Reactor and method for realizing chlorosilane synthesis

A technology for reactors and chlorosilanes, applied in the field of reactors for the synthesis of chlorosilanes, can solve the problems of high energy consumption, easy pollution, complex structure, etc., and achieve the effects of temperature control, easy operation, and investment saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

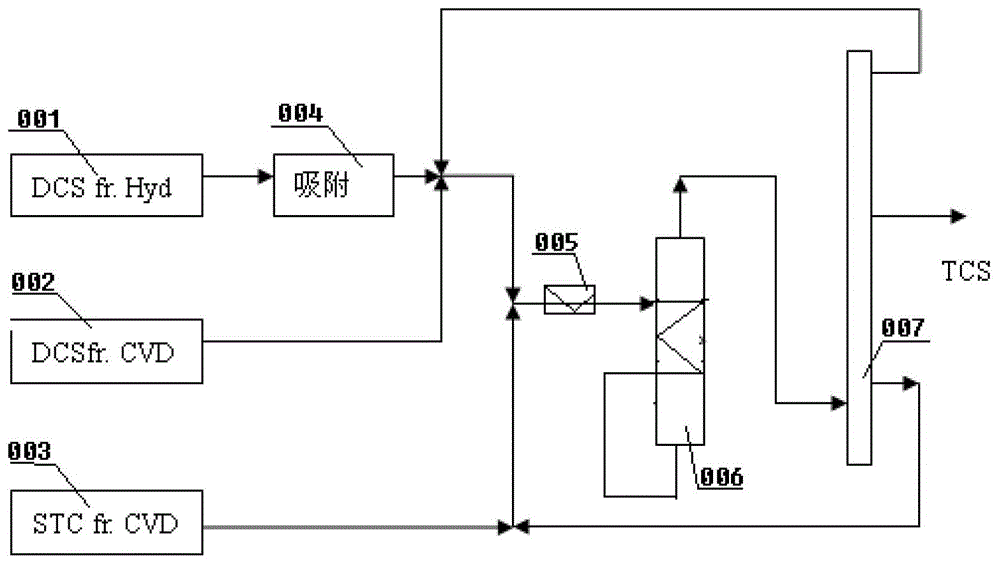

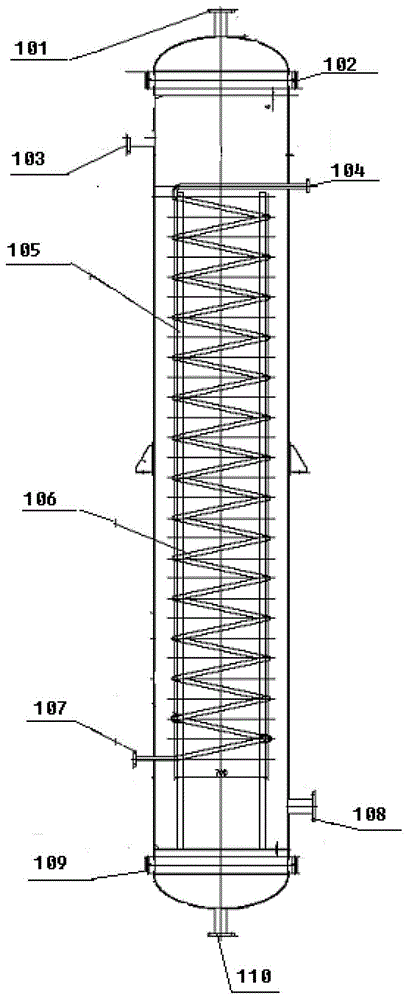

[0087] figure 1 The reaction flow chart of the synthesis of trichlorosilane from dichlorodihydrogensilane and silicon tetrachloride provided in Example 1; figure 2 It is an enlarged view of the reactor chamber in Example 1.

[0088] This embodiment discloses a reactor for realizing the synthesis of chlorosilanes, the specific structure is as follows figure 1 with figure 2As shown, the reactor includes a reactor cavity 006, and the reactor cavity 006 is provided with a catalyst charging port 103, a catalyst charging port 108, a raw material feeding port 110, and a product discharging port 101;

[0089] A heat exchange device is arranged in the reactor cavity 006, and the heat exchange medium outlet 107 and the heat exchange medium inlet 104 of the heat exchange device are both arranged on the reactor cavity 006, and the heat exchange medium outlet 107 of the heat exchange device is connected with the raw material inlet The feed port 110 is connected.

[0090] The upper an...

Embodiment 2

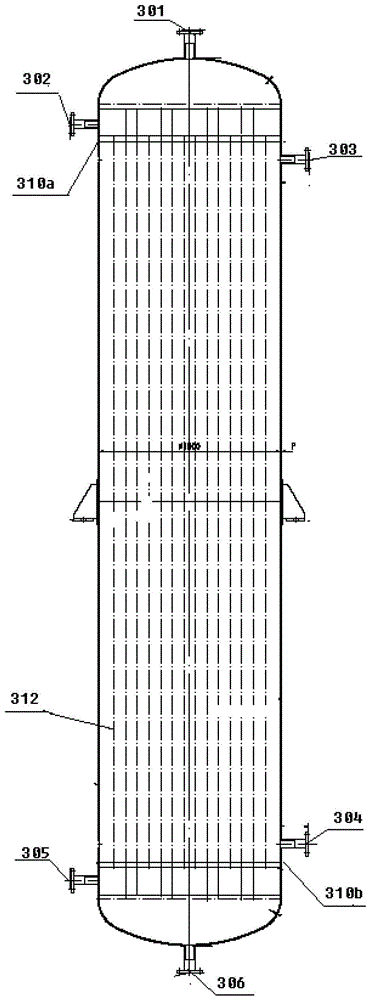

[0103] image 3 It is an enlarged view of the reactor chamber of Example 2.

[0104] The invention discloses a reactor for realizing the synthesis of chlorosilanes. The difference from Example 1 is that the heat exchange device used in this example is as follows: image 3 As shown: the heat exchange device is a plurality of parallel heat exchange tubes arranged along the length direction of the reactor cavity. A double tube sheet structure is adopted between the end of the heat exchange tube and the reactor cavity, and the double tube sheet structure makes it difficult for the fluid in the heat exchange tube and the fluid in the reactor cavity to mix.

[0105] Refer to Example 1 for the basic process of the deproportionation reaction of chlorosilanes in this example.

Embodiment 3

[0107] Figure 4 Reaction scheme provided for Example 3.

[0108] This embodiment opens a kind of reactor that realizes the synthesis of chlorosilane, and the structural diagram of this reactor is as follows Figure 4 As shown, it includes a reactor cavity, a raw material delivery pipeline 401 for delivering raw materials, and a product output pipeline 402 for delivering products. The reactor cavity is provided with a catalyst charging port, a catalyst charging port, a second A feed port 405 and a second feed port 406;

[0109] The reactor cavity is provided with a built-in or an external preheating mechanism;

[0110] A first temperature sensing mechanism 415 is provided at one end of the reactor cavity close to the first feed port 405; a second temperature sensing mechanism 416 is provided at one end of the reactor cavity close to the second feed port 406 ;

[0111] The first feed inlet 405, the raw material delivery pipeline 401 and the product output pipeline 402 are c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com