Middle-sized domestic waste treatment device

A technology of domestic waste and treatment device, applied in the field of waste treatment and environmental protection, can solve the problems of lack of popularity, low efficiency, and increased difficulty in waste treatment, and achieve the effect of improving speed and efficiency, efficient treatment and efficiency improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

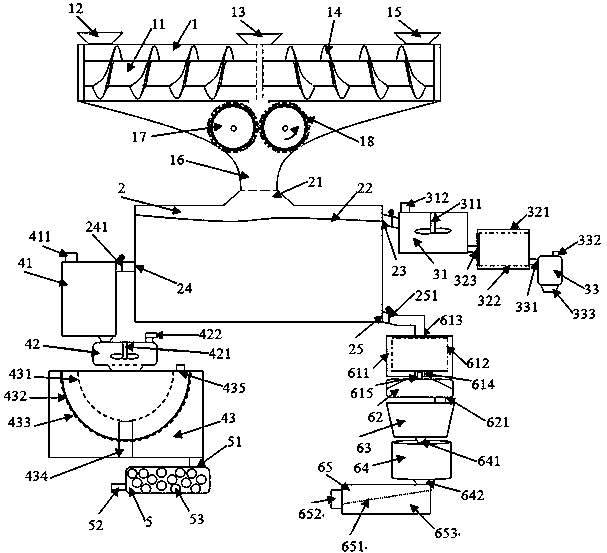

[0040] A medium-sized domestic waste treatment device, including a crushing chamber, a sedimentation tank, a decomposition chamber, a first separation chamber, an incineration chamber, a disinfection chamber, an acidification chamber, a centrifugal filter chamber, an adsorption chamber, a second separation chamber, a drying chamber, and a magnetic separation chamber. chamber, roasting chamber and sliding filter chamber.

[0041] The crushing chamber includes a crushing chamber casing, a first crushing shaft, a second crushing shaft, a first material inlet, a water inlet, a second material inlet, an outlet of the crushing chamber, and a roller; the first crushing shaft and the second The two crushing shafts are arranged axially opposite to each other on the top of the shell of the crushing cavity, and the first crushing blade and the second crushing blade are spirally arranged on the first crushing shaft and the second crushing shaft respectively, and the first crushing blade an...

Embodiment 2

[0067] A medium-sized domestic waste treatment device, including a crushing chamber, a sedimentation tank, a decomposition chamber, a first separation chamber, an incineration chamber, a disinfection chamber, an acidification chamber, a centrifugal filter chamber, an adsorption chamber, a second separation chamber, a drying chamber, and a magnetic separation chamber. chamber, roasting chamber and sliding filter chamber.

[0068] The crushing chamber includes a crushing chamber casing, a first crushing shaft, a second crushing shaft, a first material inlet, a water inlet, a second material inlet, an outlet of the crushing chamber, and a roller; the first crushing shaft and the second The two crushing shafts are arranged axially opposite to each other on the top of the shell of the crushing cavity, and the first crushing blade and the second crushing blade are spirally arranged on the first crushing shaft and the second crushing shaft respectively, and the first crushing blade an...

Embodiment 3

[0091] A medium-sized domestic waste treatment device, including a crushing chamber, a sedimentation tank, a decomposition chamber, a first separation chamber, an incineration chamber, a disinfection chamber, an acidification chamber, a centrifugal filter chamber, an adsorption chamber, a second separation chamber, a drying chamber, and a magnetic separation chamber. chamber, roasting chamber and sliding filter chamber.

[0092] The crushing chamber includes a crushing chamber casing, a first crushing shaft, a second crushing shaft, a first material inlet, a water inlet, a second material inlet, an outlet of the crushing chamber, and a roller; the first crushing shaft and the second The two crushing shafts are arranged axially opposite to each other on the top of the shell of the crushing cavity, and the first crushing blade and the second crushing blade are spirally arranged on the first crushing shaft and the second crushing shaft respectively, and the first crushing blade an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com