High-frequency IGBT power supply of plasma and water electrolytic separation equipment

A technology of plasma and separation equipment, applied in the field of thermochemical reaction burners, can solve the problems of bulkiness, low efficiency, low efficiency of power frequency power supply, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

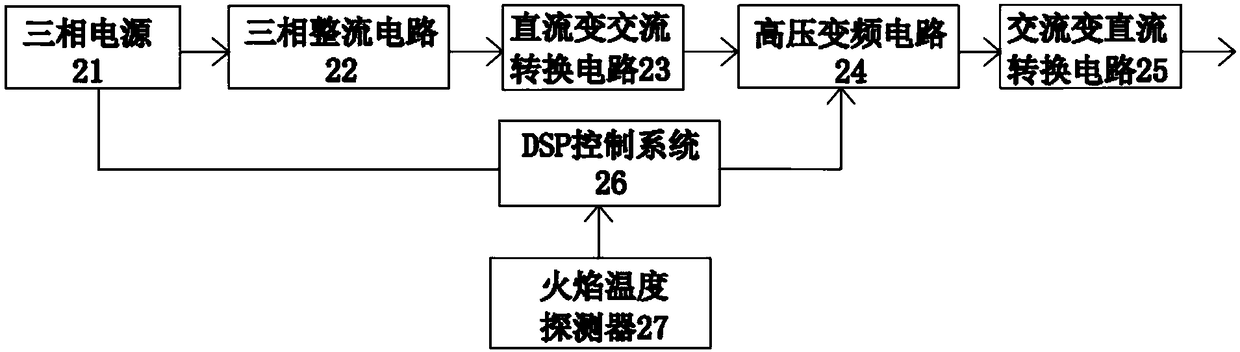

[0029] refer to figure 2 As shown, a high-frequency IGBT power supply for plasma and water electrolysis separation equipment includes a three-phase power supply 21 connected in sequence, a three-phase rectifier circuit 22, a DC-to-AC conversion circuit 23, a high-frequency transformer circuit 24, and an AC-to-DC circuit. Conversion circuit 25; it also includes a control system 26 and a flame temperature detector 27 that inputs signals to the control system; the control system 27 is connected to the high-frequency transformer circuit 24. Wherein, the above-mentioned control system 26 is a DSP control system.

[0030] Wherein, the working steps of the high-frequency IGBT power supply are as follows: the electrical signal that changes with the combustion temperature of the flame temperature detector 27 in application is output to the control system 26, and the control system 26 transmits the signal according to the received flame temperature detector 27. The electrical signal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com