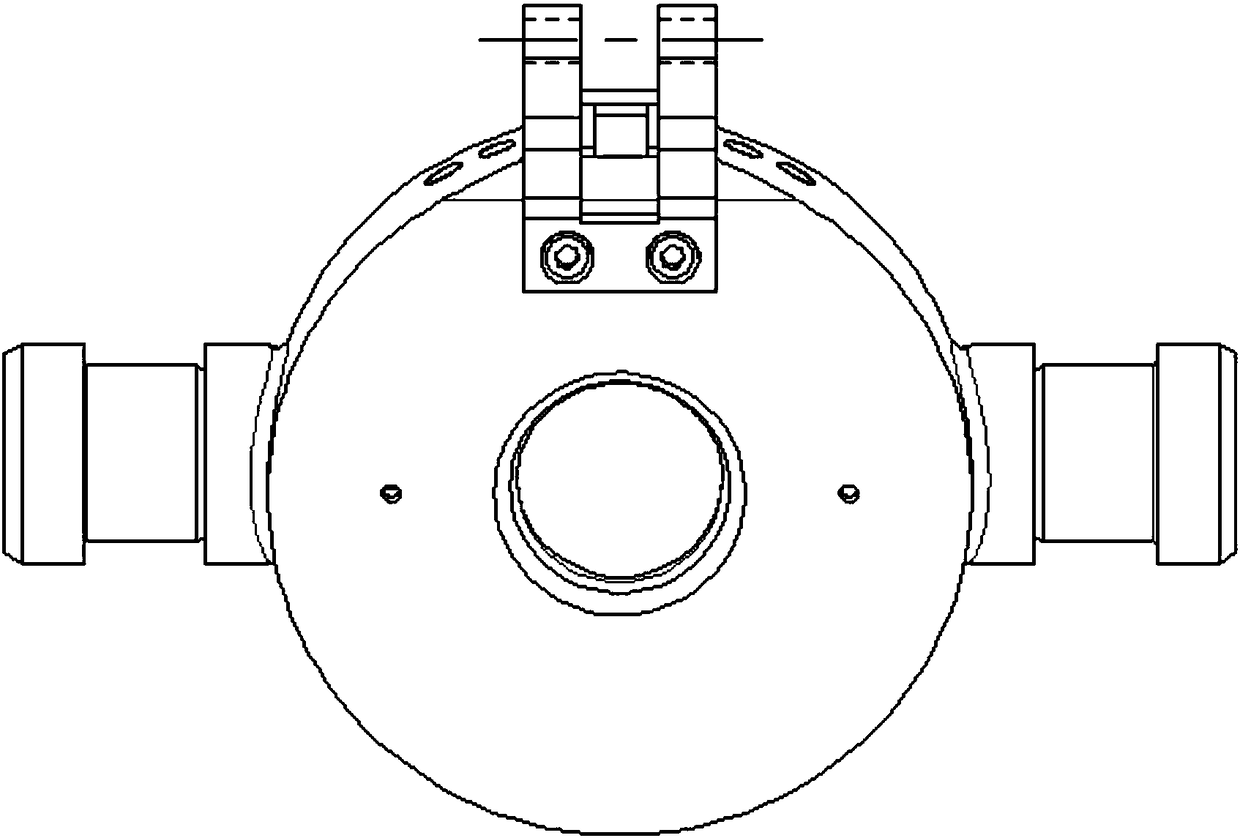

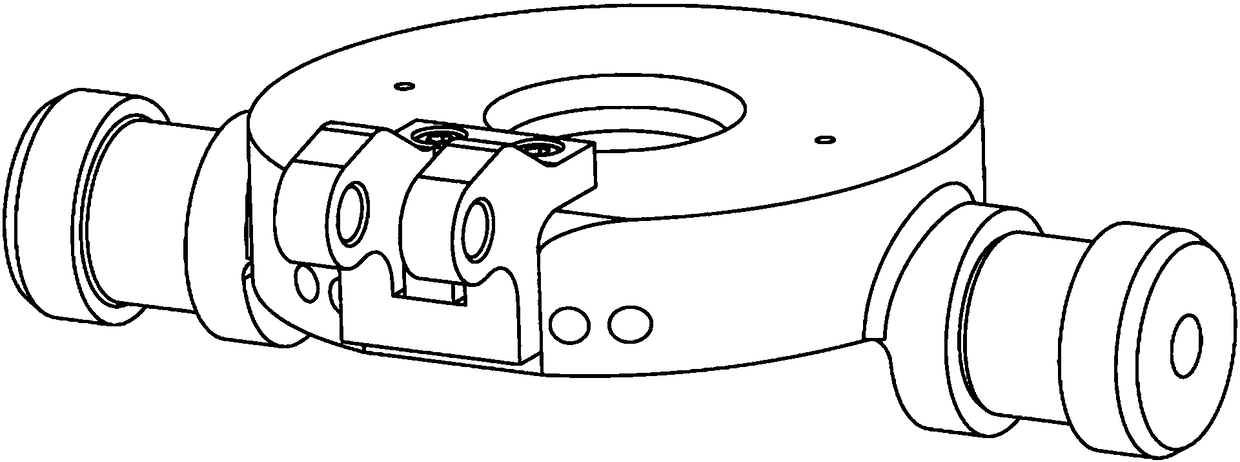

[0032] The buckle connection seat 3 is fixedly connected with the swash plate body 2; figure 2 , 3 The preferred structure shown is specifically: a plane is set on the peripheral surface of the swash plate body 2 as the installation surface, and a rectangular protrusion is set on the plane; the cross-section o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com