High-strength aluminum-containing ferrite ODS steel and preparation method thereof

An aluminum ferrite, high-strength technology, applied in the field of composition design of new high-strength corrosion-resistant aluminum-containing ferrite ODS steel, can solve problems such as unfavorable mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

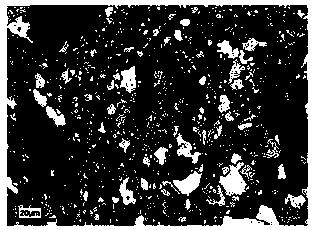

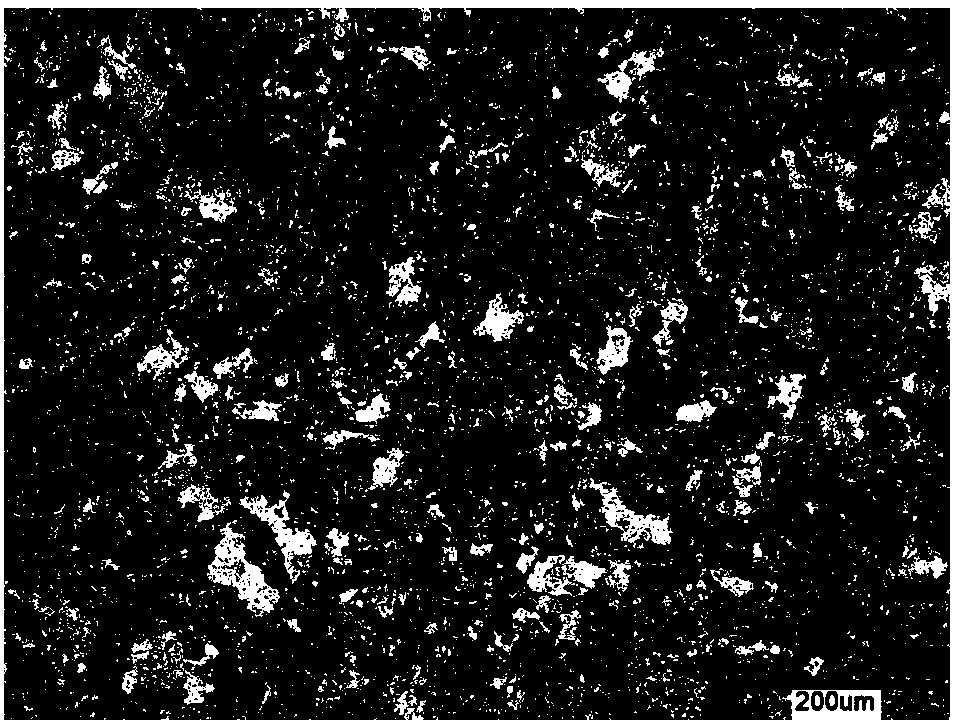

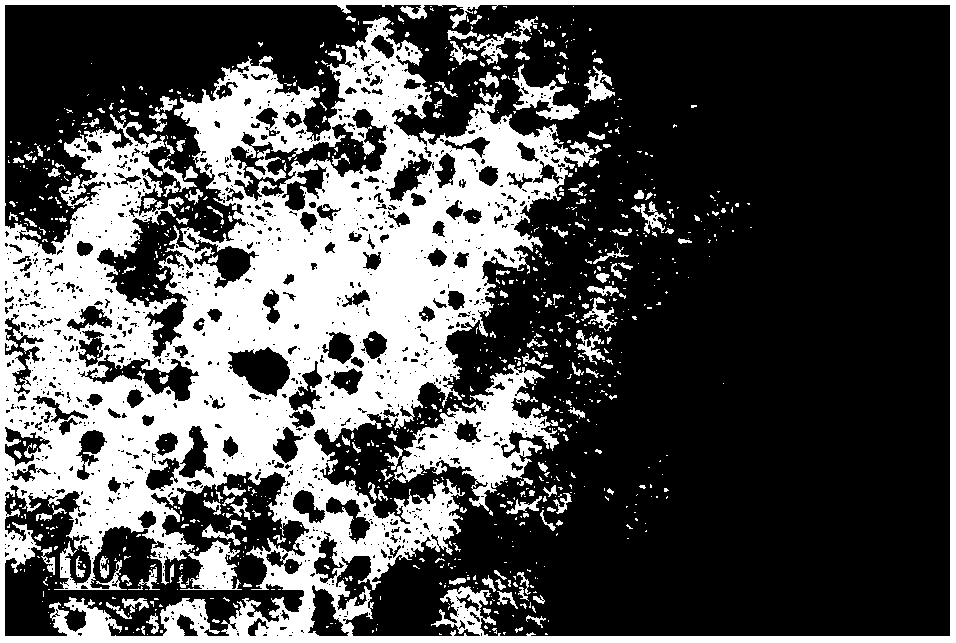

Image

Examples

Embodiment 1

[0037] First, the pre-alloyed powder (prepared by Tianjin Zhujin Science and Technology Development Co., Ltd.) whose composition is Fe-16wt%Cr-3wt%Al-1.5wt%W is prepared by gas atomization method, and 4 parts of pre-alloyed powder with a weight of 148.725g are weighed. Alloy powder is put into four 2000ml ball mill jars respectively. Then respectively add 0.525g (0.35wt%) particle diameter in 4 ball mill jars and be the Y of 40nm 2 o 3 Particles and 0.75g (0.5wt%) average diameter of 10 μm elemental Hf powder (Fe, Cr, Al, W, Y 2 o 3 The sum of Hf and Hf is the mass percent (100wt%). Then put 1500g stainless steel balls into 4 ball milling pots as the ball milling medium (ball-to-material ratio 10:1), wherein the weight ratio of steel balls with a diameter of 6mm and 10mm is 4:1. Then the ball milling tank with steel balls and powders was filled with argon in the glove box and sealed, so that the ball milling process was carried out under the environment of argon. The ball...

Embodiment 2

[0039] First prepare the pre-alloyed powder (prepared by Tianjin Zhujin Science and Technology Development Co., Ltd.) of Fe-22wt%Cr-1wt%Al-3wt%W with gas atomization method, and take 4 parts of pre-alloyed powder with a weight of 148.725g The powder is put into four 