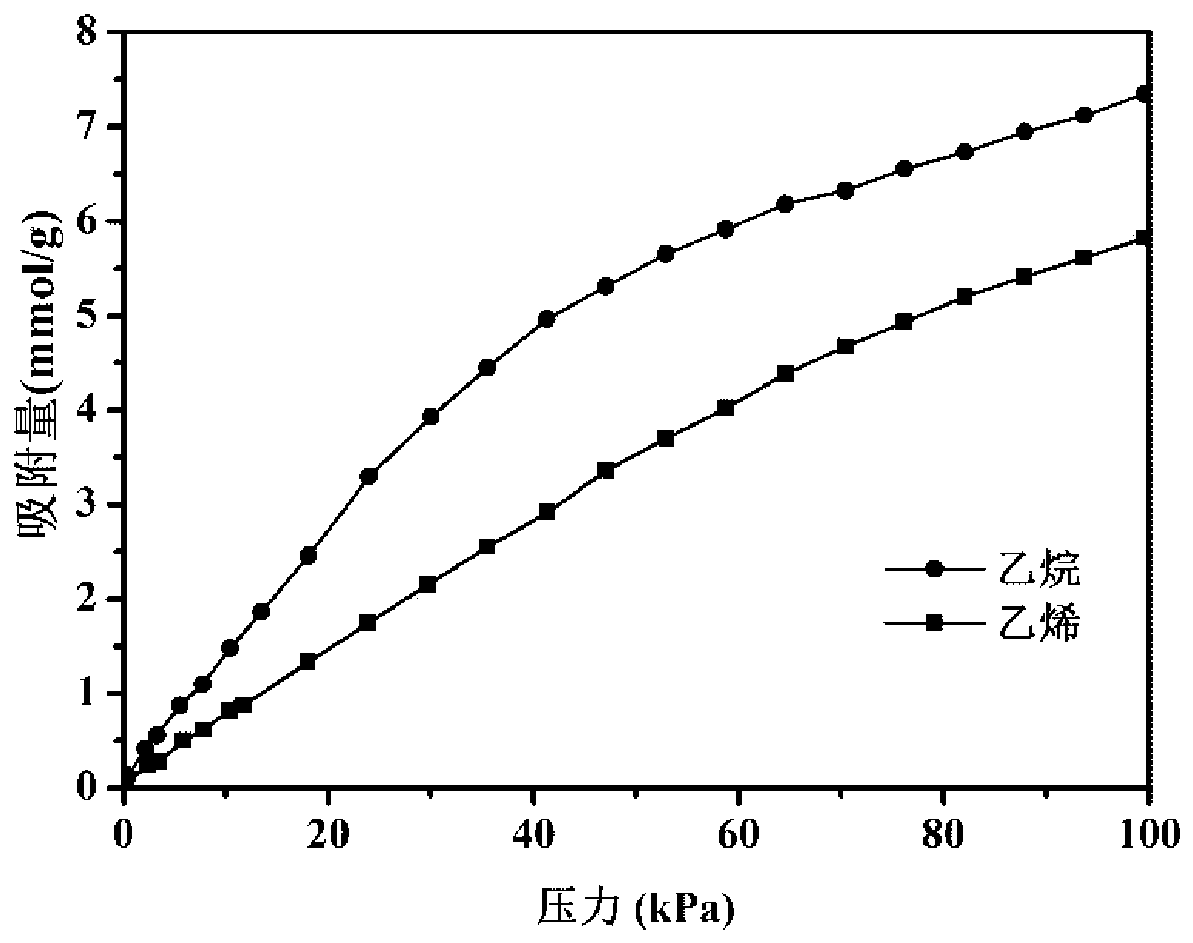

An iron-based double-ligand metal-organic framework material that preferentially adsorbs ethane and its preparation method and application

A metal organic framework, preferential adsorption technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of poor ethane/ethylene adsorption selectivity, easy structure collapse, low ethane ethylene adsorption capacity, etc. Good water vapor stability and efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

