Degradable skin expander

A skin expansion and balloon technology, which is used in medical science, surgery, diagnosis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] S1-1 Dissolve degradable polyurethane (PU with propylene glycol as the initiator, random copolymerization of PDO and GA as the soft segment and lysine diisocyanate as the hard segment, with a number average molecular weight of 50,000-80,000) in chloroform solution , made into a 12-18% solution, and spun into an absorbable medical membrane with a pore size of 10-150 μm and a thickness of 0.1-0.4 mm by electrospinning technology;

[0042] S1-2 Evenly coating sodium hyaluronate gel or polyamino acid gel on the absorbable medical film obtained in step S1-1, drying or air-drying;

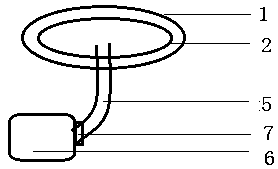

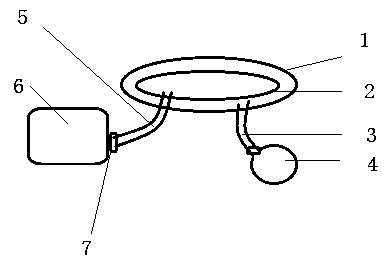

[0043] S1-3 Degradable polyurethane is dissolved in chloroform solution, and a breathable and impermeable film is made by solvent evaporation method. The membrane obtained in step S1-2 is spread on the breathable and impermeable surface, and after folding, the four sides are melted to form a dilator shape , which forms figure 1 A skin expander with tissue-inducing functionality is shown.

Embodiment 2

[0045] S2-1 Dissolve degradable polyurethane (with PEG400 as the initiator, PDO and LA randomly copolymerized as soft segment, lysine diisocyanate as hard segment PU, number average molecular weight 80,000-100,000) in chloroform solution , made into a 10-15% solution, and spun into a membrane with a pore size of 10-150 μm and a thickness of 0.05-0.1 mm by electrospinning technology, and evenly coated with a layer of polylysine PU (first formulated with 1% hydrogel glue for use), that is, the absorbable medical film;

[0046] S2-2 The degradable polyurethane is dissolved in chloroform solution, and the air-permeable and water-impermeable film is made by the solvent evaporation method. The absorbable medical film obtained in step S2-1 is spread on the air-permeable and water-impermeable film, and the four sides are melted after folding. dilator shape, that forms figure 1 A skin expander with tissue-inducing functionality is shown.

Embodiment 3

[0048] S3-1 Make PLGA (number average molecular weight 50,000, LA:GA=6:4) into 15-20% chloroform solution, and use electrospinning technology to spin it into a product with a pore size of 100-300μm and a thickness of 0.2-0.3mm film, made of absorbable medical film;

[0049] S3-2 Dissolve degradable polyurethane (PU with PEG200 as the initiator, random copolymerization of CL and LA as the soft segment and lysine diisocyanate as the hard segment, with a number average molecular weight of 60,000-80,000) in chloroform solution , made into a 10-15% solution, and made into a breathable and water-impermeable film by solvent evaporation, and the absorbable medical film obtained in step S3-1 was spread on the air-permeable and water-impermeable film, folded and melted on all sides to form a dilator shape , which forms figure 1 A skin expander with tissue-inducing functionality is shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com