Turnover stair construction plank road

A technology of plank roads and stairs, applied in the preparation of building components on site, construction, building construction, etc., can solve the problems of formwork displacement, safety insecurity, personnel falling, etc., and achieve reasonable design, easy disassembly and assembly, and flexible layout Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

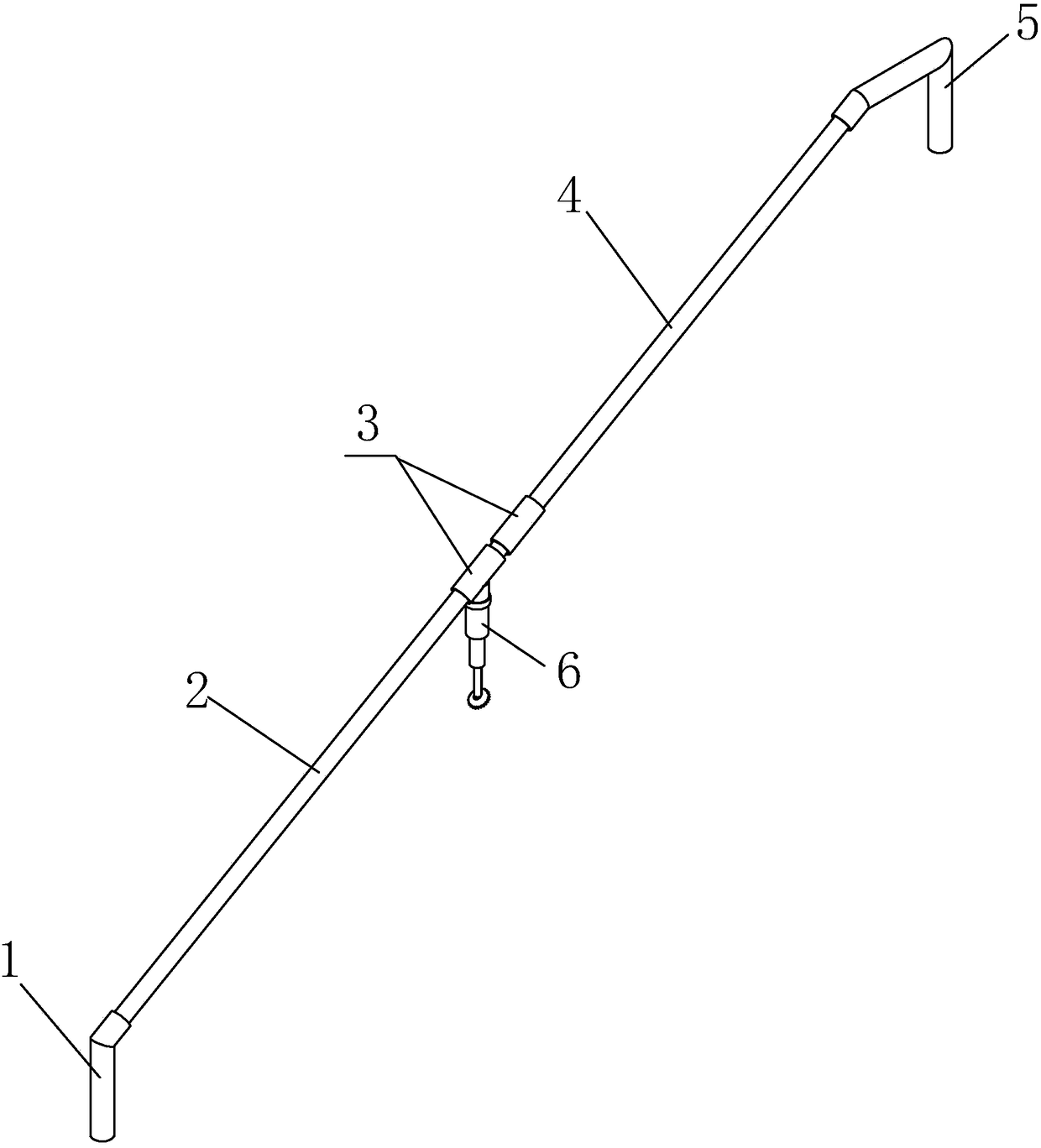

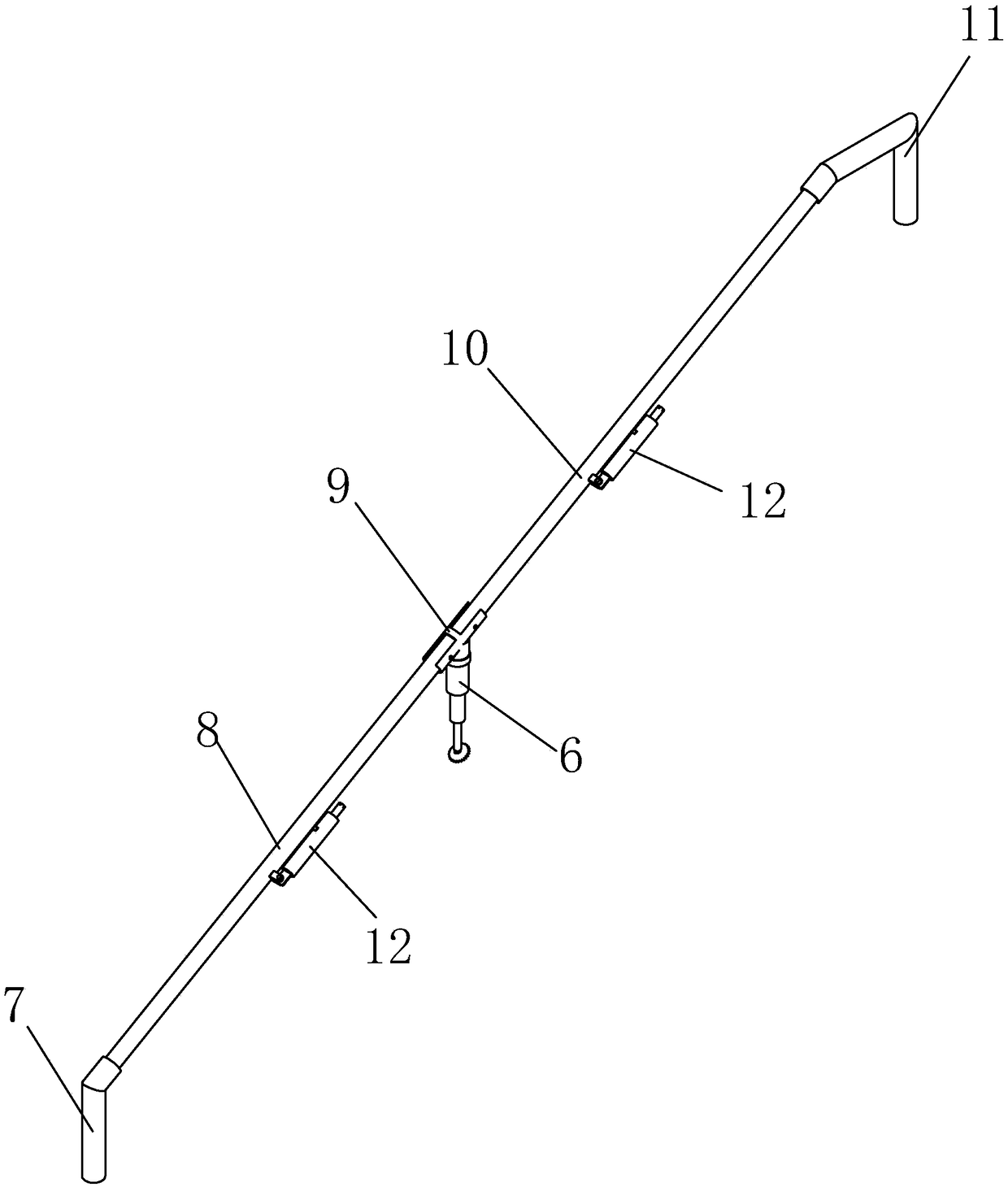

[0051] Such as Figure 1 to Figure 25 As shown, the reversible stair construction plank road (referred to as "plank road") of the present invention includes a rotatable main beam, a fixed main beam, an upper column I, an upper column II, a lower column I, a lower column II, a step bearing frame, Stair treads, anti-overturn bracing device.

