A solid material filtrate feeding structure

A material and filtrate technology, applied in the field of solid material filtrate feeding structure, can solve the problems of toxic gas, irritating gas, lower teaching quality, no concrete understanding, etc., and achieve the effect of safe operation of dangerous substance reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

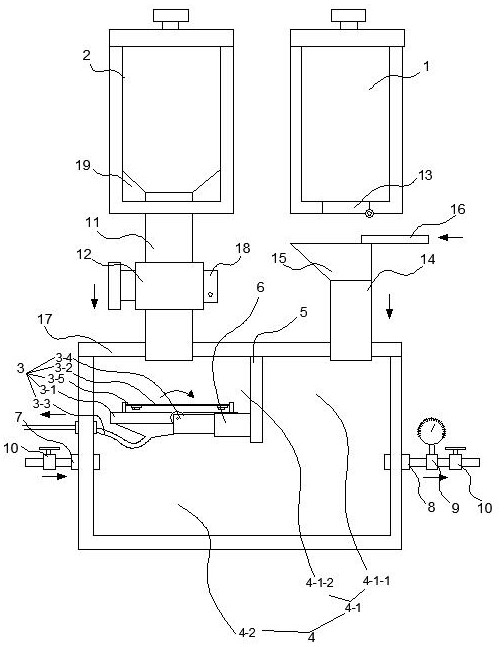

[0017] The present invention will be further described in detail below with reference to the accompanying drawings.

[0018] The embodiment of the present invention is used for the reaction operation and observation of solid substances in an isolated environment, such as figure 1 As shown, the embodiment of the present invention includes a dry storage box 1 for storing solid reaction substances in a dry environment, a liquid storage box 2 for storing solid reaction substances by protecting the liquid from air, and a liquid storage box 2 for storing liquid The protective liquid on the surface of the material in the type storage box 2 is separated out and then the filter disc 3 and the reaction box 4 used as a reaction container, the dry storage box 1, the liquid storage box 2 and the reaction box are 4 is made of transparent glass material so that the operator can observe the entire operation process of the reaction from the outside. The material section 4-1 must be set above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com