Temperature and humidity regulation system for flower breeding greenhouse

A temperature and humidity regulation, greenhouse technology, applied in energy-saving measures, agricultural machinery and equipment, climate change adaptation, etc., can solve the problems of uneven water intake, increased air humidity, high work intensity, etc., and achieve improved balance and intelligent adjustment. , the effect of sufficient heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

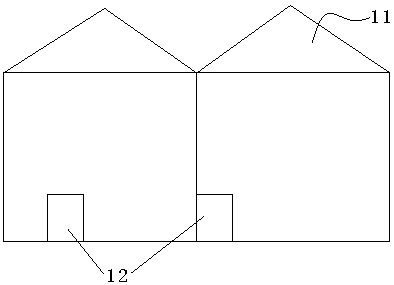

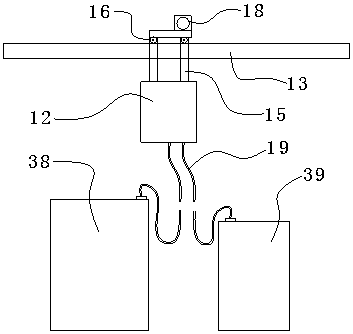

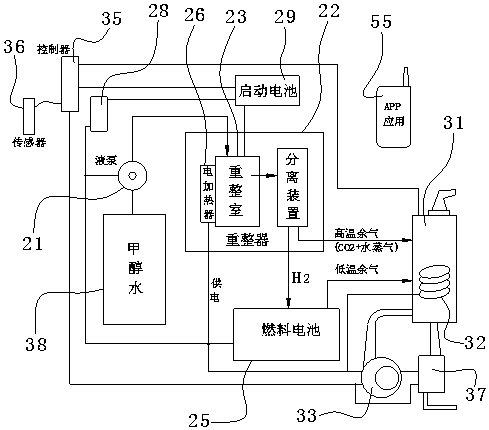

[0025] like Figure 1~Figure 3 As shown, the present invention is a flower cultivation greenhouse temperature and humidity adjustment system, which includes a scaffold located in the flower cultivation greenhouse, a plurality of temperature and humidity regulators 12 that are scattered or installed on the scaffold of the greenhouse 11 through rails. The temperature-humidity regulator 12 includes a liquid pump 21 for sucking the methanol-water raw material, a reformer 22 that connects the output port of the liquid pump with a pipeline and heats the methanol-water raw material to gasify and reform and separate it, and receives and separates the methanol-water raw material through a pipeline. Hydrogen and output battery residual gas and fuel cell 25 that generates electrical energy output, mixed gas blower 31 that receives separated r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com