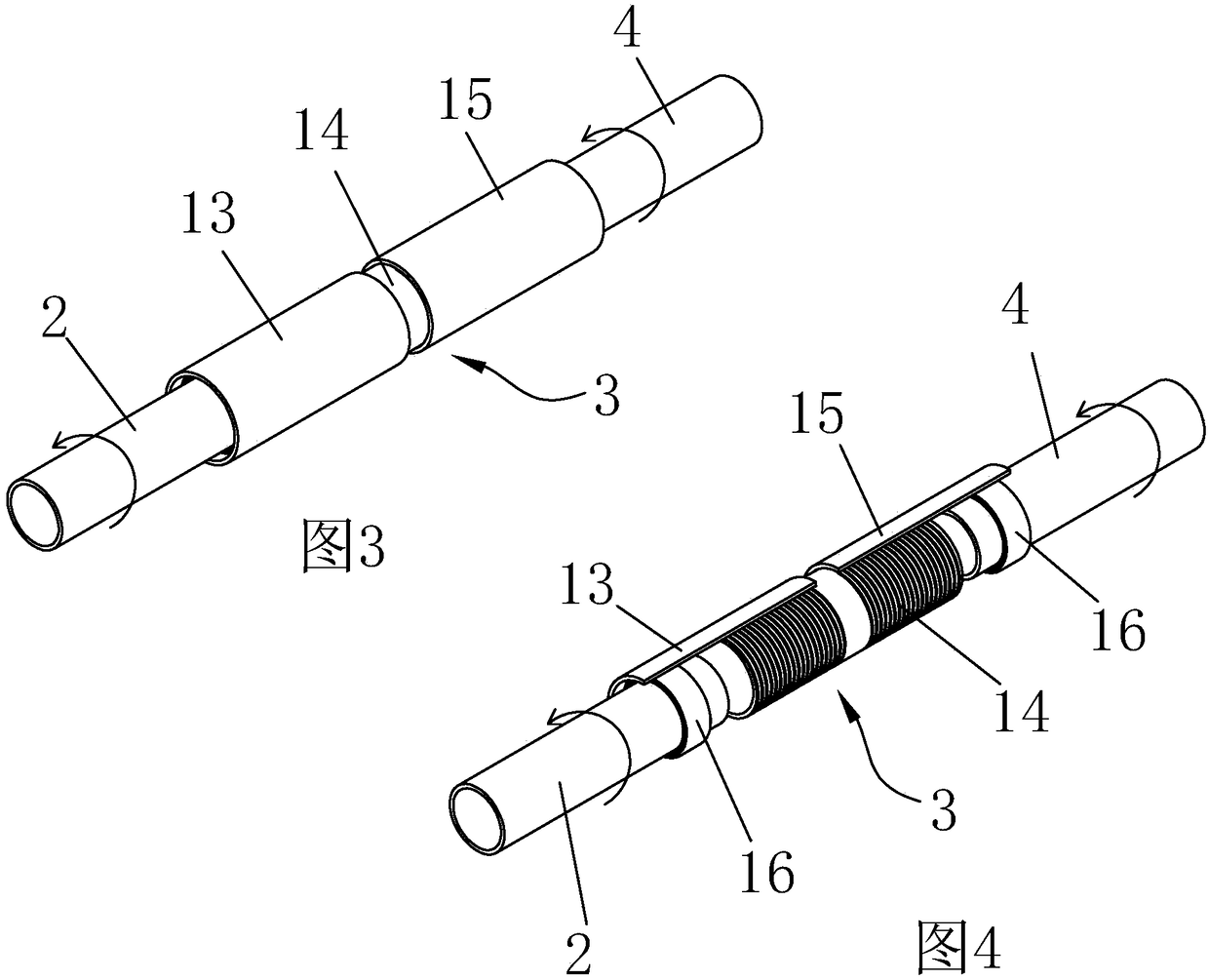

[0052] Such as figure 1 As shown, the upper end of the rotatable main beam is connected to the upper column I, the lower end of the rotatable main beam is connected to the lower column I, and the inner sides of the upper column I and the lower column I are respectively fixedly connected to the bearing I connected to the upper and lower ends of the rotatable main beam. In this embodiment, the rotatable main beam includes an upper rotatable main beam and a lower rotatable main beam, and a rotatable connector is connected between the upper rotatable main beam and the lower rotatable main beam. The lower outer wall of the rotatable connector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com