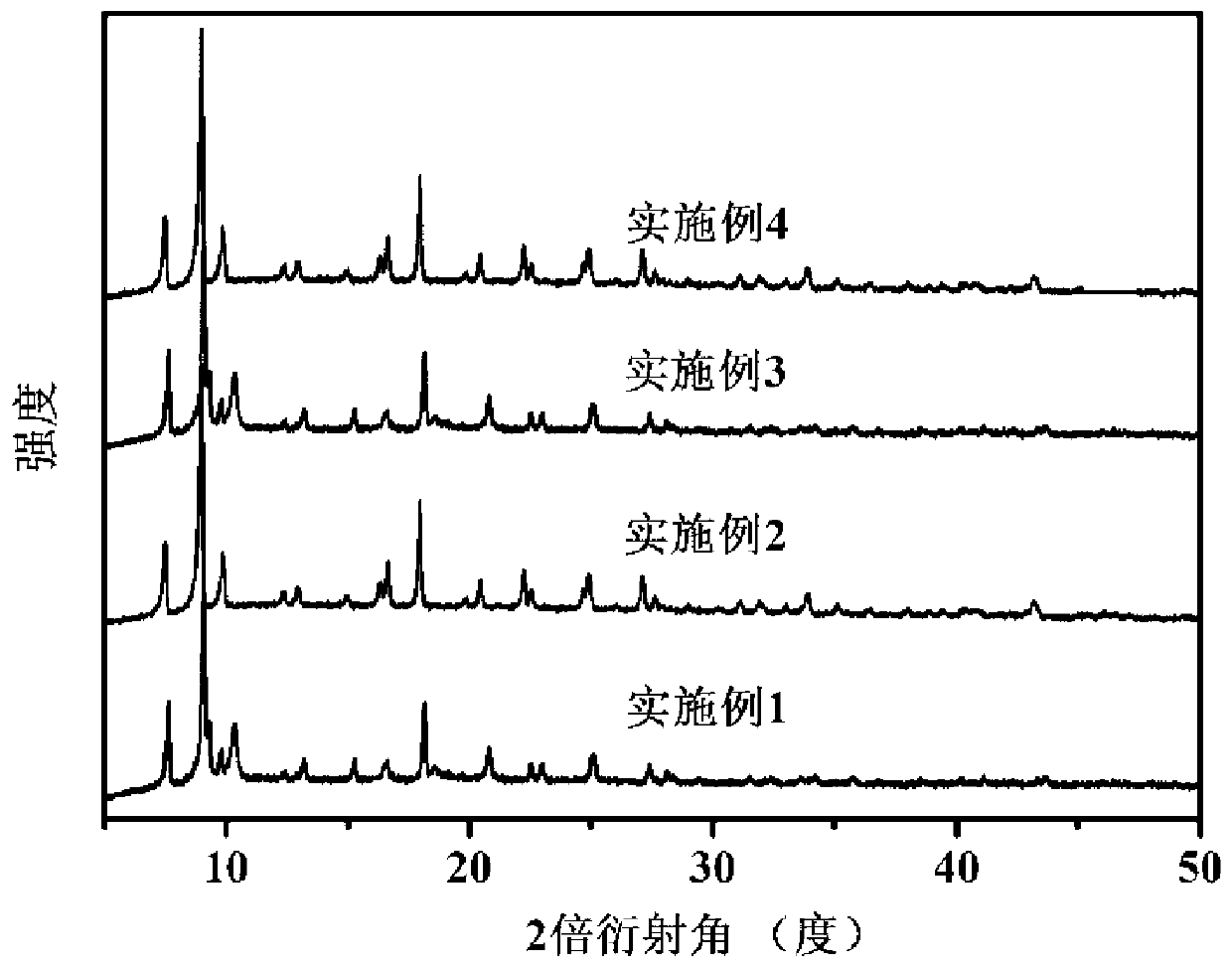

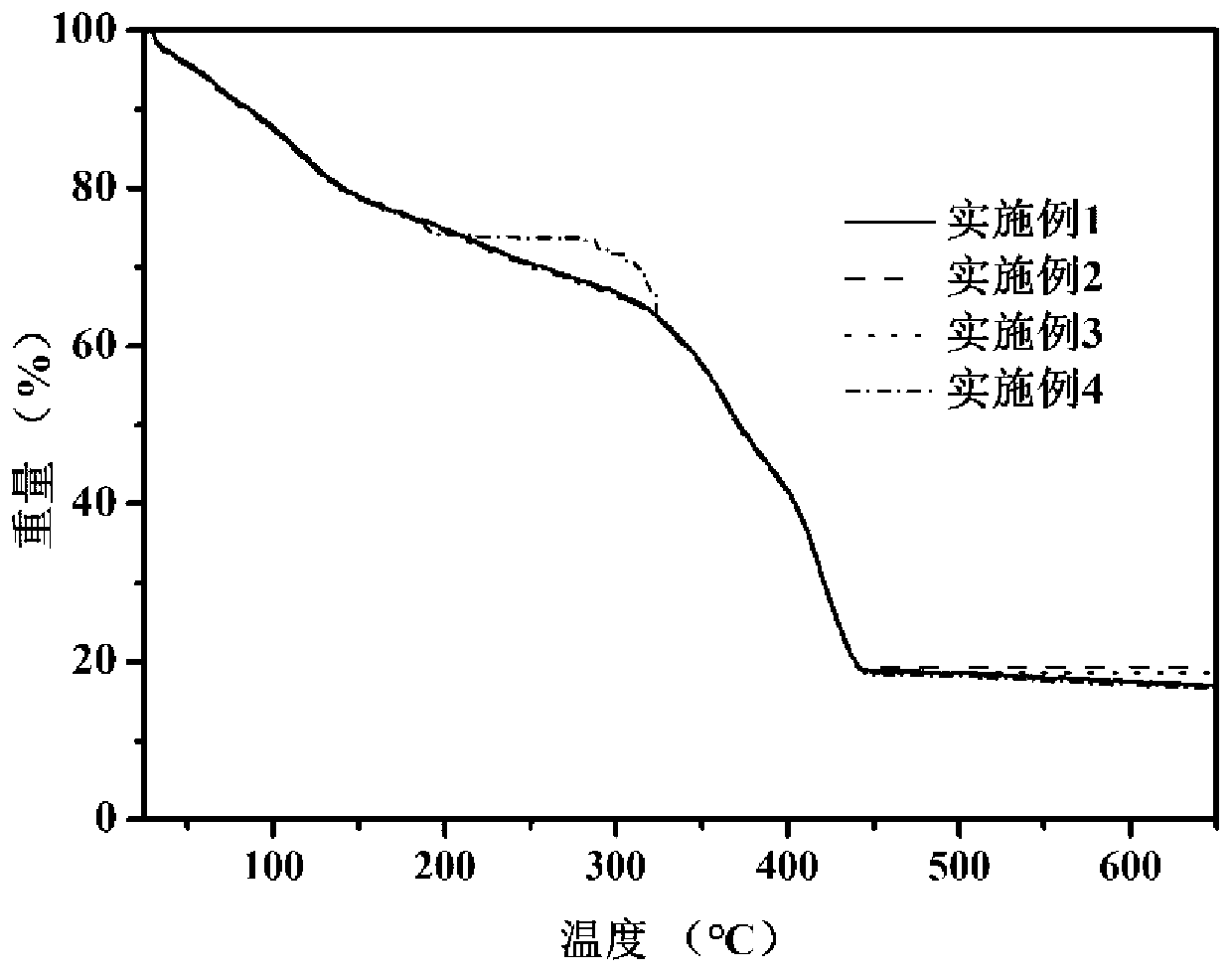

Embodiment 1

[0034] (1) Synthesis of iron clusters: 25.4262 g of anhydrous sodium acetate and 8.08 g of Fe(NO 3 ) 3 9H 2 O was dissolved in 50mL water respectively to obtain sodium acetate solution and ferric nitrate solution; then the sodium acetate solution was dropped dropwise into the ferric nitrate solution, and stirred for 12 hours to form a suspension; then the suspension was suction filtered to obtain a reddish-brown solid, and washed with 50 mL of deionized water and 50 mL of ethanol in turn, and finally put the product in a vacuum oven at 70 °C for 12 h at constant temperature to obtain iron clusters [Fe 3 (CH 3 COO) 6 ].

[0035] (2) Synthesis of iron-based double-ligand metal-organic framework materials: 60 mg terephthalic acid and 33 mg triethylenediamine were dissolved in 5 mL DMF to form a mixed solution; 10 1 mL of DMF solution in which 242 mg of iron clusters were dissolved was added dropwise to 1.525 mg of glacial acetic acid, and stirred for 30 min until the mixture...

Embodiment 2

[0037] (1) Synthesis of iron clusters: 25.4262 g of anhydrous sodium acetate and 8.08 g of Fe(NO 3 ) 3 9H 2 O was dissolved in 50mL water respectively to obtain sodium acetate solution and ferric nitrate solution; then the sodium acetate solution was dropped dropwise into the ferric nitrate solution, and stirred for 12 hours to form a suspension; then the suspension was suction filtered to obtain a reddish-brown solid, and washed with 50 mL of deionized water and 50 mL of ethanol in turn, and finally put the product in a vacuum oven at 70 °C for 12 h at constant temperature to obtain iron clusters [Fe 3 (CH 3 COO) 6 ].