2000ml ball mill jars respectively. Then add 3wt% particle diameter to 4 ball mill jars respectively and be the Y of 40nm 2 o 3 Particles and 0.3wt% average diameter of 10 μm elemental Hf powder (Fe, Cr, Al, W, Y 2 o 3 The sum of Hf and Hf is the mass percent (100wt%). Then put 1500g stainless steel balls into 4 ball milling pots as the ball milling medium (ball-to-material ratio 10:1), wherein the weight ratio of steel balls with a diameter of 6mm and 10mm is 4:1. Then the ball milling tank with steel balls and powders was filled with argon in the glove box and sealed, so that the ball milling process was carried out under the environment of argon. The ball mill adopts the QM-2SP12 planetary high-energy ball ...

Embodiment 3

[0041] At first the prealloyed powder (prepared by Tianjin Zhujin Science and Technology Development Co., Ltd.) whose composition is Fe-14wt%Cr-6wt%Al-1wt%W is prepared by gas atomization method, and 4 parts of prealloyed powders with a weight of 148.725g are weighed The powder is put into four 2000ml ball mill jars respectively. Then add 0.3wt% to 4 ball mill jars respectively) particle diameter is the Y of 40nm 2 o 3 Particles and 1.0wt% average diameter of 10 μm elemental Hf powder (Fe, Cr, Al, W, Y 2 o 3 The sum of Hf and Hf is the mass percent (100wt%). Then put 1500g stainless steel balls into 4 ball milling pots as the ball milling medium (ball-to-material ratio 10:1), wherein the weight ratio of steel balls with a diameter of 6mm and 10mm is 4:1. Then the ball milling tank with steel balls and powders was filled with argon in the glove box and sealed, so that the ball milling process was carried out under the environment of argon. The ball mill adopts the QM-2SP12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com