Whole plant green maize automatic fermenting and transporting device for livestock and poultry

A transportation device and automatic fermentation technology, applied in the field of aquaculture, can solve problems such as no good solution, and achieve the effects of low cost, improved palatability, and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

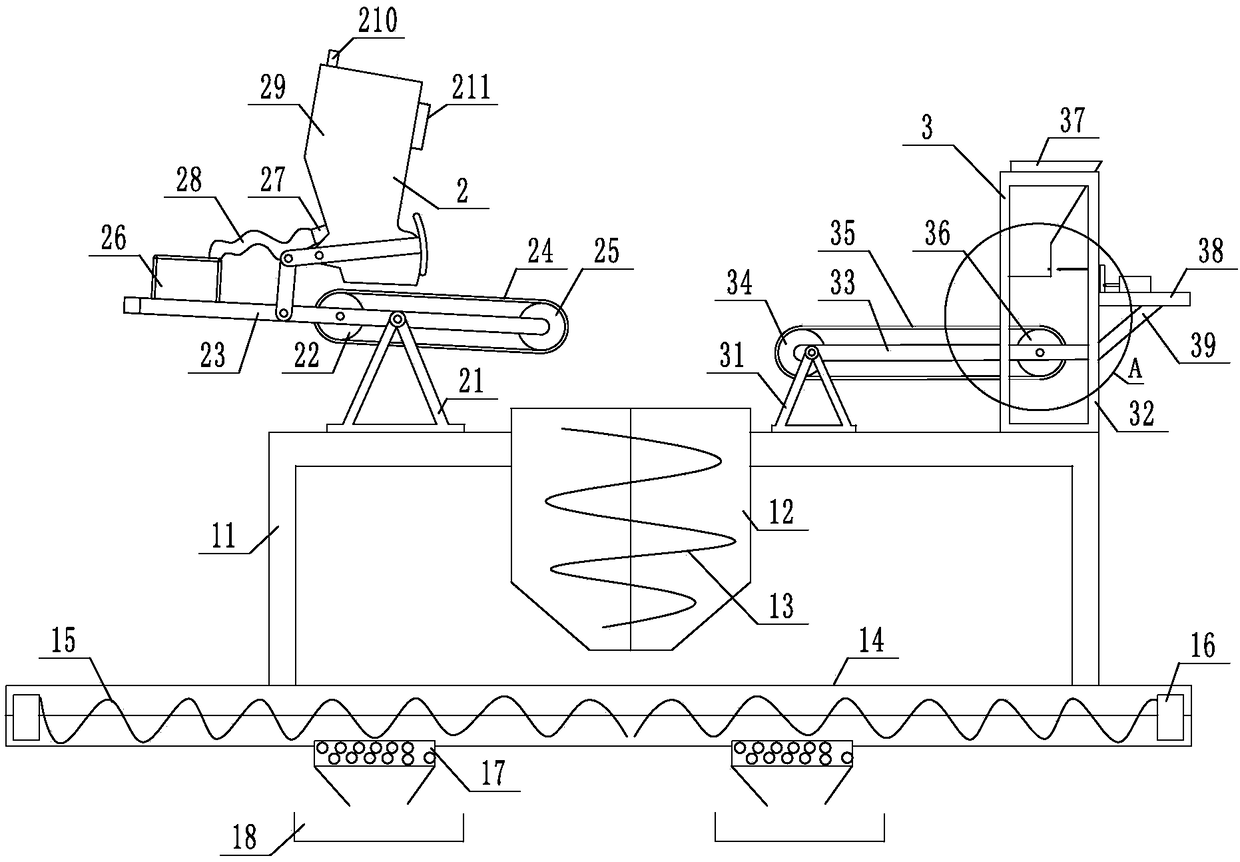

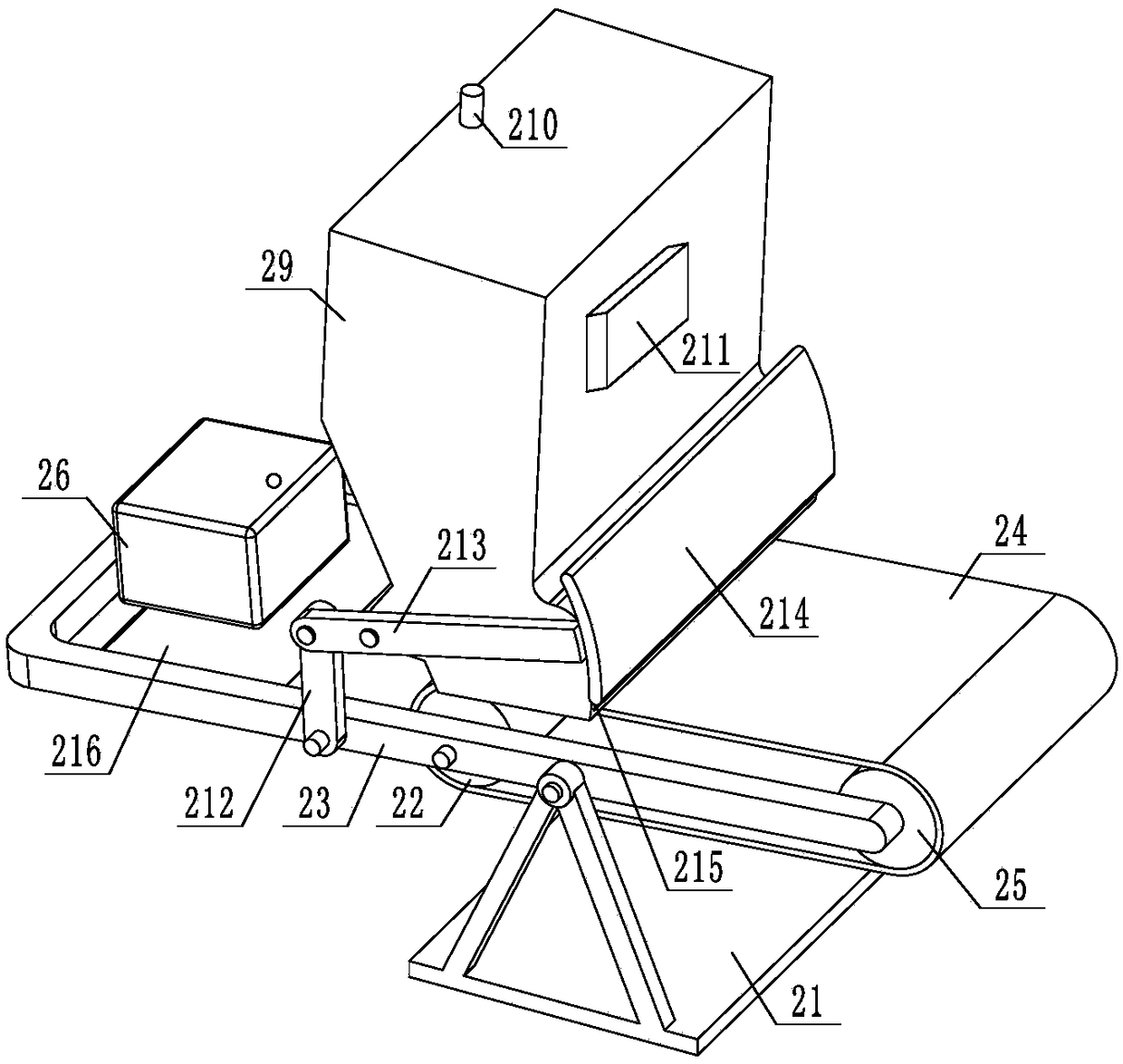

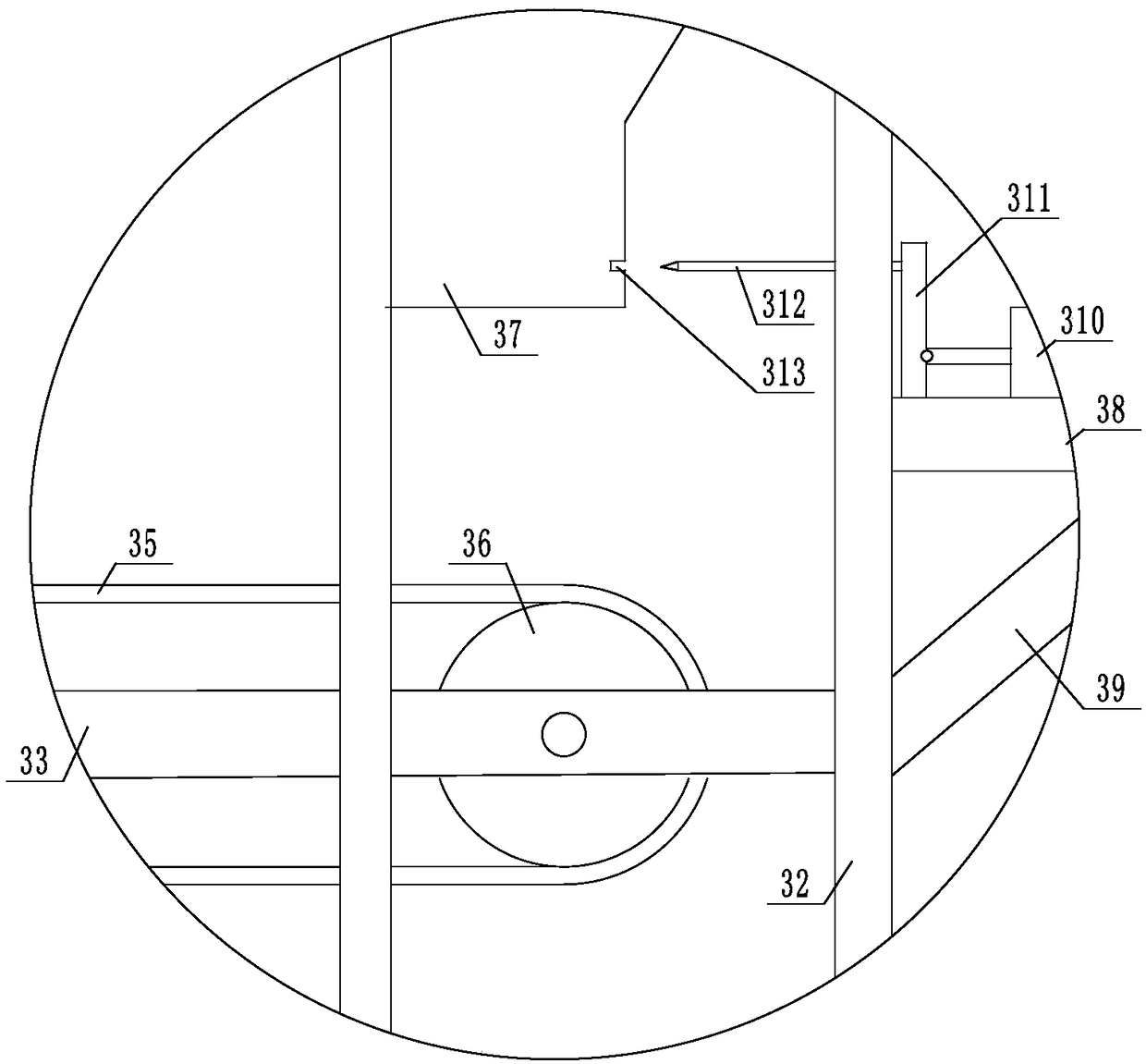

[0024] Such as Figure 1 to Figure 2 As shown, a whole-plant green corn automatic fermentation transportation device for livestock and poultry includes a large fixed frame, a mounting hole is provided in the middle of the large fixed frame, a middle mixing barrel 12 is provided in the mounting hole, and the middle stirring Stirrer shaft 13 is installed in the bucket, which is used to stir the green corn fermented wet material and dry material delivered here through the conveyor belt and then feed the livestock and poultry.

[0025] The bottom of the mixing barrel in the middle is provided with a discharge port, and a pipeline 14 is provided directly below the discharge port, and a plurality of screw conveyors are arranged in the pipeline, such as figure 1 As shown, in this embodiment, the pipeline is provided with a first screw conveyor 15 and a second screw conveyor 16 .

[0026] The conduit can be straight or circular. The pipeline is provided with a feed port, and the fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com