Bearing state online monitoring system and method based on optical fiber vibration sensing

A monitoring system, optical fiber vibration technology, applied in the direction of mechanical bearing testing, etc., can solve the problems of increasing system cost, laser loss, etc., to achieve good sensitivity, reduce power, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

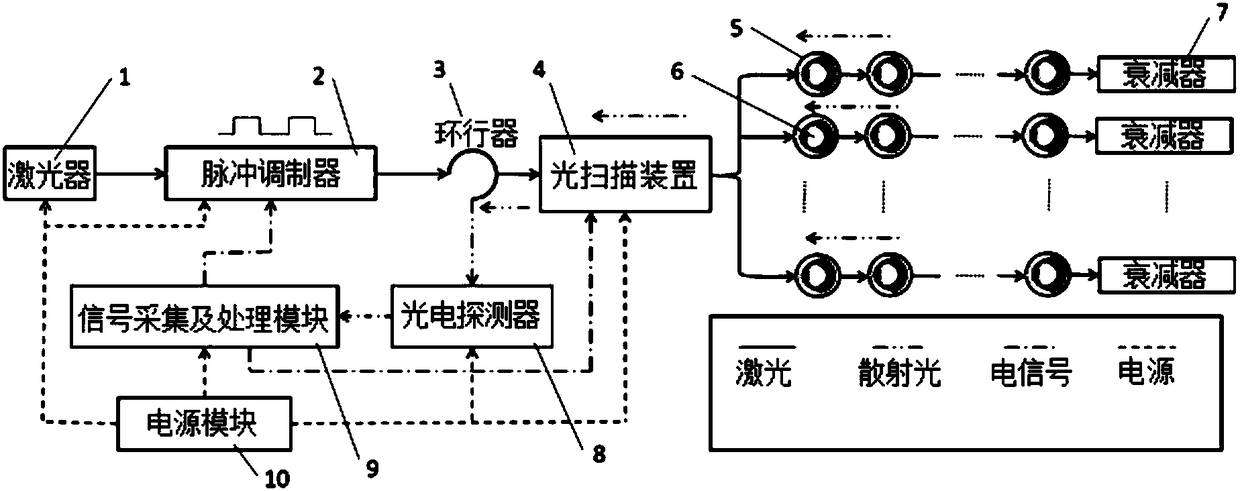

[0038] refer to figure 1 , an on-line monitoring system for bearing status based on optical fiber vibration sensing (hereinafter, sometimes simply referred to as "monitoring system") according to an embodiment of the present invention includes a laser 1, a pulse modulator 2, a circulator 3, an optical scanning device 4, a vibration Sensing optical cable 5 , attenuator 7 , photodetector 8 , signal acquisition and processing module 9 and power module 10 .

[0039] After the laser light produced by the laser 1 is modulated into pulsed laser light by the pulse modulator 2, it enters a vibration sensing optical cable 5 among a plurality of (n) vibration sensing optical cables 5 through a circulator 3 and an optical scanning device 4 to detect multiple ( m) the vibration of the bearing 6 under working conditions. The vibration of the bearing 6 will cause the stress of the optical fiber in the vibration sensing optical cable 5 to change, thereby causing the corresponding change of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com