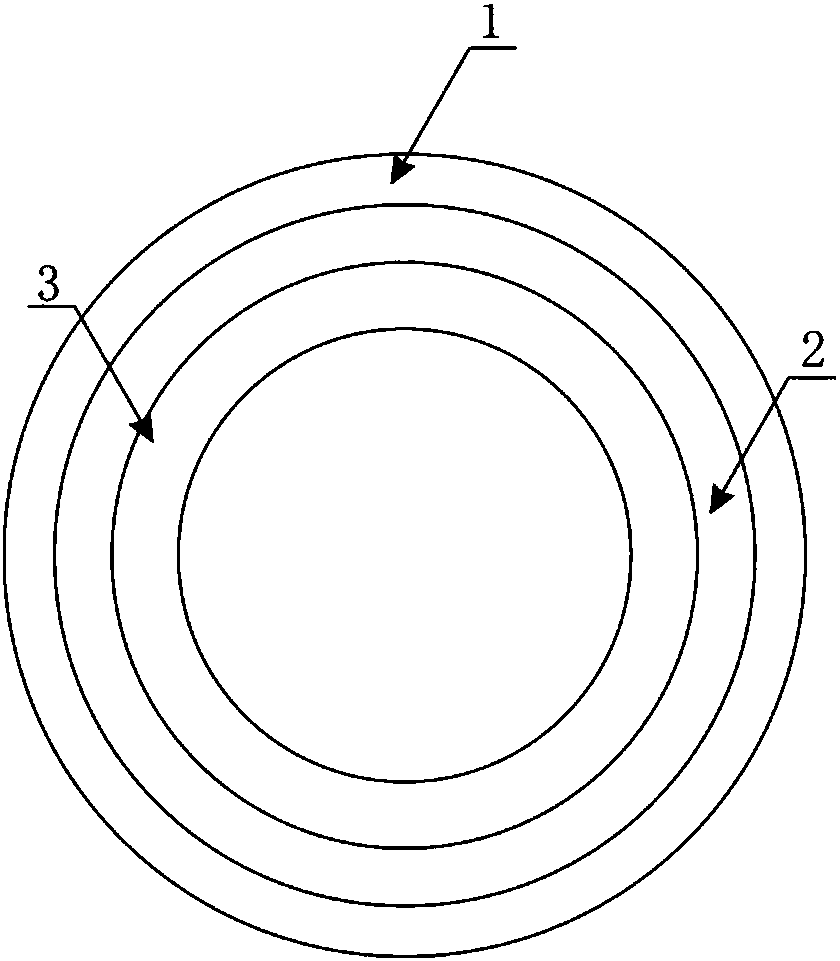

Multi-layer lightweight RPC (Reactive Powder Concrete) electric pole and manufacturing method thereof

A multi-layer, electric pole technology, applied in the field of power transmission and transformation projects, can solve the problems of short service life, weak resistance, insufficient strength of electric poles, etc., and achieve the goal of improving corrosion resistance, increasing service life, and promoting construction and transformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for preparing a multi-layer lightweight RPC pole, comprising the following steps:

[0036] (1) Put the RPC cloth into the pipe mold, clean and close the mold after the cloth is completed;

[0037] (2) Centrifuge at 50r / min for 300s, then centrifuge at 1000r / min for 240s to obtain an outer protective layer with a thickness of 5mm;

[0038] (3) After the outer protective layer of the pole is centrifugally formed, use RPC as the raw material, add steel fibers accounting for 3% of its volume to it, stir, and then use the high-pressure concrete pump to pump the material in the outer protective layer , after the fabric is finished, carry out the centrifugal forming of the core layer, wherein, the centrifugation condition is: centrifuge at 50r / min for 30s, and then centrifuge at 1000r / min for 240s to obtain a core layer with a thickness of 15mm;

[0039] (4) After the core layer of the pole is centrifugally formed, the inner protective layer of the pole needs to be s...

Embodiment 2

[0042]A method for preparing a multi-layer lightweight RPC pole, comprising the following steps:

[0043] (1) Put the RPC cloth into the pipe mold, clean and close the mold after the cloth is completed;

[0044] (2) Centrifuge at 100r / min for 150s, then centrifuge at 600r / min for 150s to obtain an outer protective layer with a thickness of 5mm;

[0045] (3) After centrifugally forming the outer protective layer of the pole, use RPC as the raw material, add steel fibers accounting for 4% of its volume to it, stir, and then use the high-pressure concrete pump to pump the material in the outer protective layer , after the fabric is finished, carry out the centrifugal molding of the core layer, wherein, the centrifugation condition is: centrifuge at 100r / min for 100s, and then centrifuge at 800r / min for 150s to obtain a core layer with a thickness of 30mm;

[0046] (4) After the outer protective layer and the core layer are formed, let stand for 6h, then raise the temperature to ...

Embodiment 3

[0048] A method for preparing a multi-layer lightweight RPC pole, comprising the following steps:

[0049] (1) Put the RPC cloth into the pipe mold, clean and close the mold after the cloth is completed; and centrifuge at 120r / min for 60s, and then centrifuge at 300r / min for 480s to obtain an outer protective layer with a thickness of 5mm;

[0050] (2) After centrifugally forming the outer protective layer of the pole, use RPC as the raw material, add steel fibers accounting for 2% of its volume to it, stir, and then use the high-pressure concrete pump to pump the material in the outer protective layer , after the fabric is finished, carry out the centrifugal molding of the core layer, wherein, the centrifugation condition is: centrifuge 180s under 120r / min, then centrifuge 360s under 300r / min, obtain the core layer that thickness is 25mm;

[0051] (4) After the core layer of the pole is centrifugally formed, the inner protective layer of the pole needs to be set, and the RPC ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com