Combined heat and power generation full-condensation afterheat recovery technology

A waste heat recovery and cogeneration technology, applied in heating methods, preheating, heating fuels, etc., can solve the problems of energy waste, low-grade cooling water waste heat that cannot be used and consumed, and achieve the effect of recycling waste heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

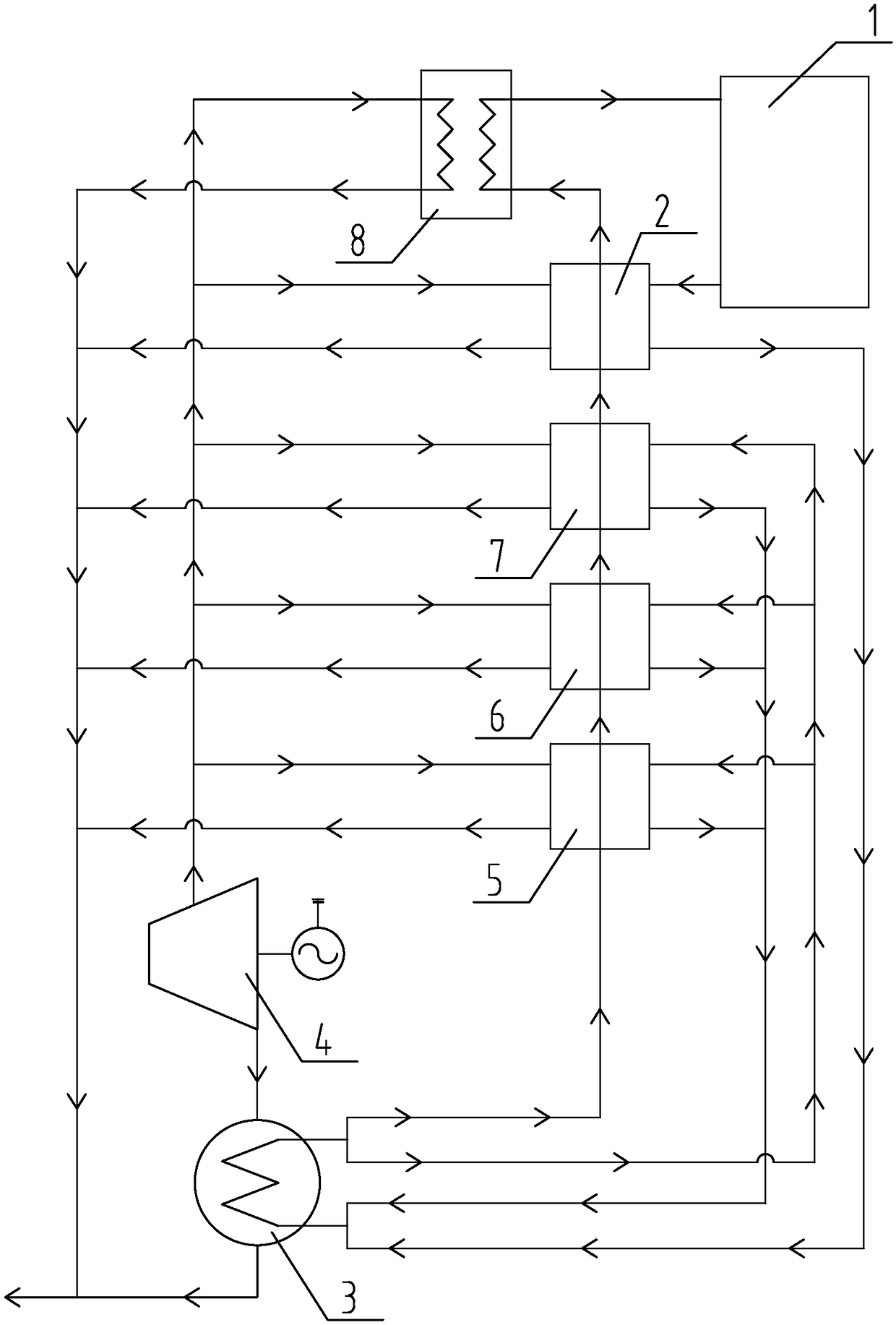

[0026] The return water from the primary network of the heating station 1 is transported back to the thermal power plant. After the return water enters the absorption heat pump 2 for adjusting the temperature of the meeting water, it is used as a low-temperature heat source. After being absorbed, the temperature is further reduced and adjusted to the temperature suitable for the cooling water of the condenser 3.

[0027] The cooling water after work in the condenser 3 is discharged from the outlet of the condenser 3, and is divided into two parts at the same time, most of which are used as low-temperature heat sources for the first-stage absorption heat pump 5, the second-stage absorption heat pump 6, and the third-stage absorption heat pump 7 , a small part is used as the primary network water supply, through the first-stage absorption heat pump 5, the second-stage absorption heat pump 6, and the third-stage absorption heat pump 7, to carry out stage-by-stage heating.

[0028]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com