[0038] (2) Synthesis of iron-based double-ligand MOFs: 53.375 mg of terephthalic acid and 27.45 mg of triethylenediamine were dissolved in 5 mL of DMF to form a mixed solution; 10 DMF solution in which 228.75 mg of iron clusters were dissolved was added dropwise to 1.525 mg of glacial acetic acid, and stirred for 30 min until the mixture was uniform; The...

Embodiment 3

[0040] (1) Synthesis of iron clusters: 25.4262 g of anhydrous sodium acetate and 8.08 g of Fe(NO 3 ) 3 9H 2 O was dissolved in 50mL water respectively to obtain sodium acetate solution and ferric nitrate solution; then the sodium acetate solution was dropped dropwise into the ferric nitrate solution, and stirred for 12 hours to form a suspension; then the suspension was suction filtered to obtain a reddish-brown solid, and washed with 50 mL of deionized water and 50 mL of ethanol in turn, and finally put the product in a vacuum oven at 70 °C for 12 h at constant temperature to obtain iron clusters [Fe 3 (CH 3 COO) 6 ].

[0041] (2) Synthesis of iron-based double-ligand metal-organic framework materials: 68.625 mg of terephthalic acid and 36.6 mg of triethylenediamine were dissolved in 5 mL of DMF to form a mixed solution; 10 DMF solution in which 251.625 mg of iron clusters were dissolved was added dropwise to 1.525 mg of glacial acetic acid, and stirred for 30 min until ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com