A growth method of organic single crystal microribbon p-n heterojunction array

A growth method and micro-belt technology, which is applied in single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of difficult to control the accurate growth of upper layer materials, and the inability to accurately locate single crystal materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

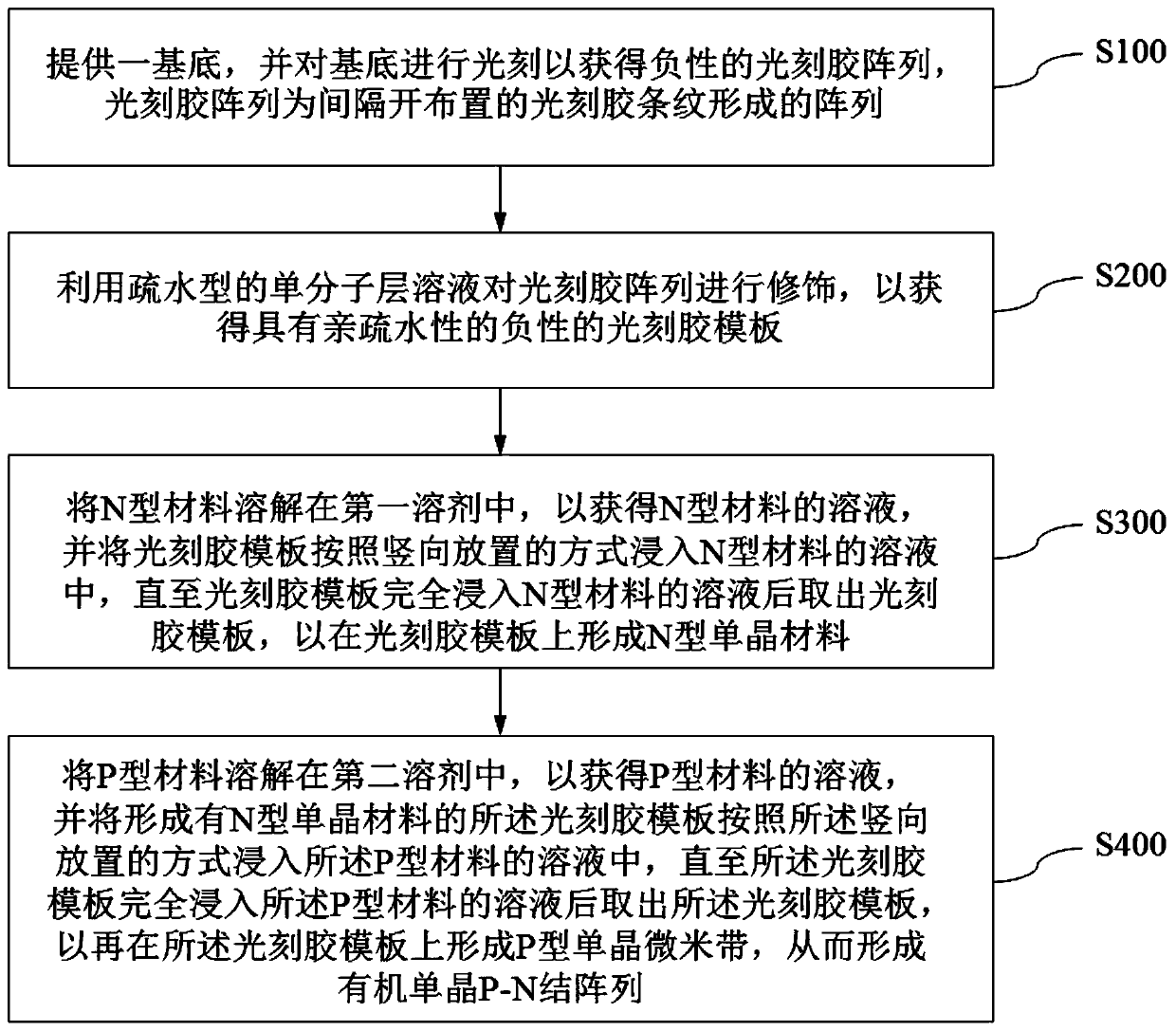

[0031] figure 1 It is a schematic flowchart of a method for growing an organic single crystal microbelt P-N heterojunction array according to an embodiment of the present invention. Such as figure 1 As shown, the growth method includes the following steps:

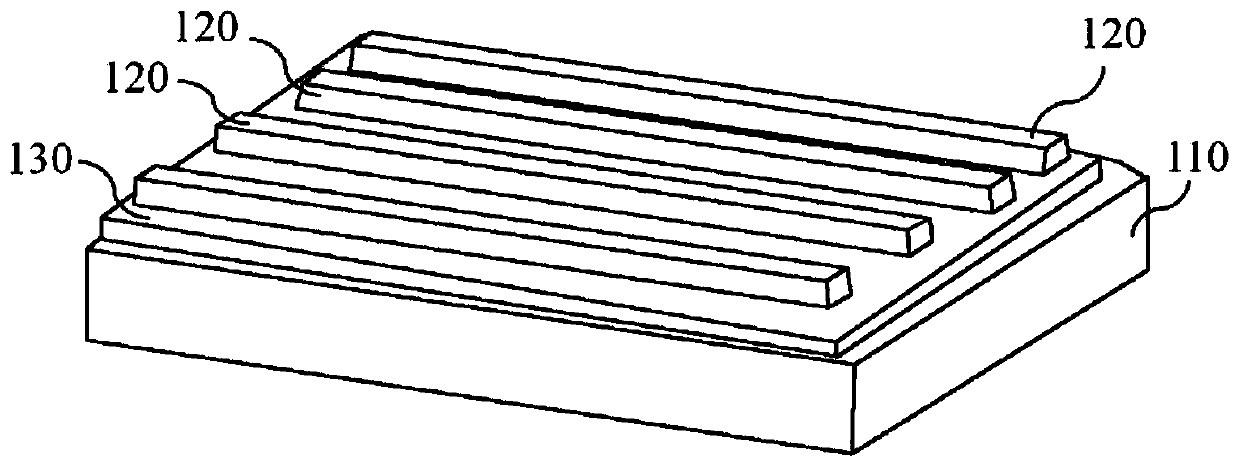

[0032] S100. Provide a substrate, and perform photolithography on the substrate to obtain a negative photoresist array. The photoresist array is an array formed by a plurality of photoresist stripes arranged at intervals;

[0033] S200: Use a hydrophobic monolayer solution to modify the photoresist array to obtain a negative photoresist template with hydrophilicity and hydrophobicity;

[0034] S300. Dissolve the N-type material in the first solvent to obtain a solution of the N-type material, and immerse the photoresist template in the solution of the N-type material in a vertical manner until the photoresist template is completely immersed in the N-type material. After the material solution, the photoresist template is taken ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com