Internal and external concrete moisture migration inhibitor

A technology for migration inhibition and in-concrete, which is applied in the field of concrete admixtures to reduce surface energy, increase contact angle, and reduce drying shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

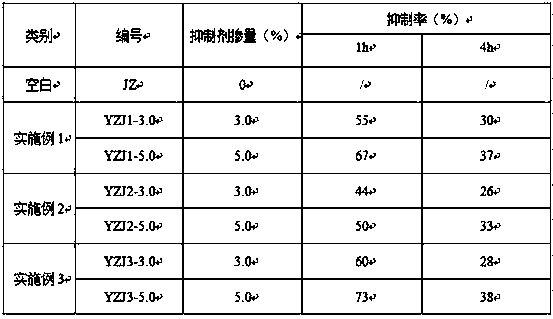

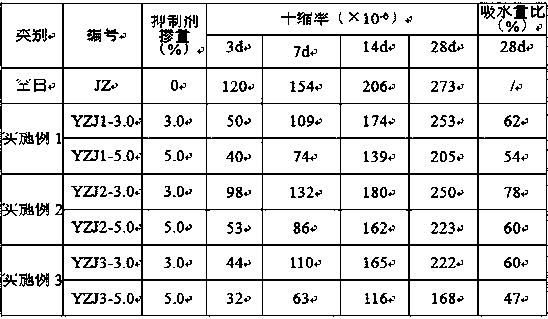

Examples

Embodiment 1

[0022] The moisture migration inhibitor inside and outside the concrete of the present invention is prepared by the following method from raw materials muscovite powder, mordenite and kaolin:

[0023] (1) Substrate preparation: Grind the commercially available muscovite powder to 400 mesh, dry it for later use; grind the commercially available natural mordenite to 300 mesh, and the ammonium absorption value is not less than 130mmol / 100g; commercially available Kaolin is calcined at 750°C~800°C and ground to a fineness of 500 mesh, of which SiO 2 The content is not less than 50%, Al 2 o 3 The content is not less than 40%, and the specific surface area is not less than 15000m2 2 / kg. Take 60g of mica powder, 10g of zeolite powder, and 30g of kaolin powder after the above-mentioned treatment, and mix them uniformly in a high-speed powder mixer to prepare a base material;

[0024] (2) Ultrasonic treatment: Take 50g of the base material, add it into the mixture of isopropanol a...

Embodiment 2

[0029] The moisture migration inhibitor inside and outside the concrete of the present invention is prepared by the following method from raw material muscovite powder and mordenite:

[0030] (1) Substrate preparation: commercially available muscovite powder is ground to 400 mesh, dried for later use; commercially available natural mordenite is ground to 300 mesh, and the ammonium absorption value is not less than 130mmol / 100g. Take 70g of treated mica powder and 30g of zeolite powder, mix them evenly in a high-speed powder mixer, and prepare them as substrates;

[0031] (2) Ultrasonic treatment: Take 50g of the base material, add it into the mixture of isopropanol and n-butanol (volume ratio 1:1), ultrasonically treat for 10min, and then magnetically stir for 10min;

[0032] (3) Modification treatment: Slowly add 4ml of KH-550 silane coupling agent with a pipette gun under the state of magnetic stirring, and continue to stir for 30 minutes; appropriately increase the speed of...

Embodiment 3

[0036]The moisture migration inhibitor inside and outside the concrete of the present invention is prepared by the following method from raw material muscovite powder and commercially available kaolin:

[0037] (1) Substrate preparation: commercially available muscovite powder, ground to 1000 mesh, dried for later use; commercially available kaolin was calcined at 750°C to 800°C, and ground to a fineness of 500 mesh, of which SiO 2 The content is not less than 50%, Al 2 o 3 The content is not less than 40%, and the specific surface area is not less than 15000m2 2 / kg. Take 50g of mica powder and 50g of kaolin powder after the above treatment, and mix them uniformly in a high-speed powder mixer to prepare a base material;

[0038] (2) Ultrasonic treatment: Take 50g of the base material, add it into the mixture of isopropanol and n-butanol (volume ratio 1:1), ultrasonically treat for 10min, and then magnetically stir for 10min;

[0039] (3) Modification treatment: Slowly add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com