Producing execution system

A manufacturing execution system and production data technology, applied in the field of manufacturing, can solve the problems of digitization of the production process, difficulties in transparent management, lack of production execution management system, and timely feedback of production process information, so as to reduce the amount of data storage and ensure Reliability, the effect of reducing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below with reference to the accompanying drawings and examples.

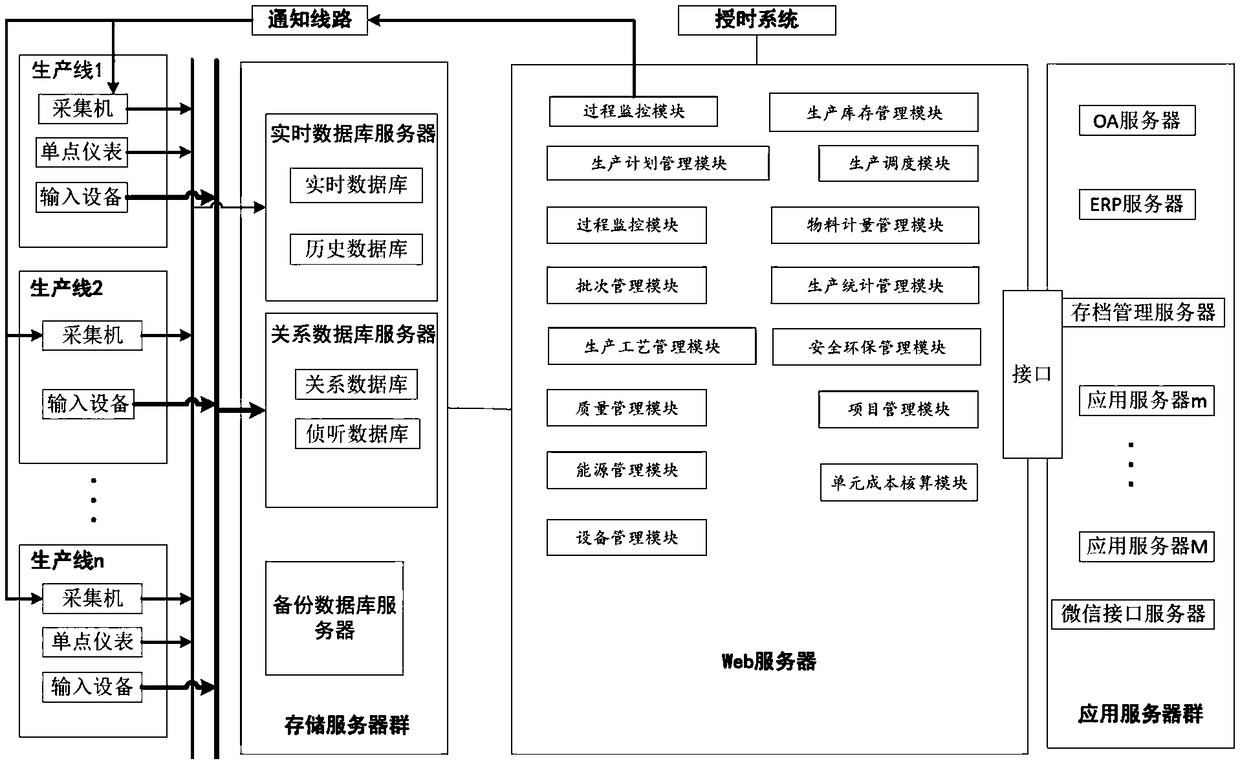

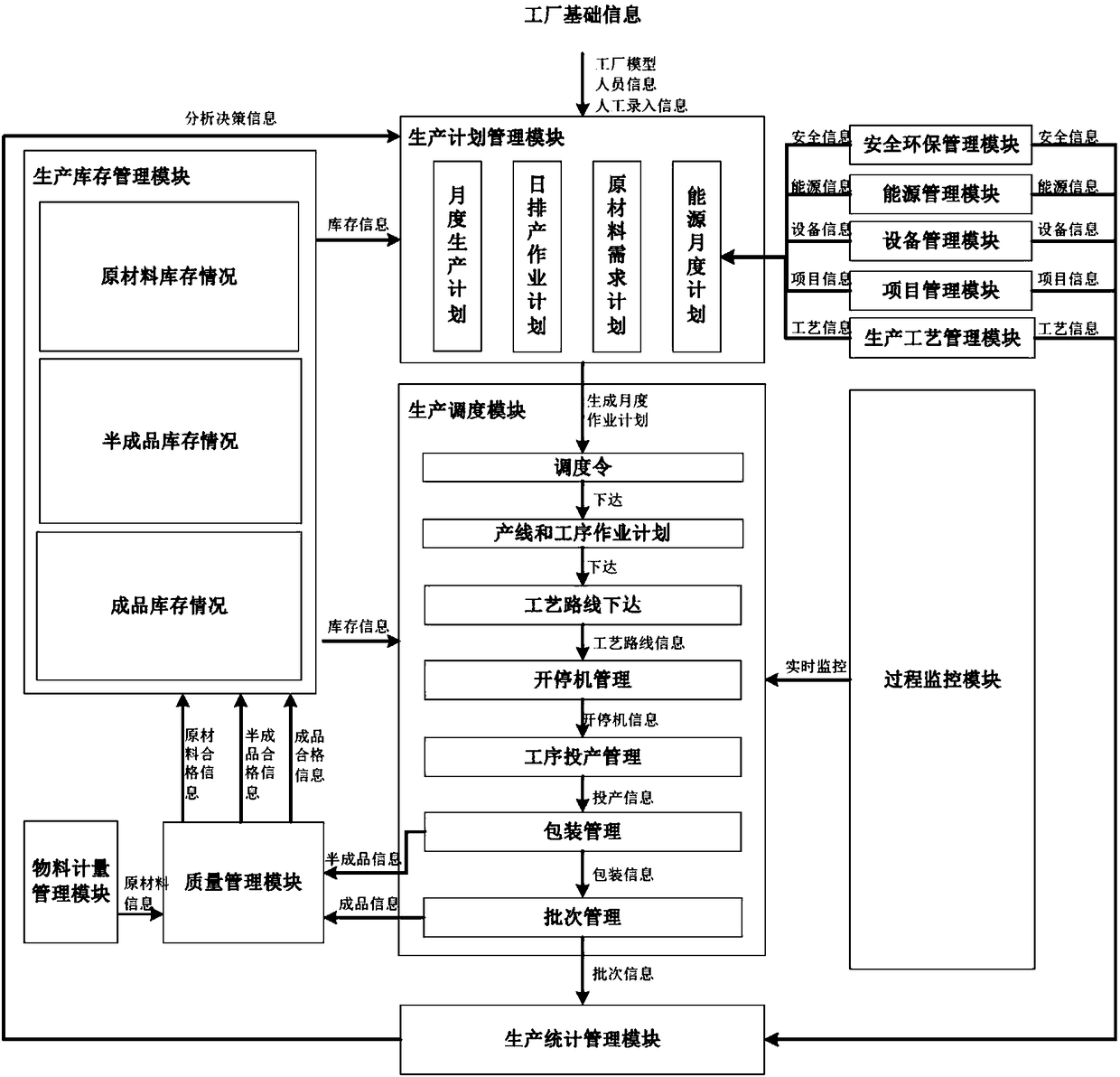

[0047] The invention provides a manufacturing execution system for the production of dangerous goods, such as figure 1 As shown, the system includes an acquisition subsystem, a storage server group, a time service system, a Web server, a service server group and a notification line. Each module is described in detail below.

[0048] (1) Timing system

[0049] The timing system provides system time for the components of this MES. The system time is the time base of this system. When the components in the system need time synchronization, they all rely on the system time provided by this module to complete.

[0050] (2) Acquisition subsystem

[0051] The data to be collected by the acquisition subsystem includes real-time production data, single-point production data and weighing instrument data.

[0052] Among them, the real-time production data refer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com