Finished PCB online maintenance equipment and maintenance method

A PCB board and wiring technology, which is applied in the field of automatic PCB finished product maintenance and wiring equipment and maintenance, can solve the problems of high probability of misoperation, difficult management, and low accuracy, so as to reduce the number of times of back and forth handling, improve processing efficiency and Speed, the effect of increasing the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

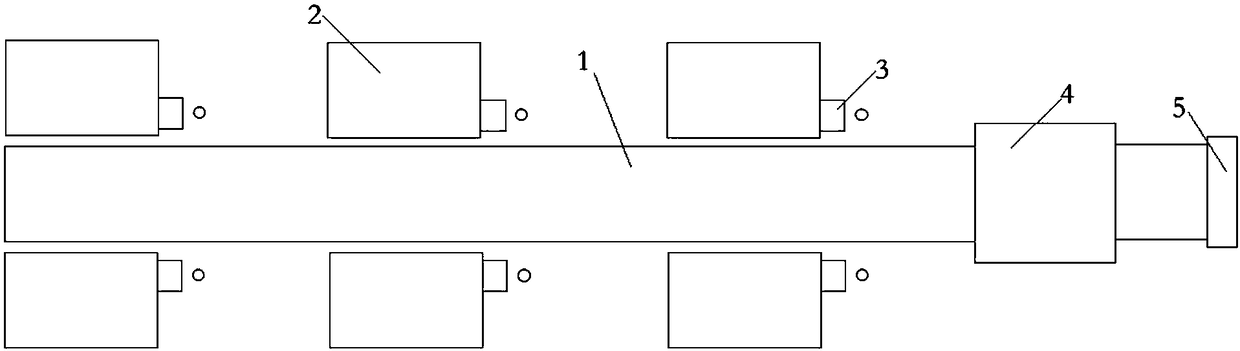

[0030] This embodiment provides a PCB finished product inspection and repair wiring device, which is used for inspecting the appearance of the finished PCB board and repairing the PCB with abnormal appearance, so as to improve product quality.

[0031] The PCB finished product inspection and wiring equipment such as figure 1 As shown, it includes a PCB transmission mechanism 1, the PCB transmission mechanism 1 is used to transmit the PCB board to be overhauled and overhauled, and the PCB transmission mechanism 1 is a set of transmission rollers or an automatic conveyor belt, which moves the PCB board along the The length direction of the PCB transmission mechanism 1 is transmitted from the input end to the output end of the PCB transmission mechanism 1 .

[0032] Both sides of the PCB transmission mechanism 1 are respectively provided with a number of automatic appearance inspection machines 2, and the automatic appearance inspection machines 2 are distributed along the length...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com